Ti surface HA active coating biological material and its preparation method

A biomaterial and active coating technology, applied in the field of powder metallurgy, can solve the problems of easy peeling and low bonding strength between the coating and the substrate, and achieve the effect of ensuring no decomposition, reducing voids, and improving the bonding strength of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

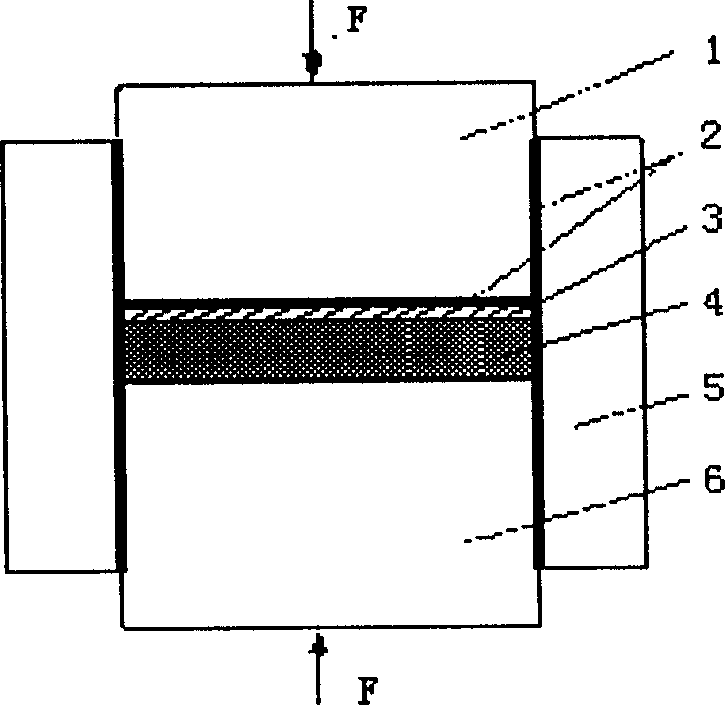

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1. Take 4.8g of HA and 0.1g of water glass into a powder mixer and mix evenly, then bake in an oven at 100°C for 1 hour to obtain passivated HA powder as coating powder ①. Take 5.0g of titanium powder and 0.1g of coating powder into a graphite mold of φ24, install the pressure head and compact it, then put it into the spark plasma sintering equipment (SPS), vacuumize to 4Pa, pressurize to 30MPa, and heat up The speed was 150°C / min, the temperature was raised to 900°C and kept for 2 minutes, and then cooled to room temperature and taken out to obtain the biological material with HA active coating on the Ti surface.

Embodiment 2

[0013] Embodiment 2. Get 5.0g of titanium powder and 1.0.2g of coating powder into the graphite mold of φ24, put on the pressure head and compact it, then put it into SPS, vacuumize to 10Pa, pressurize 20MPa, and the heating rate is 80°C / min, heat up to 850°C for 10min, cool to room temperature and take out to obtain HA active coating biomaterial on Ti surface.

Embodiment 3

[0014] Embodiment 3. Get 4.0g of HA, 0.7g of titanium powder and 0.3g of water glass and put them into a powder mixer and mix them evenly, then bake in an oven at 100°C for 1 hour to obtain passivated HA mixed powder, as a coating Layer powder ②. Take respectively 5.0g of titanium powder and 0.1g of coating powder into a φ24 graphite mold, install the pressure head for compaction, then put it into the SPS, vacuumize to 6Pa, pressurize at 25MPa, and heat up at a rate of 150℃ / min , heated to 950° C. for 6 minutes, cooled to room temperature, and taken out to obtain a biomaterial with HA active coating on the Ti surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com