Compound nano cobalt-free hard alloy-polycrystalline cubic boron nitride film and manufacturing method thereof

A cubic boron nitride and cemented carbide technology, applied in chemical instruments and methods, metal layered products, layered products, etc., can solve problems such as the reduction of the hardness of the cubic boron nitride layer, achieve high hardness, reduce residual High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The technological process of the manufacturing method of the nano cobalt-free cemented carbide-cubic boron nitride polycrystalline composite sheet of the present invention is as follows:

[0030] (1) Select ordinary cubic boron nitride for gradation combination, and carry out vacuum heating ion purification;

[0031] (2) Get nano-cubic boron nitride to account for 90% of the total mass, and nano-ceramic binder titanium carbide to account for 10% of the total mass, put them into a multidimensional high-energy ball mill and mix the ingredients for 30 minutes under an argon environment to mix and disperse Uniform, and then vacuum heating ion purification again;

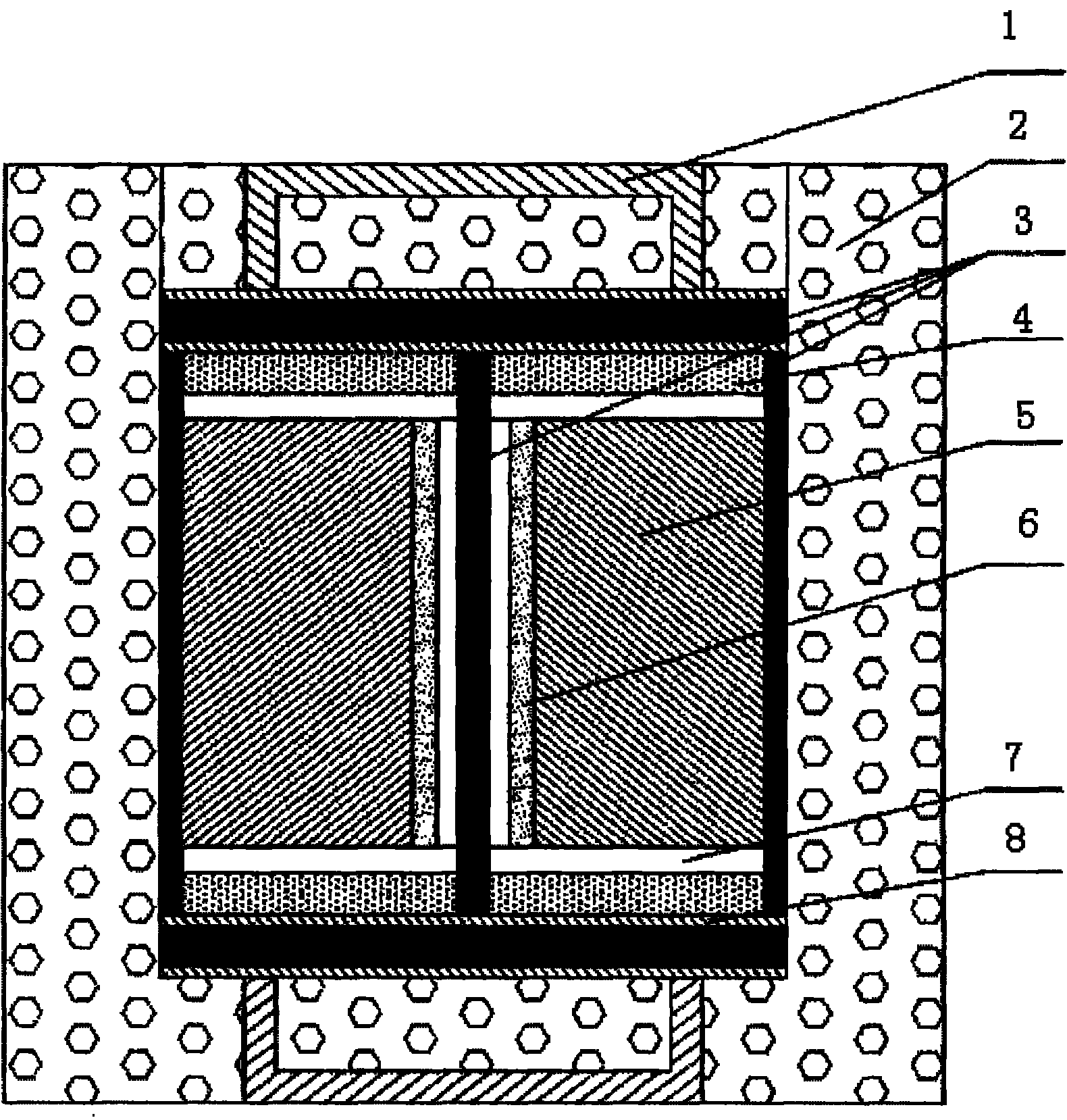

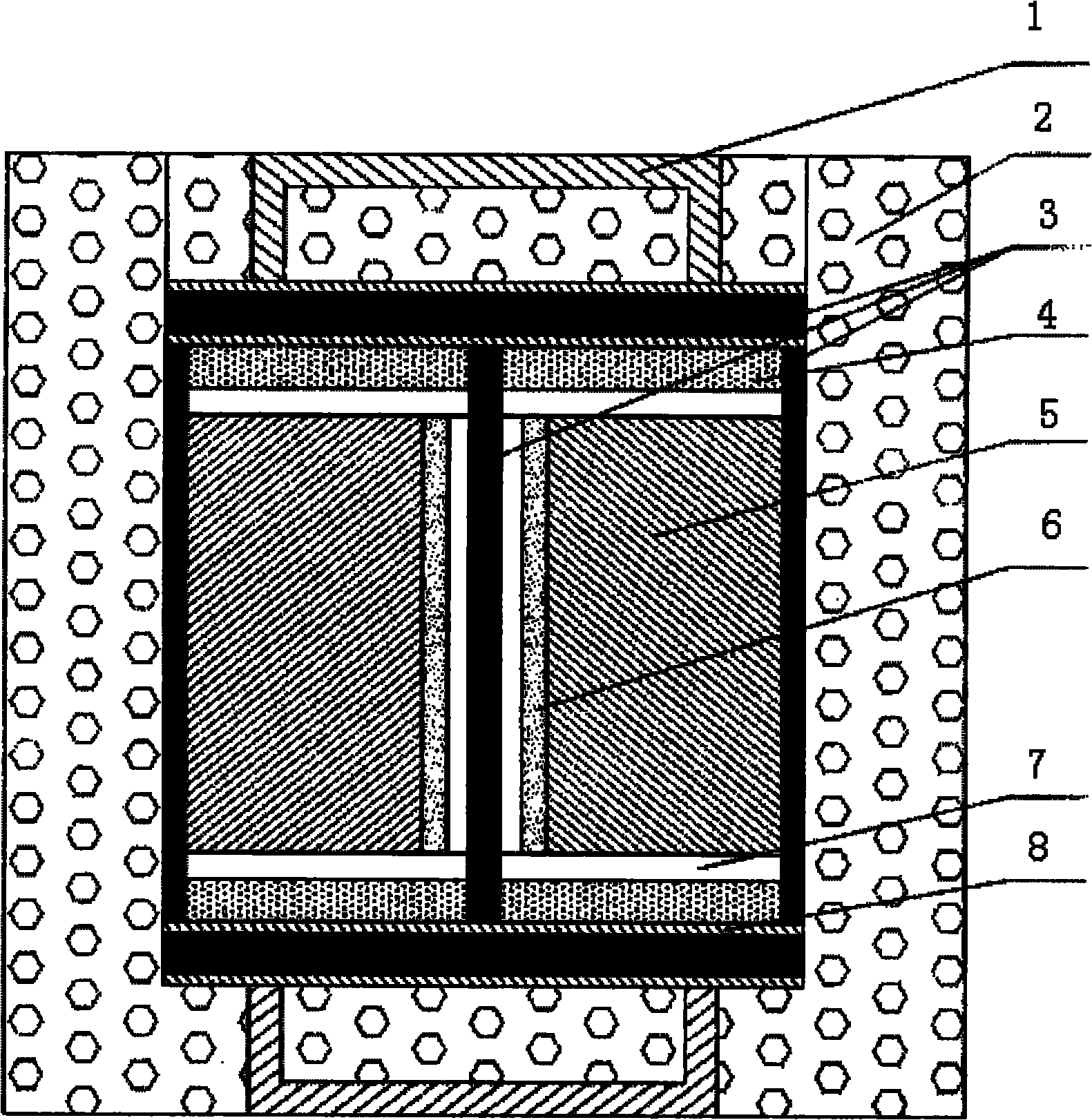

[0032] (3) After the mixed molding material is press-molded and assembled with the nano-cobalt-free cemented carbide, it is assembled according to the assembly method in the accompanying drawing. First put the salt tube 7 and coat the MgO tube 4, place the square graphite sheet 3 and the steel sheet alternately o...

Embodiment 2

[0036] The technological process of the manufacturing method of the nano cobalt-free cemented carbide-cubic boron nitride polycrystalline composite sheet of the present invention is as follows:

