Waterproof and oil-proof white cardboard and production method thereof

A waterproof and oil-proof, white cardboard technology, applied in the field of papermaking, can solve the problems affecting paper recycling and natural degradation, endangering human health, pulping and pulping difficulties, etc., to improve surface smoothness and gloss, improve Surface properties, effects of migration avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

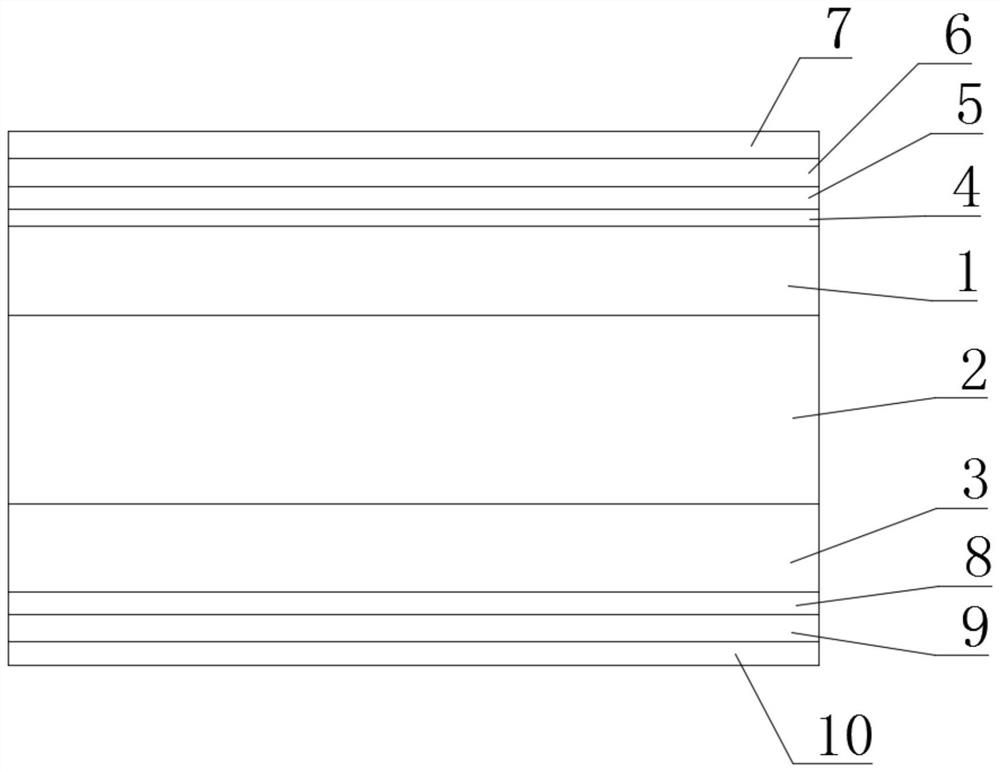

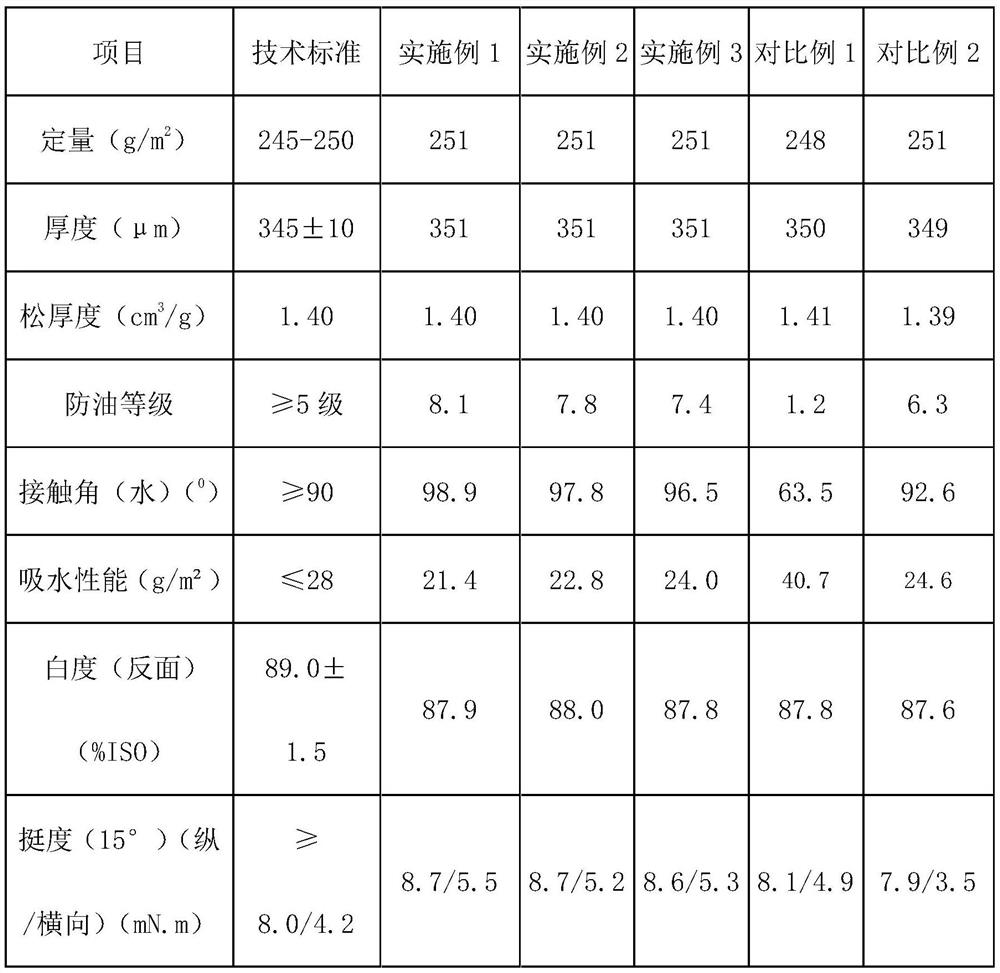

[0029] A waterproof and oil-proof white cardboard with a basis weight of 250g / m 2 ,Such as figure 1 As shown, it includes a surface layer 1, a core layer 2 and a bottom layer 3 stacked in sequence. The surface layer 1 is coated with a precoat 5, a core coating 6 and a topcoat 7 in sequence from the inside to the outside. The bottom layer 3 is coated with a base coat 9, which is also coated with a waterproof and oil-repellent coating (corresponding to figure 1 The waterproof and oil-proof coating 10) in the surface layer, the slurry of the core layer and the bottom layer are all added with a slurry internal sizing agent, and the surface layer sizing agent is coated between the surface layer and the precoat (correspond figure 1 The surface layer sizing layer 4) in the bottom layer is coated with a bottom layer sizing agent (corresponding to figure 1 The bottom sizing layer in 8).

[0030] The pulp of the surface layer 1 is a combination of NBKP pulp and LBKP pulp, the pulp o...

Embodiment 2

[0050] The structure, weight, and papermaking process of the white cardboard base paper are the same as in Example 1, and they come from the same wet-end papermaking production line. The processes and formulas of surface sizing, precoating, core coating, and top coating are also the same. at:

