Aluminum film baffle device and pulse solid engine applying same

A pulsed solid and engine technology, applied in the direction of machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of solid rocket motors with relatively large overall design restrictions, fragments that are not easily ablated, and engine thrust loss. To achieve the effect of stable and reliable working performance, compact structure, cheap and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

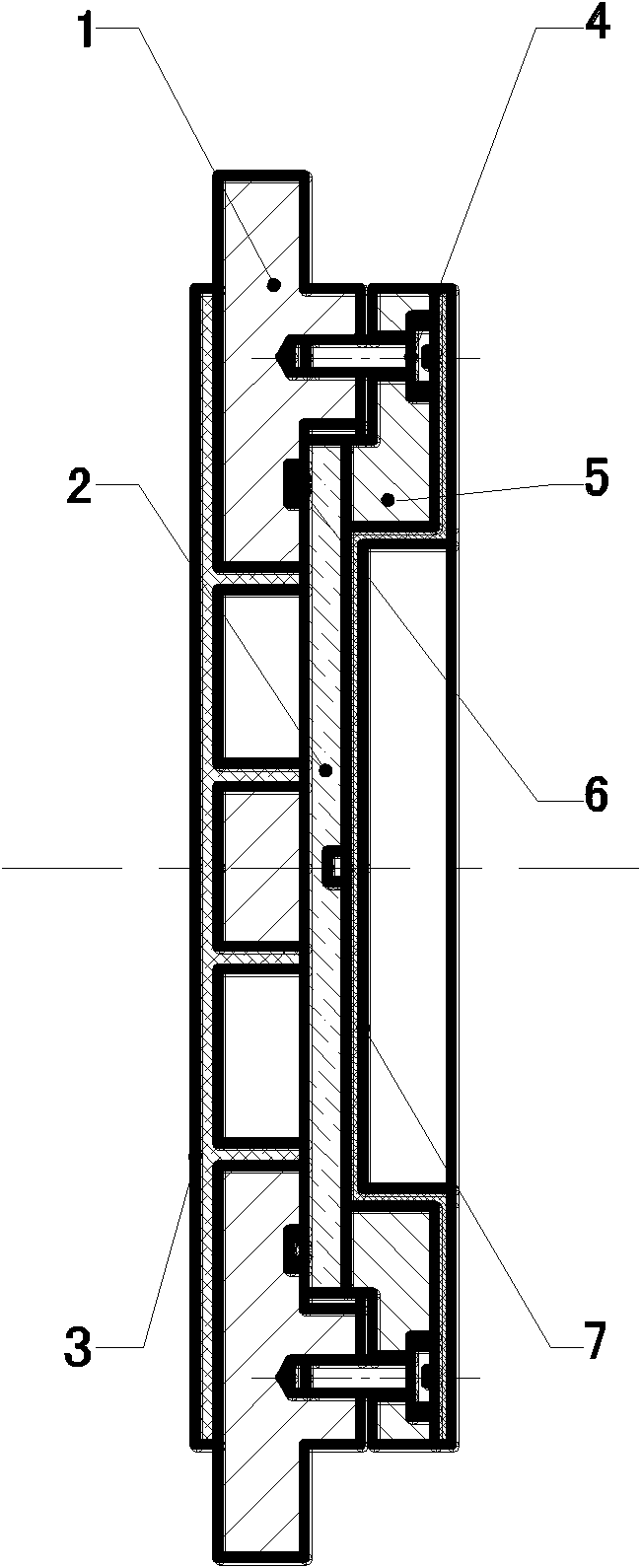

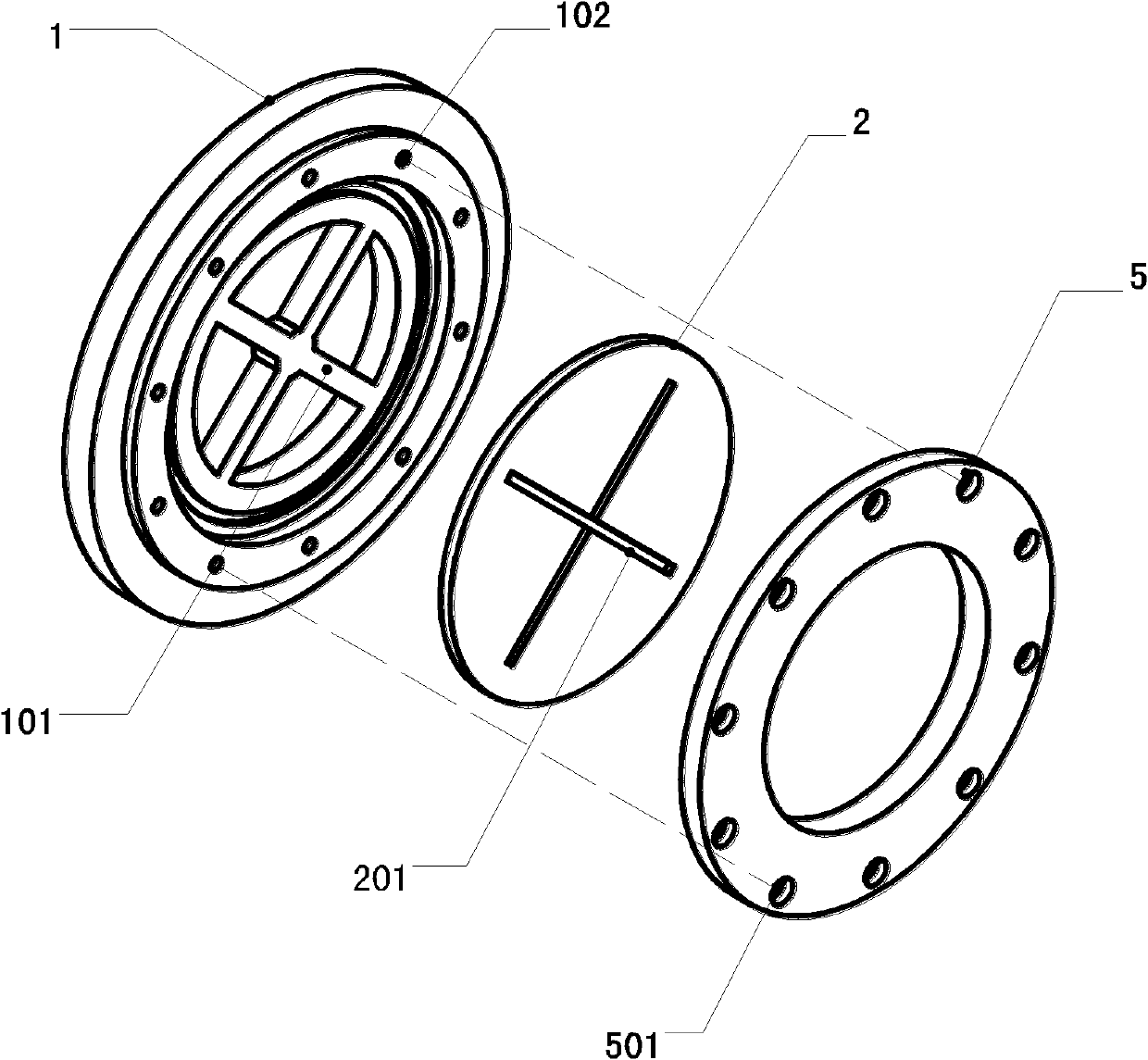

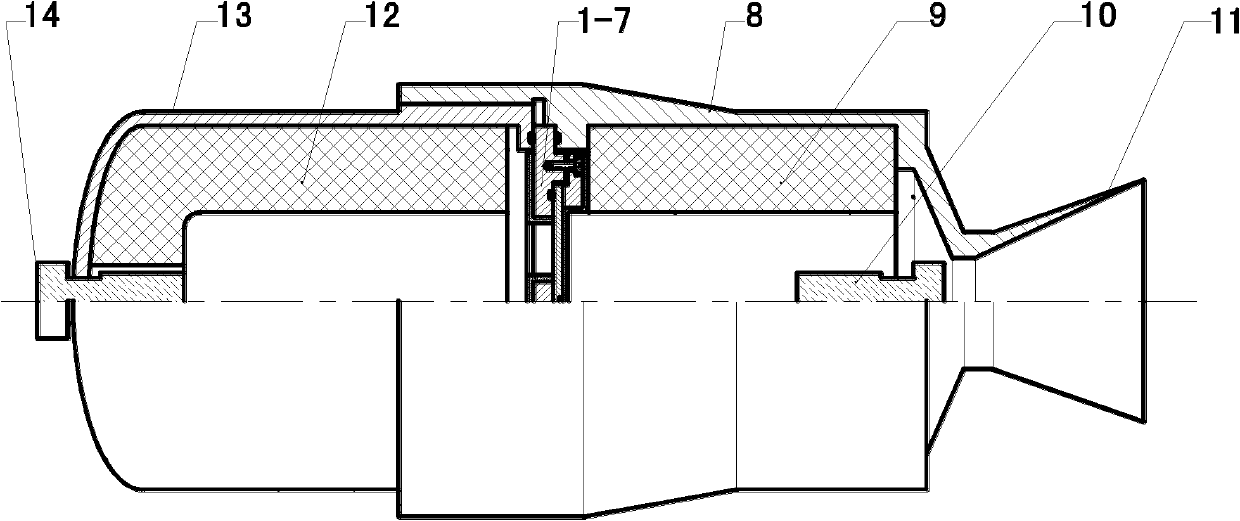

[0025] The impulsive solid engine using the aluminum diaphragm device generally packs two stages of independent solid propellant grains one after the other in the combustion chamber, and the two stages of grains share the same nozzle. The aluminum membrane partition device is located between the two-stage grain columns, separating the two-stage grain columns. When the pulse solid motor is working, the first-stage grain is first ignited to work, and the aluminum membrane partition device will not break at this time, separating the second-stage grain from the high-temperature gas; then the second-stage grain is ignited to work, and then At that time, the aluminum film partition device is broken, so that the second pulse grain can work normally. The rupture time of the aluminum diaphragm device can be flexibly controlled according to the needs of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com