Preparation method of copper-based graphene composite blocky material

A graphene composite and block material technology, applied in the field of copper-based composite materials, can solve the problems of weakening the performance of graphene, achieve good thermal conductivity, good raw material performance, and avoid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the preparation method of copper-based graphene composite block material is as follows:

[0041] (1) Take copper nitrate according to that the copper content is 99.8wt%, and prepare copper nitrate ethanol solution.

[0042] (2) Add graphene in the copper nitrate ethanol solution, the ratio of the mass of graphene to the copper element is 2:998, and ultrasonically stir for 1h; then add the glucose solution with a concentration of 0.6M, and ultrasonically stir for 0.5h; then Add a 0.6M sodium hydroxide solution while ultrasonically stirring to obtain a mixed solution.

[0043] The mixed solution was placed in a reaction kettle, and hydrothermally reduced in an oven at 80°C for 2 hours; the resulting reaction product was filtered, and then washed with a mixed liquid of deionized water and ethanol. The volume ratio of alcohol and deionized water in the mixed liquid was 2 : 1, then dried in vacuum at 60°C to obtain a powder product.

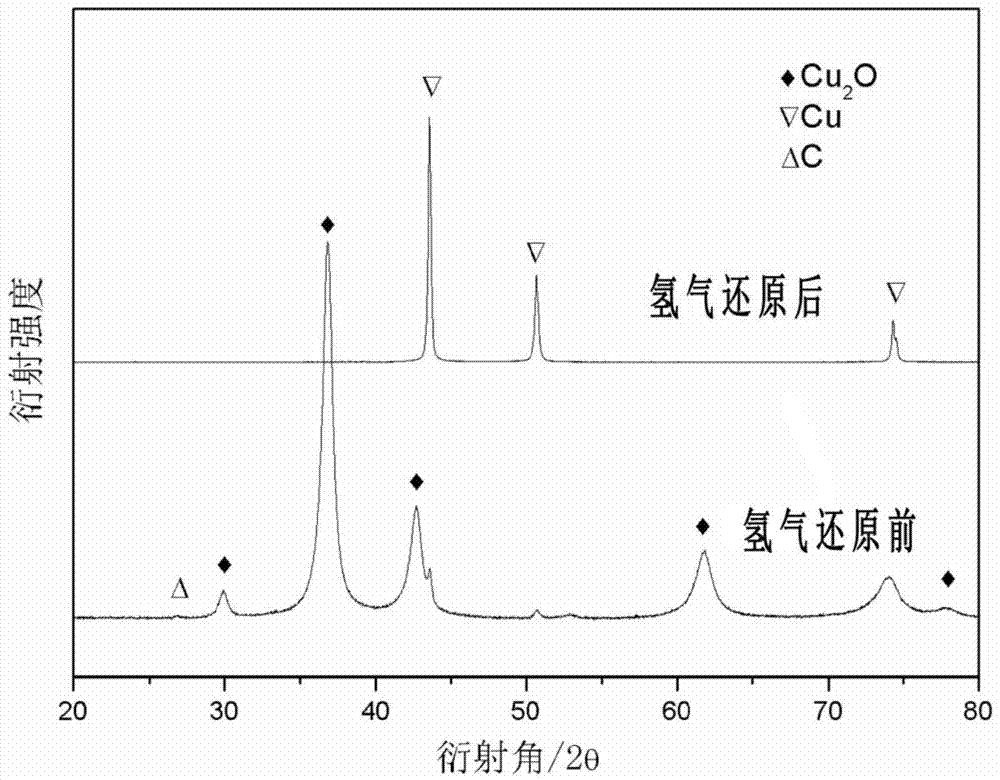

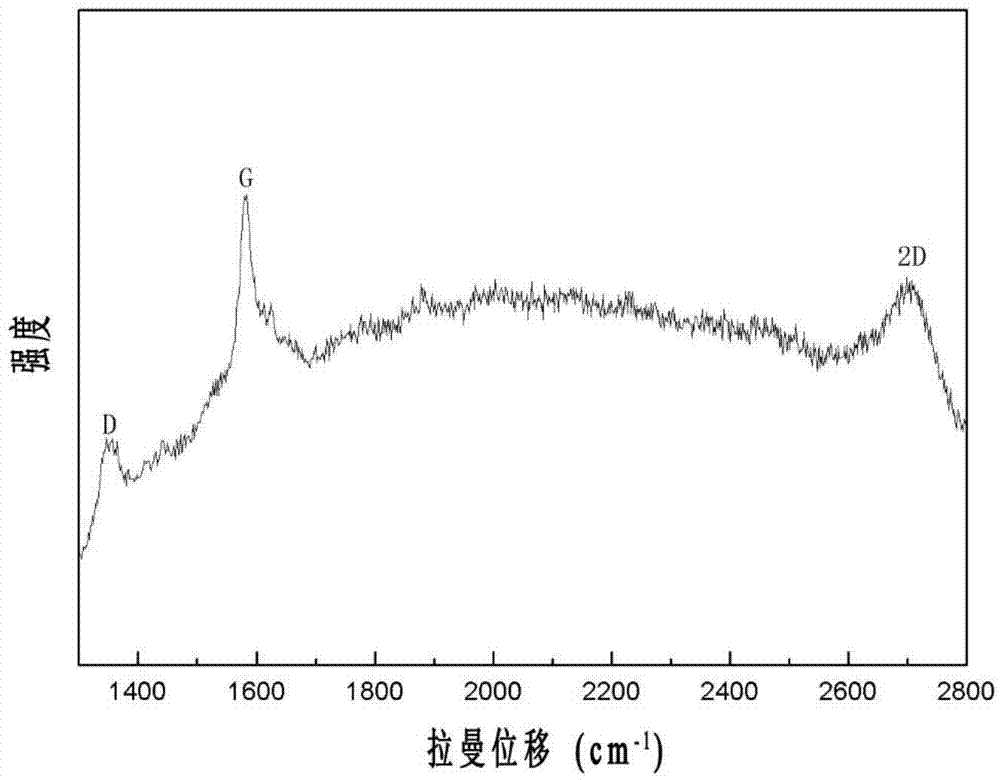

[0044]Carry...

Embodiment 2

[0054] A kind of preparation method of copper-based graphene composite block material is provided in the present embodiment as follows:

[0055] (1) Take copper sulfate according to that the copper content is 99wt%, and prepare copper sulfate ethanol solution.

[0056] (2) Add graphene to the copper sulfate ethanol solution, the ratio of the mass of graphene to the mass of copper element is 1:99, and ultrasonically stir for 2 hours; then add glucose solution with a concentration of 0.5M, and ultrasonically stir for 1 hour; then ultrasonically While stirring, a potassium hydroxide solution with a concentration of 0.5M was added and stirred to obtain a mixed solution.

[0057] Put the mixed solution in a reaction kettle, and hydrothermally reduce it in an oven at 80°C for 4 hours; filter the obtained reaction product, and then wash it with a mixed liquid of deionized water and ethanol. The volume ratio of deionized water and alcohol in the mixed liquid is 1 : 1, then dried in v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com