[0051] The paint of the primer layer comprises the following components: by weight, 100 parts of filler, 7 parts of carboxylated styrene-butadiene latex, 5 parts of bio-latex, 2 parts of soybean protein isolate, 0.1 part of water-resistant agent, 0.03 part of dispersant, lubricating 0.2 parts of agent, 0.4 parts of CMC, 1.0 parts of OBA whitening agent, 0.0015 parts of coating brand blue and appropriate amount of defoaming agent.

[0052] The waterproof and oil-repellent paint comprises the following components in parts by mass: 35 parts of nitrile latex, 18 parts of silicon acrylic emulsion, 25 parts of oxidized starch, 8 parts of paraffin wax emulsion, 1.5 parts of CMC, starch crossli...

Embodiment 3

[0054] All the other are identical with embodiment 1, difference is:

[0055] The coating of described base coat comprises following components: by weight, 100 parts of fillers, 8 parts of carboxylated styrene-butadiene latex, 4 parts of bio-latex, 1.5 parts of soy protein isolate, 0.12 parts of water-resistant agent, 0.03 part of dispersant, lubricating agent 0.15 parts of agent, 0.3 parts of CMC, 1.0 parts of OBA brightener, 0.0015 parts of coating brand and appropriate amount of defoamer.

[0056] The waterproof and oil-repellent coating comprises the following components in parts by mass: 35 parts of nitrile latex, 15 parts of silicon acrylic emulsion, 30 parts of oxidized starch, 7 parts of paraffin wax emulsion, 1.5 parts of CMC, starch crosslinking agent, preservative, disinfectant Appropriate amount of foaming agent. The dosage of the starch crosslinking agent is 0.18% of the weight of the oxidized starch, and the starch crosslinking agent is sodium trimetaphosphate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com