Sensor circuit board support

A technology of circuit boards and sensors, which is applied in the direction of instruments, liquid level indicators, machines/engines, etc., can solve the requirement of reducing the internal installation space of the whole machine, reduce design, production, component costs, difficulty of disassembly and assembly, and later maintenance Difficulty and other problems, to achieve the effect of reducing space requirements, reducing disassembly and assembly time, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

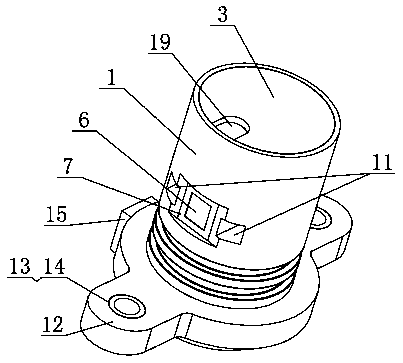

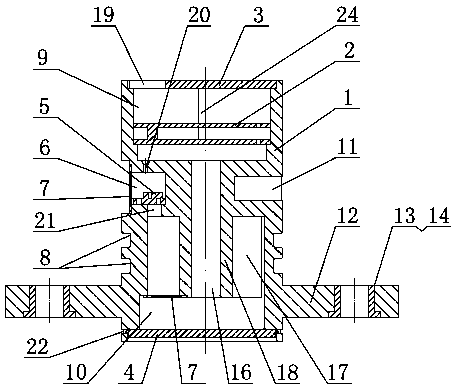

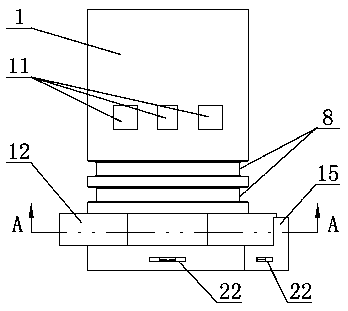

[0038] Such as figure 1 As shown, the bracket body 1 of the present invention is integrally injection molded, and its main body is cylindrical, such as figure 2 As shown, the center of the upper and lower ends of the bracket body 1 is respectively provided with a first counterbore 9 and a second counterbore 10 in the axial direction, and the first counterbore 9 and the second counterbore 10 are cylindrical stepped holes; The inner diameters of the stepped holes of the hole 9 decrease sequentially from the outside to the inside, and the stepped holes of the first counterbore 9 are sequentially inserted with the circuit board 2 and the upper cover 3 from the inside to the outside, and the circuit board 2 and the upper cover 3 pass through the sealant Bonding and fixing, the inner wall surface of the first counterbore 9 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com