Preparing method for zirconium boride dispersion strengthening tungsten powder

A technology of dispersion strengthening and zirconium boride, which is applied in the field of metal tungsten powder preparation, can solve the problems of easy introduction of impurities, high energy consumption, and long cycle of dispersing tungsten powder, so as to increase the specific surface area, improve the degree of dispersion, and facilitate reduction and The effect of sintering densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of 0.2% ZrB2 tungsten

[0026] 1. Precursor solution preparation

[0027] 1) Take 100ml of deionized water, add 27.6g of AMT (corresponding to 20g of tungsten powder), 0.5g of PVP, stir evenly, and add dropwise ammonia until the pH is 11.

[0028] 2) Add the zirconium boride to be dispersed into the solution according to the mass percentage of 0.2%, and stir it evenly. Disperse in ultrasonic for 0.1h. A precursor dispersion is obtained.

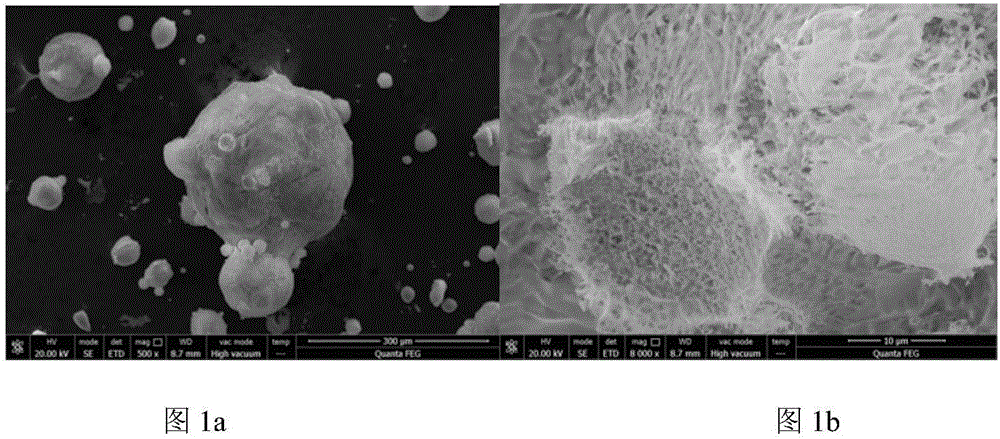

[0029] 2. Precursor freezing and drying

[0030] The precursor dispersion liquid is sprayed into a container filled with liquid nitrogen in a spray manner using an atomized nozzle, collected and dried in a vacuum dryer to obtain a precursor powder.

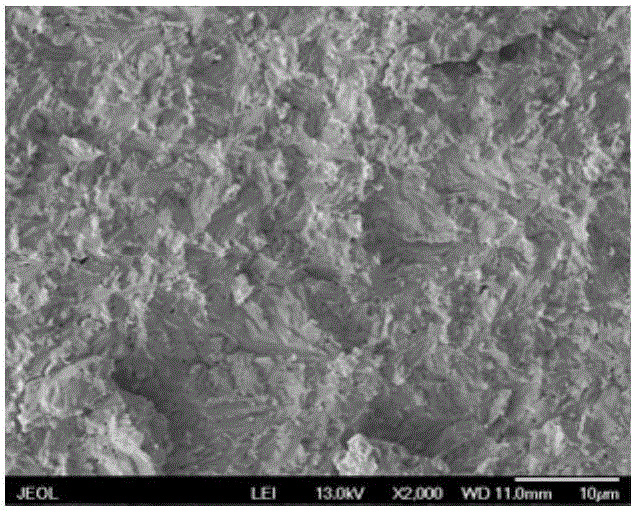

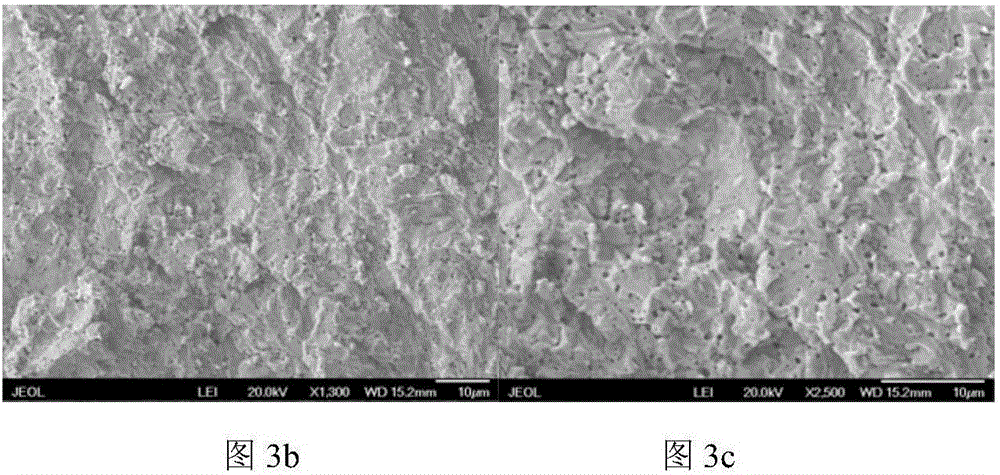

[0031] 3. Calcination and reduction of precursor

[0032] The doped precursor was calcined in an argon atmosphere at 400° C. for 0.5 h. The PVP in the frozen precursor is decomposed and removed to obtain doped tungsten oxide, while avoiding the oxidation of zirconium boride. ...

Embodiment 2

[0033] Example 2: Preparation of 0.5% ZrB2 tungsten

[0034] 1. Precursor solution preparation

[0035] 1) Take 100ml of deionized water, add 27.6g of AMT (corresponding to 20g of tungsten powder), 1g of PVP, stir evenly, and add ammonia water dropwise to pH 12.

[0036] 2) Add the zirconium boride to be dispersed into the solution according to the mass percentage of 0.5%, and stir it evenly. Disperse in ultrasonic for 0.2h. A precursor dispersion is obtained.

[0037] 2. Precursor freezing and drying

[0038] The precursor dispersion liquid is sprayed into a container filled with liquid nitrogen in a spray manner using an atomized nozzle, collected and dried in a vacuum dryer to obtain a precursor powder.

[0039] 3. Calcination and reduction of precursor

[0040] The doped precursor was calcined in an argon atmosphere at 450° C. for 0.5 h. The PVP in the frozen precursor is decomposed and removed to obtain doped tungsten oxide, while avoiding the oxidation of zirconium boride. The d...

Embodiment 3

[0041] Example 3: Preparation of 1% ZrB2 tungsten

[0042] 1. Precursor solution preparation

[0043] 1) Take 100ml of deionized water, add 27.6g of AMT (corresponding to 20g of tungsten powder), 2g of PVP, stir evenly, and add ammonia water dropwise to pH 13.

[0044] 2) Add the zirconium boride to be dispersed into the solution according to the mass percentage of 1%, and stir it evenly. Disperse in ultrasound for 0.5h. A precursor dispersion is obtained.

[0045] 2. Precursor freezing and drying

[0046] The precursor dispersion liquid is sprayed into a container filled with liquid nitrogen in a spray manner using an atomized nozzle, collected and dried in a vacuum dryer to obtain a precursor powder.

[0047] 3. Calcination and reduction of precursor

[0048] The doped precursor was calcined in an argon atmosphere at 500° C. for 0.5 h. The PVP in the frozen precursor is decomposed and removed to obtain doped tungsten oxide while avoiding the oxidation of zirconium boride. The doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com