Frequency-conversion hand-rubbing motor reducing clutch device and washing machine

A clutch device and washing machine technology, applied in the field of washing machines, can solve the problems of slow sliding down of the clutch shaft sleeve, blockage of the clutch sleeve, slow sliding speed of the shift fork, etc., to speed up the speed of separation and approach, and speed up the up and down sliding The effect of speed and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

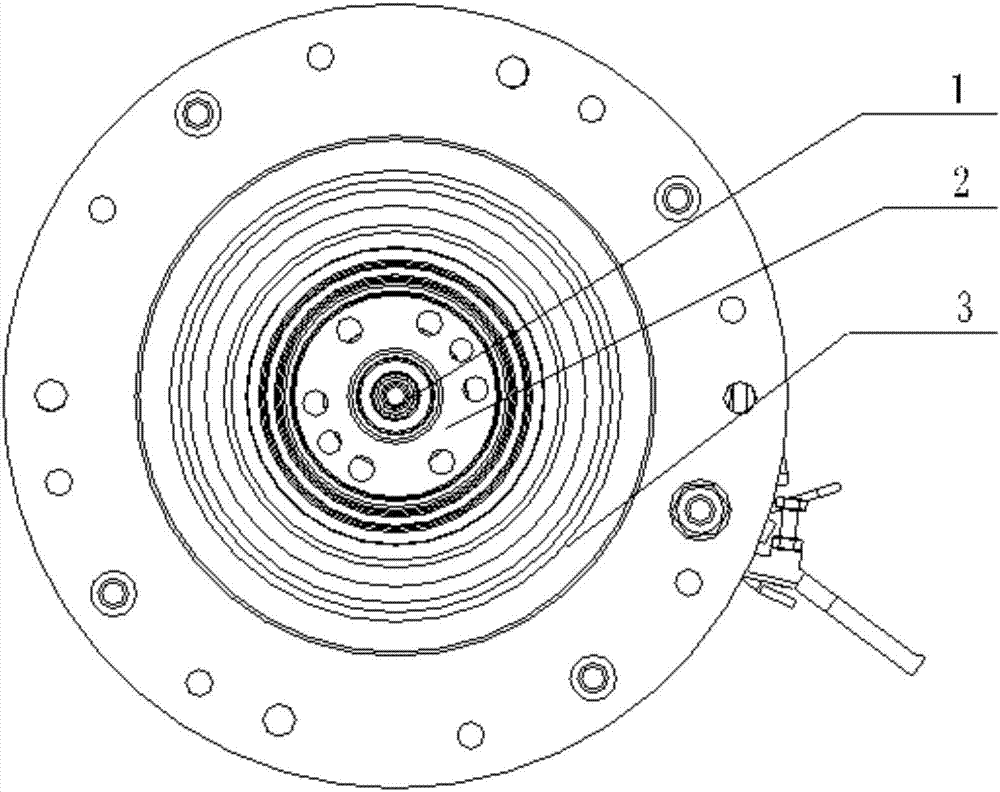

[0046] Such as Figure 1-21 As shown, in this embodiment, the input shaft 22 is sleeved with a torque bushing 13, the torque bushing 13 cannot rotate axially relative to the input shaft 22, and the torque bushing 13 and the clutch bushing 12 To realize the connection between the clutch bushing 12 and the rotor 11, the lower part of the torque bushing 13 is connected with the rotor 11. Preferably, a first damping pad 20 is provided between the lower part of the torque bushing 13 and the rotor 11 , to reduce the noise generated by the rotor 11 during rotation and the impact on the reduction clutch device.

[0047] The inner wall of the torque bushing 13 is provided with a first internal spline 23 to realize the meshing connection between the torque bushing 13 and the input shaft 22, so that the torque bushing 13 rotates with the rotation of the input shaft 22, and the rotation The top of the torque shaft sleeve 13 is provided with a first external spline 32, and the bottom of t...

