Flat spiral heat exchange tube and its on-line tube processing technology

A technology of spiral heat exchange tube and processing technology, applied in the field of metal tube processing, can solve the problem that the heat exchange area and the heat exchange efficiency are difficult to be greatly improved, the cold working process is difficult to ensure the quality of the finished product, and the finished product specification and length of the heat exchange tube are limited. problem, to achieve the effect of improving heat exchange efficiency, low cost and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

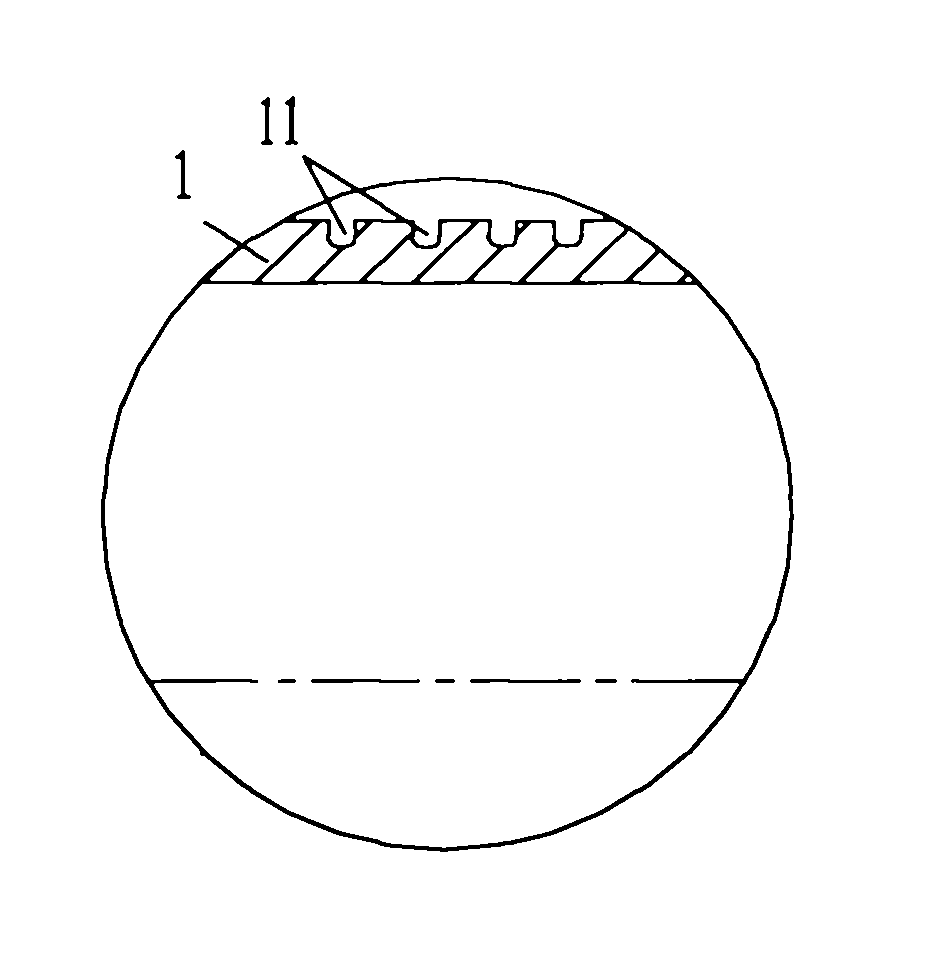

[0055] Such as Figure 5 As shown, the flat spiral heat exchange tube 1 of the present invention is a metal welded pipe with a certain length, such as austenitic stainless steel welded pipe, carbon steel welded pipe, titanium and titanium alloy welded pipe, nickel and nickel alloy welded pipe, or austenitic - Ferritic duplex steel welded pipes, etc.

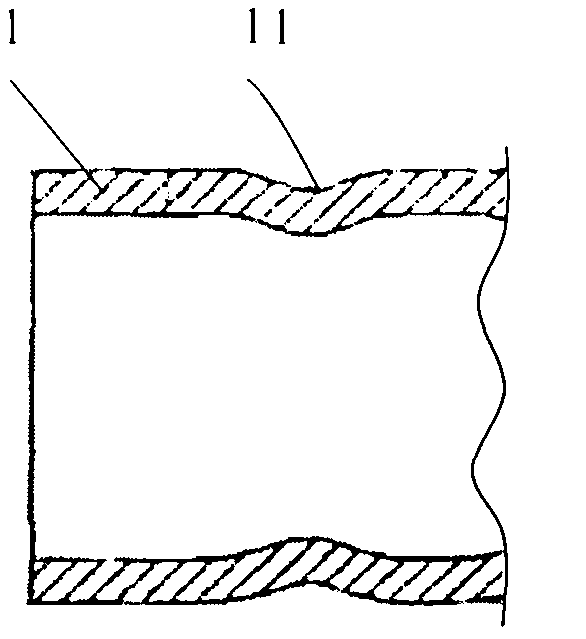

[0056] Figure 5 Its cross-sectional shape is shown, Image 6 Shown is the helical shape of its outer surface. The inner surface of the pipe body 2 is a smooth surface formed by connecting two parallel surfaces and two arc transition surfaces.

