Device for preventing high temperature caused by welding metal embedded part from burning out concrete base layer and method thereof

A technology of concrete base and metal embedded parts, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of brittle welds, reduce welding quality, reduce project progress, etc., so as to achieve welding quality without reducing, The effect of not degrading the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

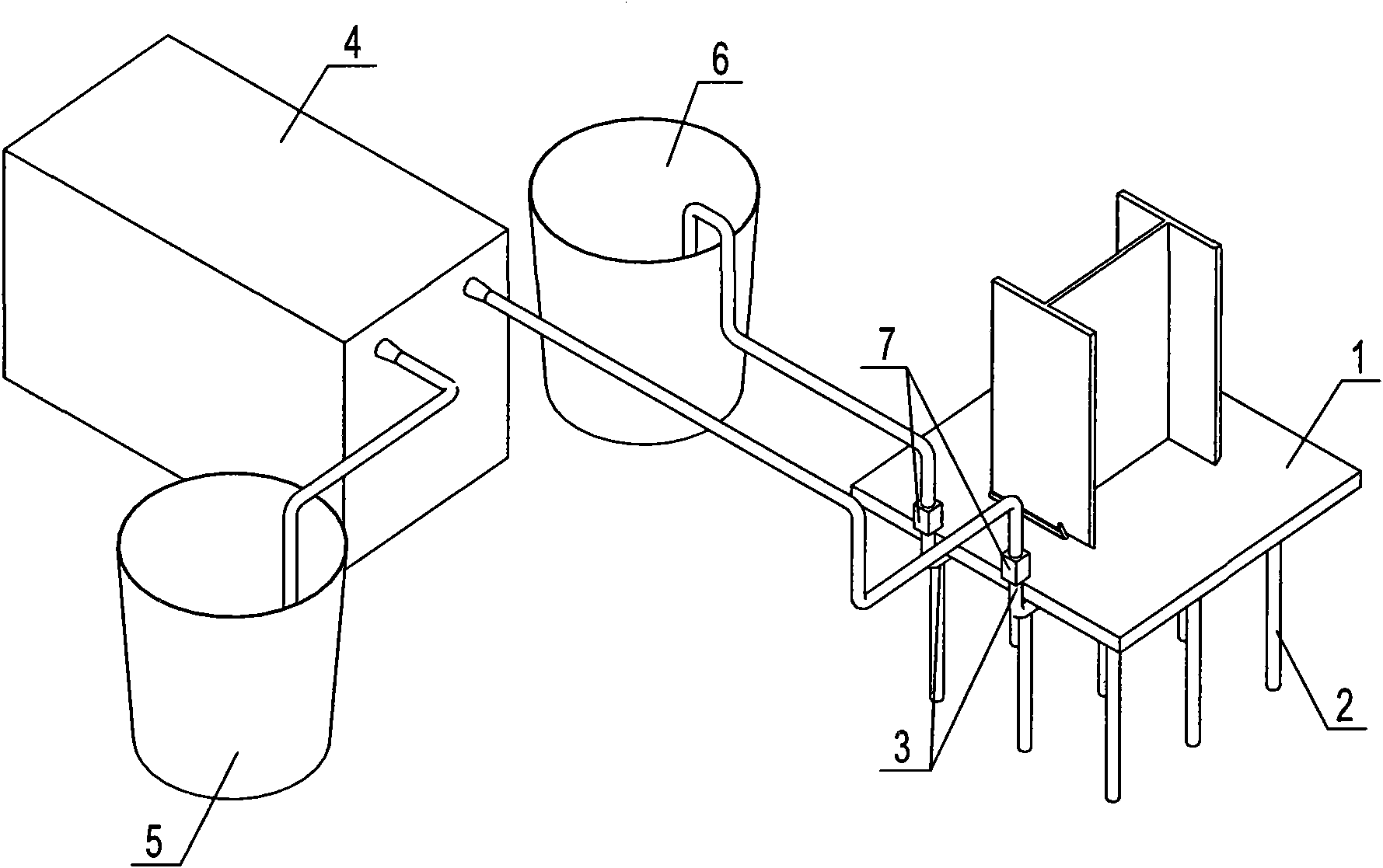

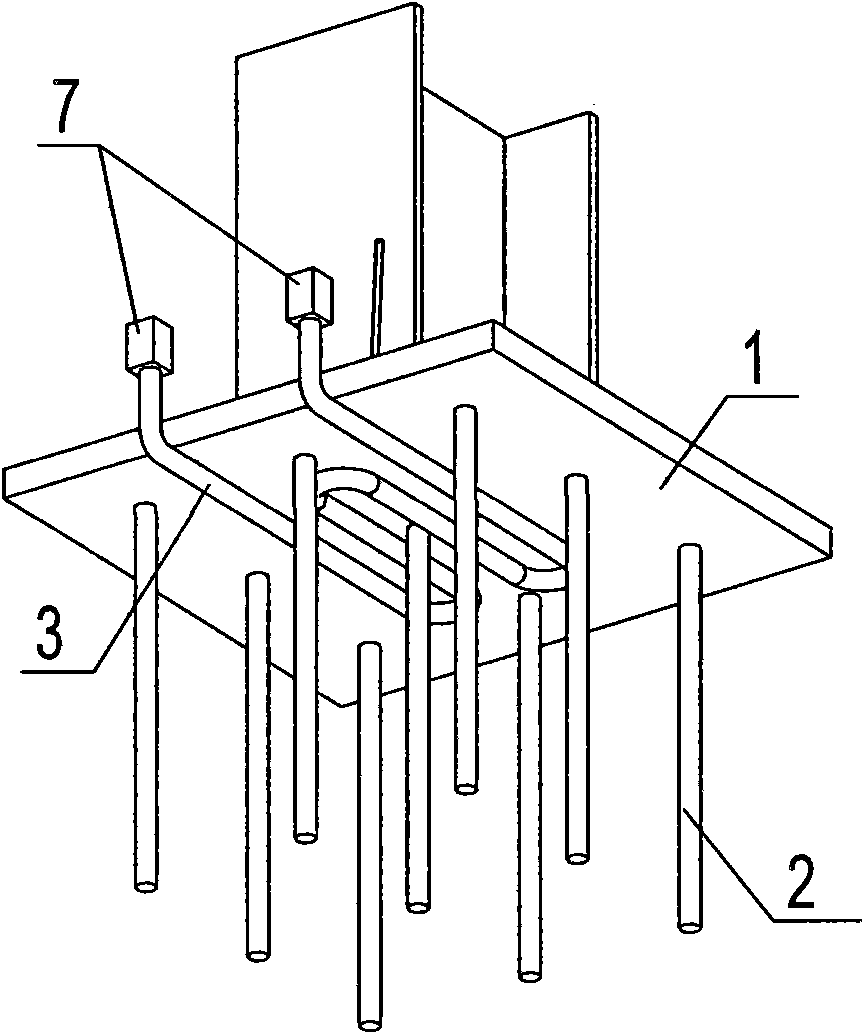

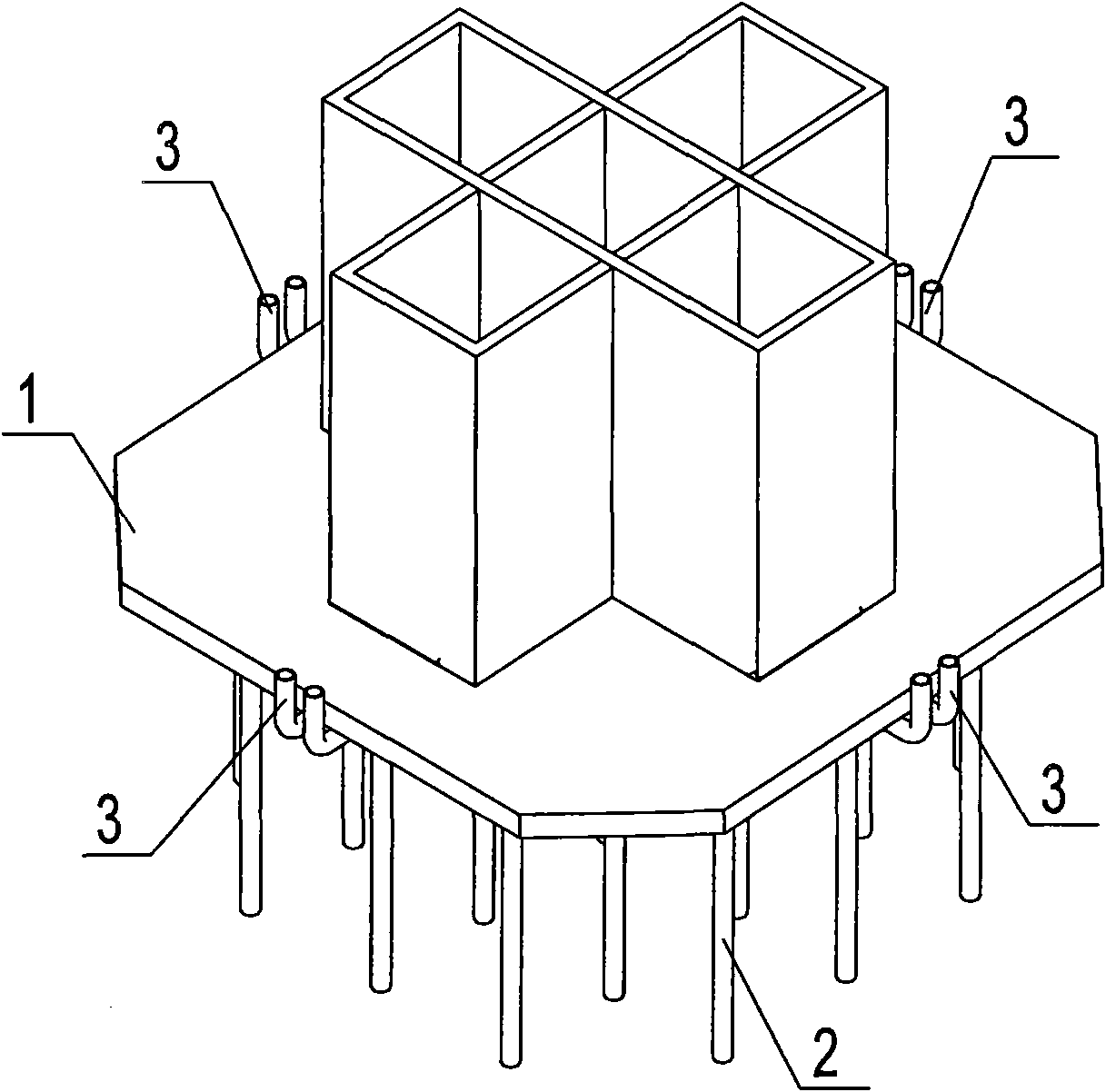

[0030] Such as figure 1 , 2 As shown, a metal embedded part fixed on the concrete includes a pre-embedded slab 1 and a pre-embedded reinforcement 2; The plate 1 forms an embedded part and is a whole. The device for