[0037] (1) Select cubic boron nitride of 5-100 nanometers for gradation combination, and perform vacuum heating ion purification;

[0038] (2) Get nano-cubic boron nitride to account for 80% of the total mass, nano-ceramic bond titanium nitride to account for 15% of the total mass, and bond alloy aluminum to account for 5% of the total mass and put it into a multidimensional high-energy ball mill in an argon environment Mix the ingredients for 35 minutes to make the mixture evenly dispersed, and then carry out vacuum heating and ion purification again;

[0039] (3) After the mixed molding material is press-molded and assembled with the nano-cobalt-free cemented carbide, it is assembled according to the assembly method in the accompanying drawing. First put the salt tube 7 and coat th...

Embodiment 3

[0043] The technological process of the manufacturing method of the nano cobalt-free cemented carbide-cubic boron nitride polycrystalline composite sheet of the present invention is as follows:

[0044] (1) Select cubic boron nitride with a particle size of 5 to 100 nanometers for gradation combination, and perform vacuum heating ion purification;

[0045] (2) Take nano cubic boron nitride to account for 70% of the total mass, nano-ceramic binder titanium carbide to account for 20% of the total mass, and the mixed powder of bonding alloy aluminum, nickel, antimony, tin, and magnesium to account for 1% of the total mass , the mixed powder of rare earth elements cerium, neodymium and gadolinium accounted for 4% of the total mass of the cubic boron nitride layer, put it into a multi-dimensional high-energy ball mill and mixed the materials for 40 minutes in an argon environment to make the mixing and dispersion uniform, and then vacuum again heating ion purification;

[0046](3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com