[0057] The inside of the pipe body 2 forms a medium channel 3 through which the heat exchange medium flows.

[0058] The tube body 2 has a flat cross section, and divides the medium channel 3 into two side heat exchange areas 31 and a middle heat exchange area 32 . The cross-sectional areas of the two side heat exchange areas 31 are approximately the same as the cross-sectional areas...

Embodiment 2

[0067] The structure of the flat spiral heat exchange tube of this embodiment is basically the same as that of the above embodiments, both including a tube body, the difference is that in this embodiment, there are straight tube sections at both ends of the tube body. The straight pipe section and the flat spiral section should transition smoothly without sharp deformation.

[0068] The flat spiral heat exchange tube with the straight pipe section has better assembly and sealing performance in the assembly and processing of heat exchange equipment.

Embodiment 3

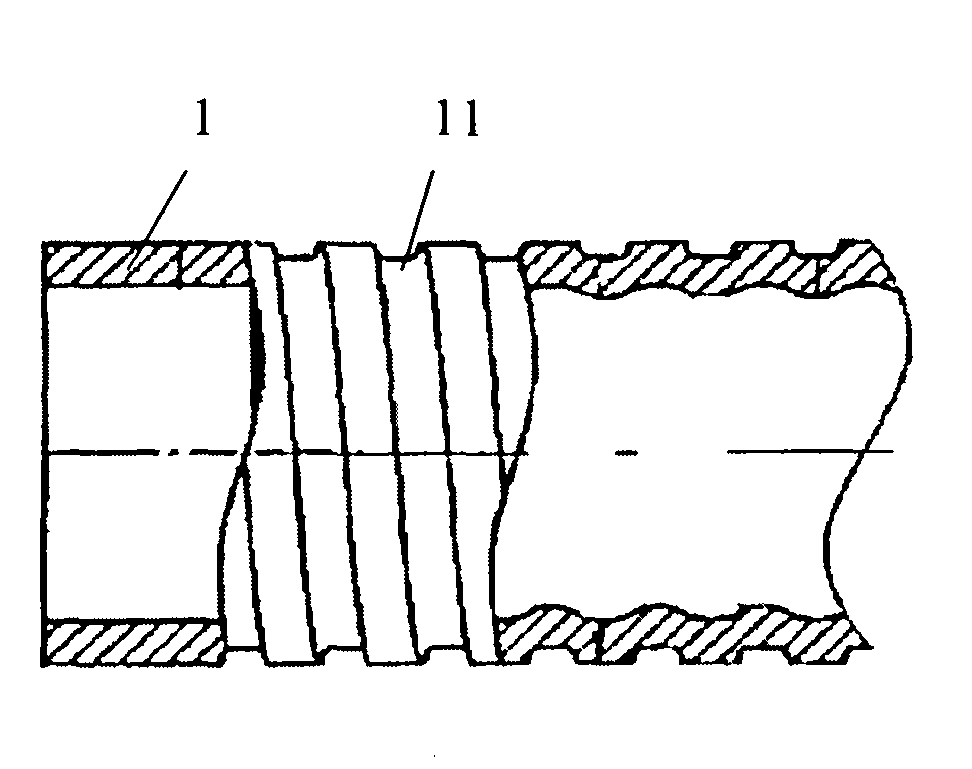

[0070] The online tube-making process of the flat spiral heat exchange tube 1 of the present invention at least includes:

[0071] Step 1, obtaining the tube body 2 .

[0072] In this embodiment, the pipe body 2 is a metal welded pipe, and its cross section is formed by connecting two parallel surfaces and two arc transition surfaces. combine Figure 7 As shown, the pipe body 2 is obtained through a pressing process.

[0073] The pressing equipment mainly includes a series of brackets 401, 402, 403, each bracket is respectively provided with upper rollers 411, 412, 413 and lower rollers 421, 422, 423, and a series of left rollers are respectively arranged on both sides of the pipe body 2. Roller, right roller (not shown in the figure). A series of gradually deformed flat stampers are arranged or formed on each roller, and these flat stampers all have rotating lines.

[0074] The flat spiral tube body 2 is obtained by stepwise deformation through four-side extrusion.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com