Solid waste incineration kiln

A technology for incinerating kilns and kiln bodies, which is applied in the direction of incinerators, combustion methods, combustion types, etc., and can solve problems such as damage to equipment, shutdown, coking, etc., and achieve the effects of wide adaptability, not easy to coke, and easy to burn through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

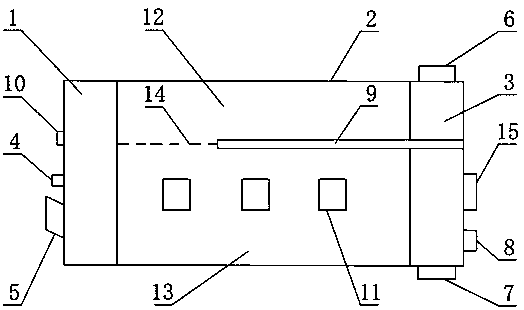

[0014] Such as figure 1 As shown, a solid waste incineration kiln includes a kiln body and a drive motor. The kiln body is composed of a kiln tail 1, a cylinder body 2 and a kiln head 3. The cylinder body 2 is inclined along its axial direction, and the kiln tail 1 is provided with a feed port 5 and an ignition port 4, the kiln head 3 is provided with a slag outlet 7, a flue gas outlet 6 and an air inlet 8, and the drive motor is provided with a limiter so that the kiln body can be semi-rotary. sports. The bottom surface of the inner wall of the kiln is plane.

[0015] The kiln body is provided with a separation heat storage plate 9 to separate the kiln body into upper and lower two combustion chambers, wherein the upper part is a secondary combustion chamber 12, and the lower part is a main combustion chamber 13. The separation heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com