A culture device for suspended tissue cells

A culture device and technology for suspending tissue, which is applied in tissue cell/virus culture devices, general culture methods, 3D culture, etc., can solve problems such as unfavorable normal cell growth, cell damage, slowing down of cell growth, etc., to ensure smooth and normal The effect of growth, uniform distribution of cells, and convenience for normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

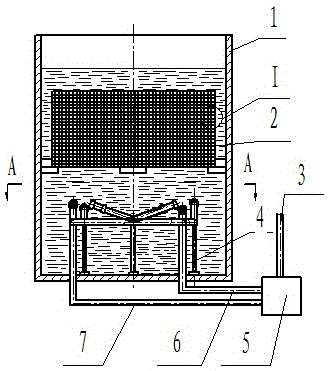

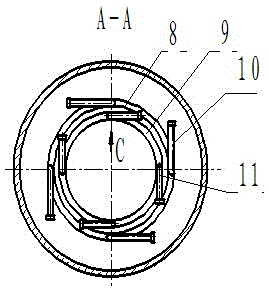

[0044] Referring to the accompanying drawings, a culture device for suspending tissue cells includes a tissue cell culture body 2, which is a porous tantalum material; the porous tantalum material is based on the material pore size The grading cavity and the cavity wall surrounding the cavity are formed, and the lower-level small cavity is set around the cavity wall forming the upper-level large cavity; the cavities of each level are connected to each other, and the cavities of each level are also connected to each other. . The culture device also includes a cyclone device placed therein.

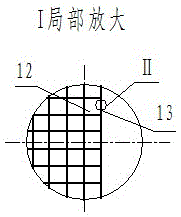

[0045] Specifically in this example, the porous tantalum material has three-level cavities, wherein the upper two-level large cavities 12 (hereinafter referred to as the first-level cavities) that are uniformly distributed and interpenetrated have uniformly distributed, Interconnected upper-level large cavities 14 (hereinafter referred to as second-level cavities), and evenly distributed a...

Embodiment 2

[0059] The cell culture body 2 of the tissue cell culture device of this embodiment is made of porous silica material, has two-stage cavities, uniformly distributed and interpenetrated upper-level macro-cavities 12 have evenly distributed and inter-connected lower-level cavities on the cavity wall 13 small cavity 14, and the two-stage cavity also communicates with each other. The pore diameter of the upper large cavity 12 is 20µm-80µm, and the pore diameter of the lower small cavity 14 is 100nm-300nm. The included angles θ1 and θ2 of outlet pipe ① 11, outlet pipe ② 12 and the horizontal plane are 15°, outlet pipe ① 11, outlet pipe ② 12 are equipped with a perforated diaphragm 16, and its average aperture is 0.3mm.

[0060] The preparation method of this kind of porous silicon dioxide material is:

[0061] (1) Material preparation

[0062] Use 1µm-10µm silica powder and urea with a particle size of 130nm-350nm as the smallest pore-forming agent, mix them evenly, and use 130nm...

Embodiment 3

[0070] The cell culture body 2 of the tissue cell culture device of this embodiment is made of porous titanium material and has three-level cavities, among which, the cavities of the upper two-level large cavities 12 (hereinafter referred to as the first-level cavities) that are uniformly distributed and interpenetrating On the wall 13 there are evenly distributed and interconnected upper-level large cavities 14 (hereinafter referred to as second-level cavities), and on the wall 15 of the upper-level large cavities there are evenly distributed and inter-connected lower-level small cavities ( Hereinafter referred to as the third-level cavity); and the cavities of all levels are also connected to each other. The aperture of the first-stage cavity 12 is 300µm-700µm, the aperture of the second-stage cavity 14 is 60µm-95µm, and the aperture of the third-stage cavity is 400nm-700nm. Be 45 °, air outlet pipe 1. 11, outlet pipe 2. 12 outlets are equipped with apertured diaphragm 16, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com