preventing the metal embedded parts from being welded to high temperature and burning the concrete base includes a metal pipe 3 , a water pump 4 , a water supply container 5 , a drainage container 6 and a water pipe connector 7 . The metal pipe 3 is welded on the pre-embedded plate 1, the water supply container 5 is connected to the water pump 4 through the water pipe, the water outlet of the water pump 4 is connected to one end of the metal pipe 3 through the water pipe connector 7, and the other end of the metal pipe 3 is connected through the water pipe connector 7 is connected to the drain container 6. The metal pipe 3 is a hollow pipe (such as a steel pipe) that can circulate water and can be poured into cement mortar, with a diameter of preferably 15mm to 2...

Embodiment 2

[0033] The device for avoiding the welding of metal embedded parts to burn out the concrete base at high temperature saves the water pump 4, the water supply container 5 and the drainage container 6, the water supply is directly supplied by tap water, and the drainage is directly discharged into the sewage pipe; the metal pipe is a steel pipe; others are the same as in the embodiment 1.

Embodiment 3

[0035] The thickness of the components to be welded above the embedded plate 1 is relatively large, and the input heat of welding is relatively concentrated. At this time, the high-power water pump 4 can be selected in this embodiment to speed up the water flow in the metal pipe 3 and enhance the cooling effect. The metal pipe is a copper pipe. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com