Microwave high-temperature continuous tunnel kiln

A tunnel kiln and high temperature technology, applied in the field of microwave high temperature heating equipment, can solve the problems that the tunnel kiln cannot realize continuous circulation and non-stop work, cannot use the built-in insulation structure, and the purity of the insulation layer refractory material is high, so as to improve the utilization of microwave efficiency, improve service life, and reduce burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

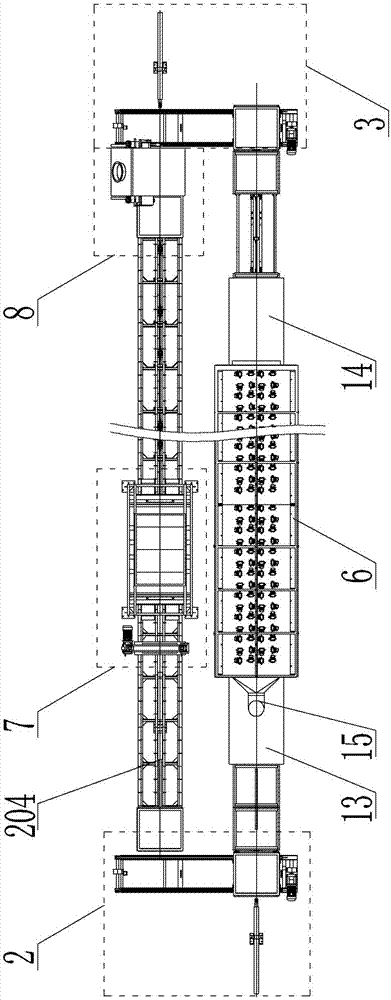

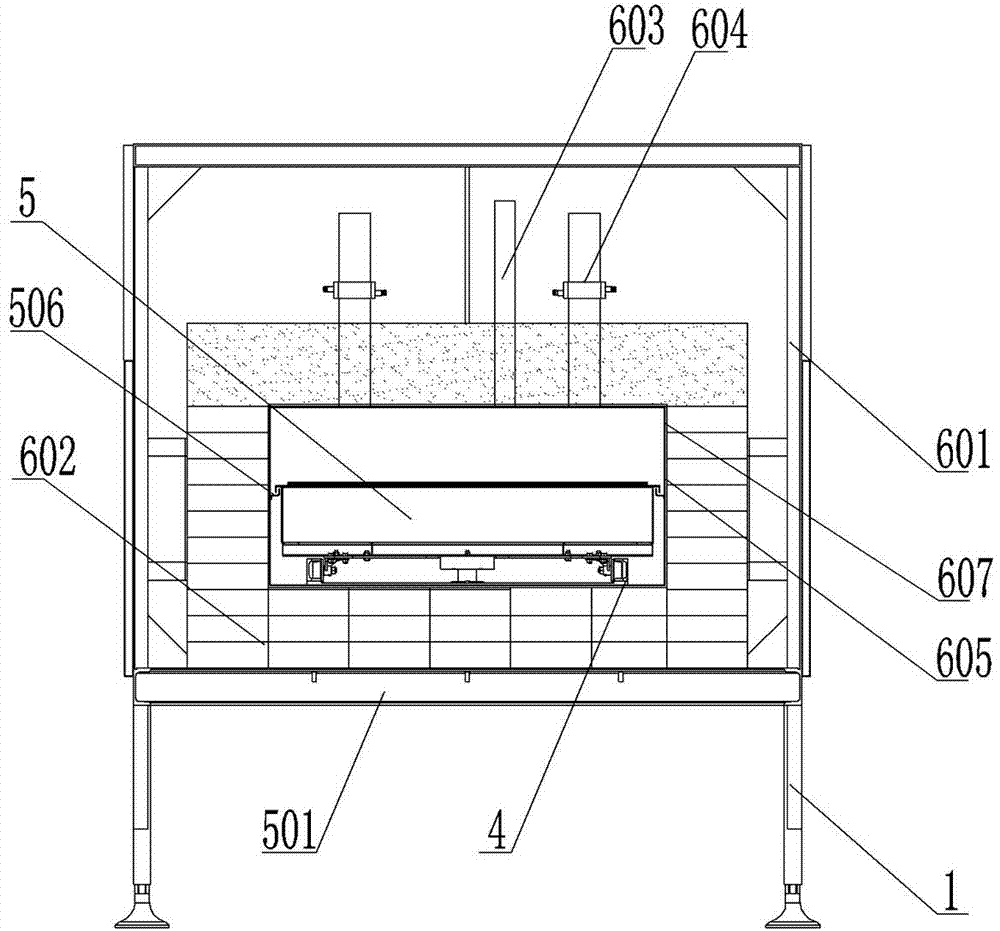

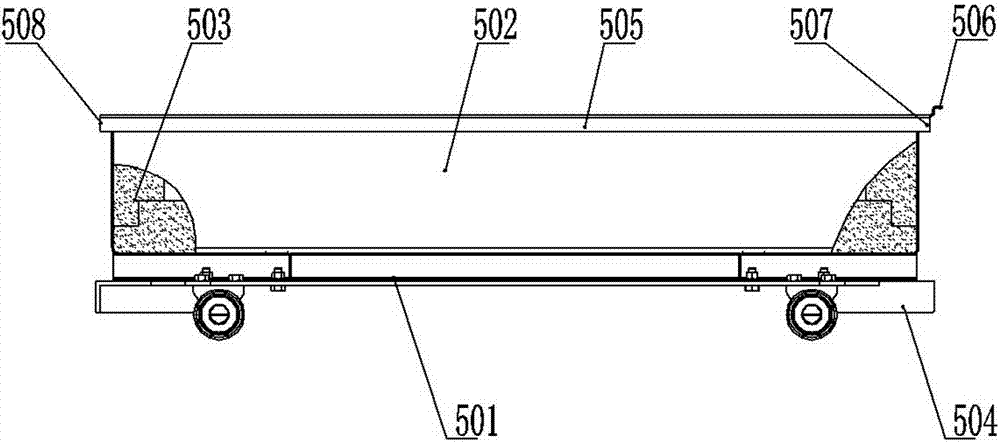

[0041] see Figure 1-15 , a microwave high-temperature continuous circulation tunnel kiln, comprising two mutually parallel supports 1, an inlet end redirection device 2 and an outlet end redirection device 3 respectively arranged at both ends of the support 1, and a kiln car arranged on the support 1 Walking guide rail 4, kiln car 5, tunnel kiln body 6 arranged on one of the supports 1, feeding device 7 and unloading device 8 arranged on the other support, and the two ends of the tunnel kiln body 6 The feed inlet suppressor 13 and the discharge outlet suppressor 14, the tunnel kiln kiln body 6 includes a shell 601, an insulation layer 602 arranged inside the casing 601, and a microwave resonator set on the inner wall of the insulation layer 602 The cavity 607 , as well as the temperature measuring device 603 and the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com