Aluminum nitride aluminum-coated base plate and preparation method thereof

A technology of aluminum nitride aluminum-clad substrate and aluminum nitride ceramics, which is applied in the field of ceramic metallization, can solve the problems of poor cold and thermal shock resistance of aluminum nitride copper-clad substrates, achieve good bonding force, improve wettability, and improve The effect of the surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

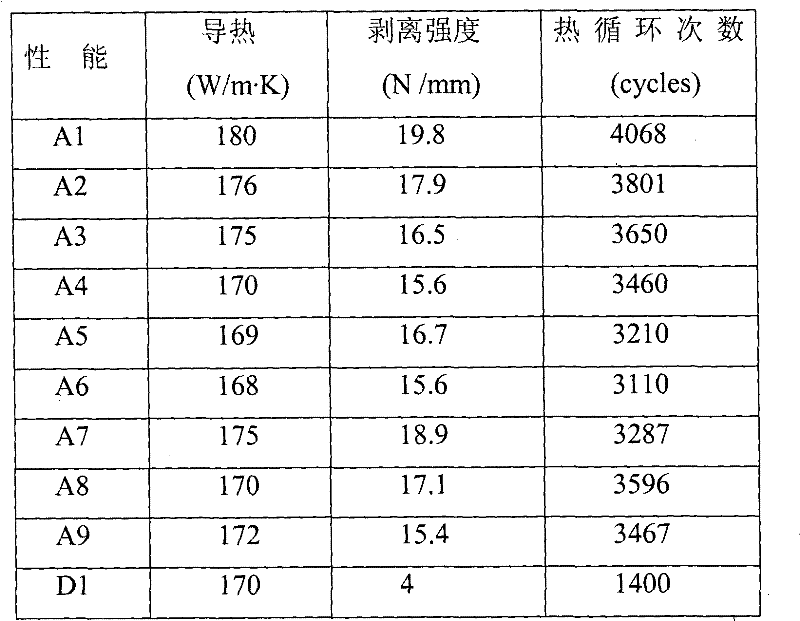

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing an aluminum nitride ceramic copper-clad substrate, comprising the following steps:

[0020] S1. Form a modified base layer containing ceramic powder and sintering aid on the surface of the aluminum nitride ceramic substrate, the ceramic powder is SiO 2 、Al 2 o 3 At least one of them; the sintering aid is Cu powder, Cu 2 At least one of O powder and CuO powder;

[0021] S2. Sintering the aluminum nitride ceramic substrate with the modified base layer at a high temperature in vacuum or in an inert atmosphere to obtain a precursor of an aluminum nitride aluminum-clad substrate containing an oxide modified layer;

[0022] S3. Vacuum brazing the precursor of the aluminum nitride aluminum-clad substrate and the aluminum sheet through the aluminum-silicon alloy welding sheet to prepare the aluminum nitride aluminum-clad substrate.

[0023] The aluminum nitride substrate used in the present invention is an aluminum ...

Embodiment 1

[0040] 1. Preparation of modified base layer

[0041] An aluminum nitride substrate (manufactured by Fujian Huaqing Electronic Material Technology Co., Ltd., with a thickness of 600 μm) of 15 mm×15 mm was taken.

[0042] Place the aluminum nitride substrate in a vacuum ion coating machine (JIL type vacuum coating machine produced by Shenzhen Zhenhengchang), and the vacuum degree is 5*10 -4 Pa, the bias voltage of the bias power supply is 200V, the power of the bias power supply is 1500W, the duty cycle of the bias power supply is 40%, the target material is the above-mentioned ceramic powder and sintering aid, the ceramic powder is alumina, sintered The auxiliary agent is cuprous oxide, 70 parts by weight of aluminum oxide, 30 parts by weight of cuprous oxide, and the ion plating time is 5 minutes. A modified base layer with a thickness of 1.5 μm was obtained.

[0043] 2. Sintering

[0044] Place the aluminum nitride substrate with a modified base layer on the surface for s...

Embodiment 2

[0049] 1. Preparation of modified base layer

[0050] An aluminum nitride substrate (produced by Fujian Huaqing Electronic Material Technology Co., Ltd., with a thickness of 700 μm) of 15 mm×15 mm was taken.

[0051] Place the aluminum nitride substrate in a vacuum ion coating machine (JIL type vacuum coating machine produced by Shenzhen Zhenhengchang), and the vacuum degree is 6*10 -4 Pa, the bias voltage of the bias power supply is 250V, the power of the bias power supply is 1600W, the duty cycle of the bias power supply is 50%, the target material is the above-mentioned ceramic powder and sintering aid, and the ceramic powder is silicon oxide and oxide Aluminum, copper oxide as sintering aid, 30 parts by weight of silicon oxide, 60 parts by weight of aluminum oxide, 10 parts by weight of copper oxide, and ion plating time of 10 minutes. A modified base layer with a thickness of 2 μm was obtained.

[0052] 2. Sintering

[0053] The aluminum nitride base material with modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com