Linkable double hoisting mechanism and speed regulation method of tower crane

A technology of tower cranes and hoisting mechanisms, applied in cranes, clockwork mechanisms, hoisting devices, etc., can solve problems such as high cost, failure to reach project height, large impact, etc., and achieve satisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

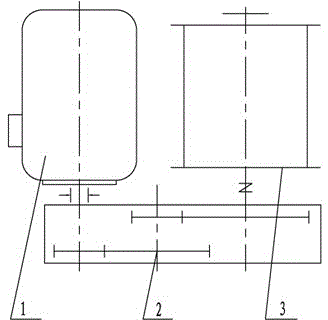

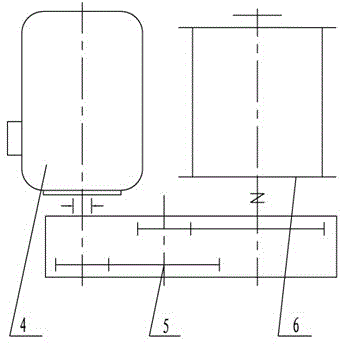

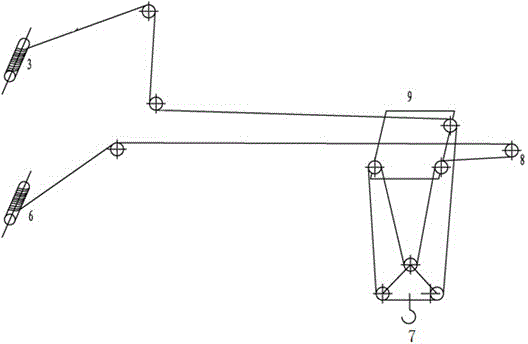

[0027] The first set of hoisting structure includes single-speed motor 1, reducer I2 and drum I3; the other set of hoisting structure includes two-speed motor 4, reducer II5 and drum II6, drum I3 is connected to one end of wire rope 9, and The wire rope is connected to the reel II6 after passing around the steering pulley 8, the trolley and the hook 7 at the arm end of the hoisting mechanism. The two ends of the hoisting wire rope are rooted in two drums respectively. The wire rope goes around the transition pulleys, the turning pulleys at the arm end, the load trolley and the hook to achieve double or quadruple rope winding (the figure shows the four-fold rope winding method) .

[0028] Since the wire rope can go around two drums, the rope capacity is L 1 +L 2 , Which meets the length of the steel wire rope required for high-rise construction, and the maximum lifting weight can be met if the four-fold rope winding is used.

[0029] Two mechanism motors are controlled by electrica...

Embodiment 2

[0031] When both motor I1 and motor II4 are single-speed motors, the speed of motor I is V 1 , The speed of motor II is V 2 , Get four speeds through combination, namely motor I moves, motor II does not move, get speed V 1 ; Motor I does not move, motor II moves, get the speed V 2 ; Motor I, motor II reverse direction, get speed V 1 +V 2 ; Motor I moves, motor II rotates the same, get speed V 1 -V 2 ;

Embodiment 3

[0033] When motor I is a two-speed motor and motor II is a two-speed motor, the speed of motor I is V 1 , V 2 , The speed of motor II is V 3 , V 4 , Through the combination to get 12 speeds, that is, motor I moves, motor II does not move, get speed V 1 , V 2 ; Motor I does not move, motor II moves, get the speed V 3 , V 4 ; Motor I, motor II reverse direction, get speed V 1 +V 3 , V 1 +V 4 , V 2 +V 3 , V 2 +V 4 ; Motor I moves, motor II rotates the same, get speed V 1 -V 3 , V 1 -V 4 , V 2 -V 3 , V 2 -V 4 .

[0034] The invention uses two most common lifting mechanisms to realize multiple lifting speeds with the least cost, and meets the requirements of large and medium-sized tower cranes for lifting speed and rope capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com