At the same time, when the main motor is working, even if the regulator is not required to work, the transmission shaft and plane bearing of the regulator will rotate with the main

motor shaft at high speed, that is, to do useless work, resulting in long-term wear of the plane bearing, resulting in the trouble and trouble of frequently replacing the plane bearing. waste;

[0004] 2. The phenomenon of oil throwing is prominent: when the main motor and the main water pump are working, the

drive shaft and plane bearing of the regulator will rotate at high speed with the main motor shaft, so the

drive shaft and plane bearing will run at high temperature for a long time, causing the lubricating oil to liquefy or even vaporize , causing the regulator to throw oil prominently:

[0005] 3. The plane bearing is damaged when the water pump lifts the shaft and accelerates: the self-weight load of the regulator is borne by the main motor shell. When the water pump starts to lift the shaft, the

impact force on the pump axis is easy to damage the motor base

assembly or the mirror plate of the main motor, and it is easy to damage the regulator. Plane bearing; 4. It is impossible to implement

remote display and

remote control, let alone automatic adjustment of pump blade angle;

[0006] 2. Built-in rotary blade angle mechanical regulator: Although the existing built-in rotary blade angle mechanical regulator has solved the above four problems of the "external fixed blade angle mechanical regulator", it is limited by the

diameter of the outlet. For large water pump blades over 2800mm, the huge adjustment force is not commensurate with the mechanical properties of the regulator. This kind of regulator is only suitable for supporting use on medium and small water pumps. It is really necessary to rely on the adjustment of hydraulic devices to use it on large water pumps. device;

The vane angle detected by the displacement sensor, that is, the actual operating vane angle of the water pump, changes with the movement of the regulator

piston in the cylinder. If the hydraulic oil leaks, the position of the

piston in the cylinder will be changed, resulting in a "collapsing angle". phenomenon occurs

② Although the wear of the sensor contact does not cause the change of the vane angle in the actual operation of the pump, the vane angle value displayed by the control display

system will change with the wear of the sensor contact, so that the displayed vane angle value is consistent with the actual operation of the pump. Inconsistent, this also caused the phenomenon of "collapsing angle";

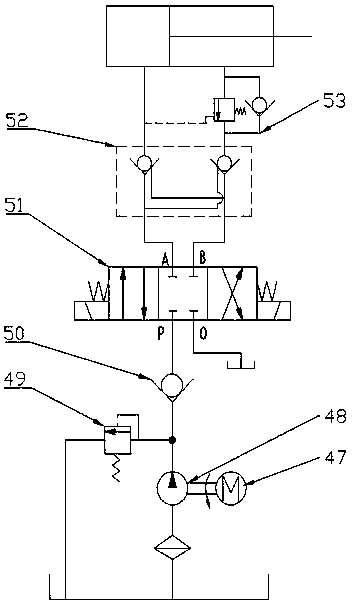

[0009] 2. "Shipping oil": First, the small motor of the regulator,

oil pump, electromagnetic

reversing valve, one-way

hydraulic control valve, etc. are all installed and fixed at the bottom of the

fuel tank. The inlet hole is prone to

chemical reaction between the wire rubber sleeve and the oil and sealing material, resulting in

porosity, which causes the

fuel tank to throw oil; the second is the leakage of the

piston rod in the cylinder through the wall of the cylinder and the top of the piston for the sensor to detect the displacement. The extension rod passes through the two leakage points at the cylinder wall to throw oil;

[0010] 3. It is easy to burn the power supply

slip ring: because the power supply

slip ring is an

open type slip ring, it is easy to burn the slip ring due to the accumulation of dust between the carbon

brush and the slip ring; Scratches on the contact surface of the slip ring are more likely to generate arcs and cause the slip ring to burn;

[0011] 4. The sensor contacts are easily damaged or worn: the displacement sensor is installed on the housing of the regulator in a static state, and the detected object is in a high-speed rotating state with the main motor shaft for a long time, resulting in long-term wear of the sensor contacts. The sensor probe rod needs to be replaced;

[0012] 5. Unsightly: the displacement sensor and the blade angle mechanical

display device are installed on the top of the regulator outer casing, which seriously affects the aesthetics of the regulator and even the overall aesthetic effect of the pump unit;

[0013] 6. The angle of the pump blades cannot be adjusted automatically: the

current regulator can only adjust the angle of the pump blades manually or by clicking the button with the mouse on the computer screen according to the readings of the

ammeter or power meter on the

operating table of the pump

station or the power distribution panel. The

fully automatic adjustment of the pump blade angle is not implemented, which seriously affects the benefits of the fully regulated water pump

Login to View More

Login to View More  Login to View More

Login to View More