Embodiment 2

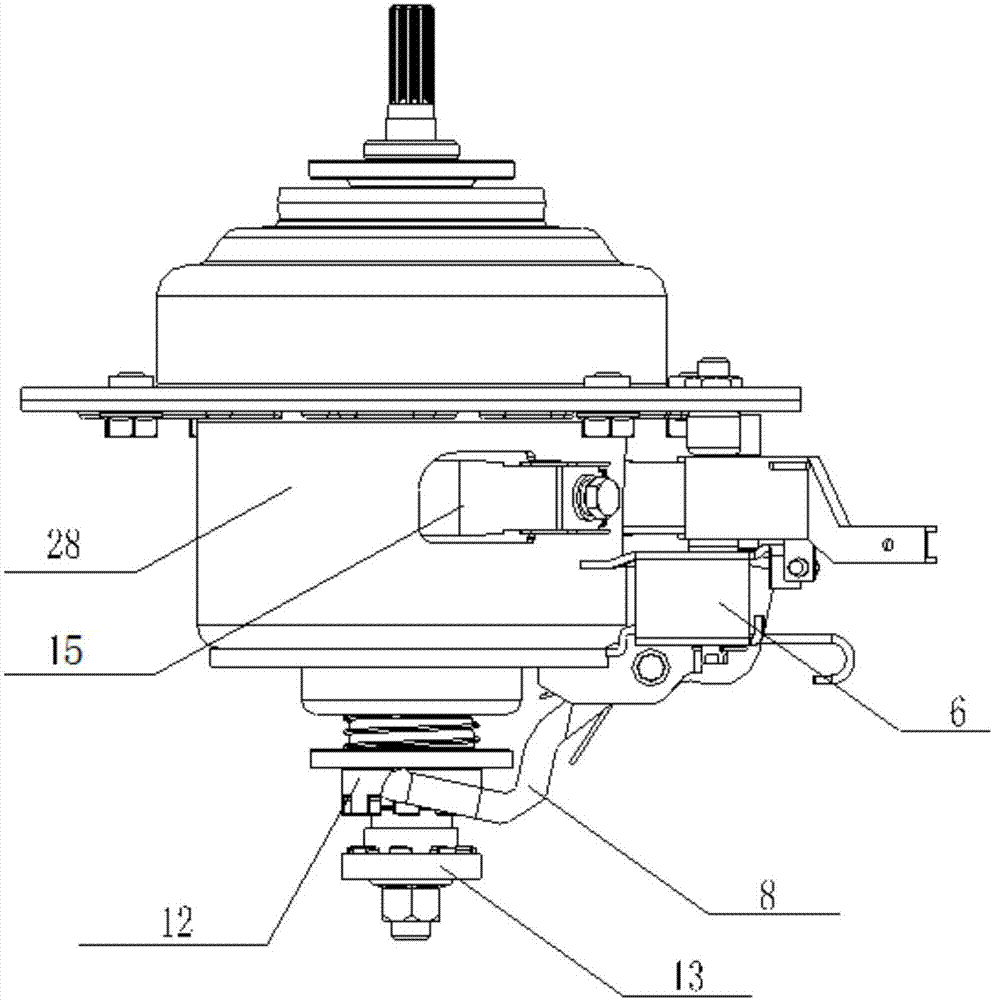

[0050] Such as Figure 1-21 As shown, in this embodiment, the top of the clutch shaft sleeve 12 is provided with a housing 28 composed of the upper end shell 3 and the lower end shell 4, and the clutch shaft sleeve 12 is sleeved with an elastically expandable clutch spring 19, the clutch spring The lower part of the clutch spring 19 is connected with the positioning protrusion 27, and the upper part of the clutch spring 19 is connected with the housing 28, so as to provide a downward sliding force to the clutch bushing 12.

[0051] The stator 10 is installed on the lower end shell 4 .

[0052] The housing 28 is provided with a fixed bracket 7, and the middle part of the shift fork 8 is connected with the fixed bracket 7 through a pin shaft 24. One end thereof is used for contacting with the positioning protrusion 27, and the other end is used for connecting with the pressing rod arranged on the housing 8. 6 are in contact with each other, and the pressing rod 6 is controlled ...

Embodiment 3

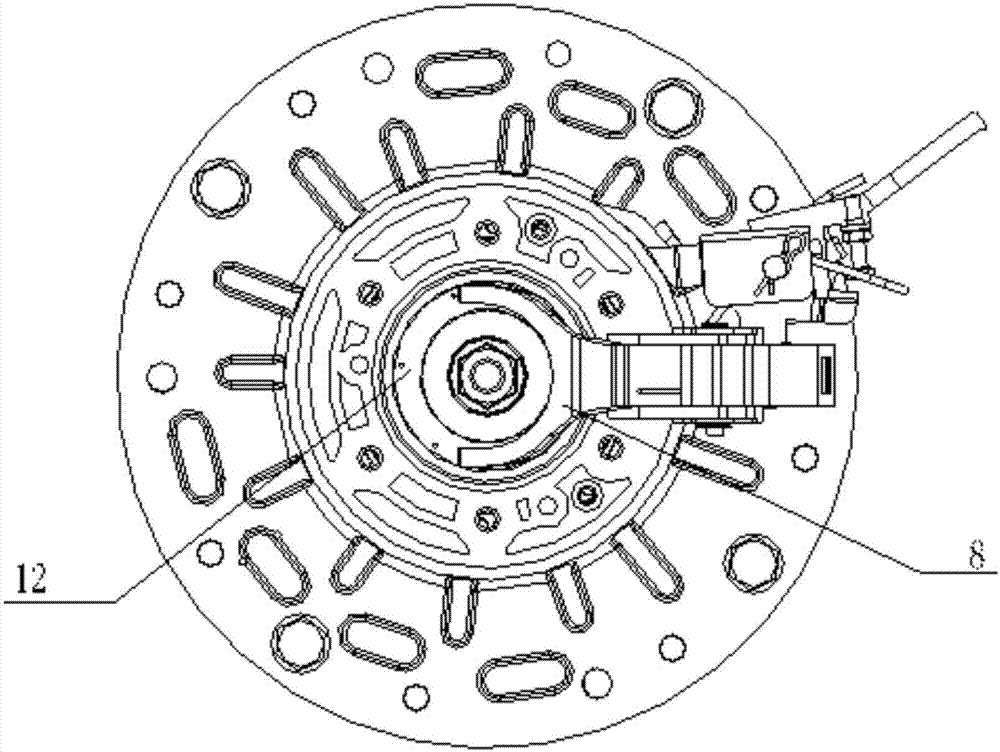

[0055] Such as Figure 1-21 As shown, in this embodiment, the oil inlet end of the oil leakage hole 26 is set outside the oil storage tank 25 and is set close to the outside of the positioning protrusion 27 .

[0056] The above arrangement prevents the lubricating grease in the oil storage tank 25 from being thrown out of the oil storage tank 25 when the clutch sleeve 12 rotates.

[0057] The specification of the oil leakage hole 26 is smaller than that of the oil storage tank 25 , so that the lubricating grease slowly flows to the contact surface between the positioning protrusion 27 and the shift fork 8 .

[0058] A plurality of oil storage grooves 25 are evenly distributed on the positioning protrusion 27 .

[0059] The oil leakage hole 26 is a through hole with a circular cross section.

[0060] A second sealing gasket 29 is provided above the positioning protrusion 27, and a positioning column 30 extending downward and corresponding to the oil storage tank 25 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com