Drying air duct, washing and drying all-in-one machine and control method of drying air duct

An air duct and tuyere technology, applied in the field of washing machines, can solve the problems of low rotation speed of the inner drum, low drying efficiency, and clothes accumulation at the bottom of the drum, etc., so as to reduce the rotation time, improve the drying efficiency, and reduce the generation of clothes dander. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

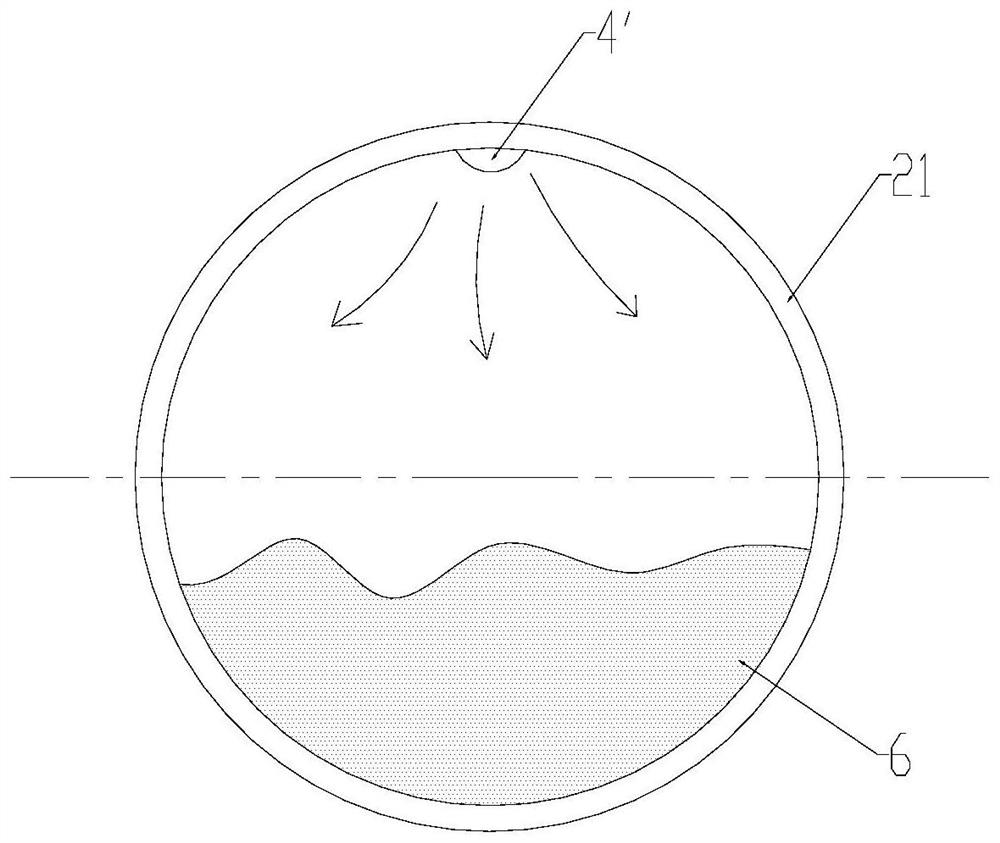

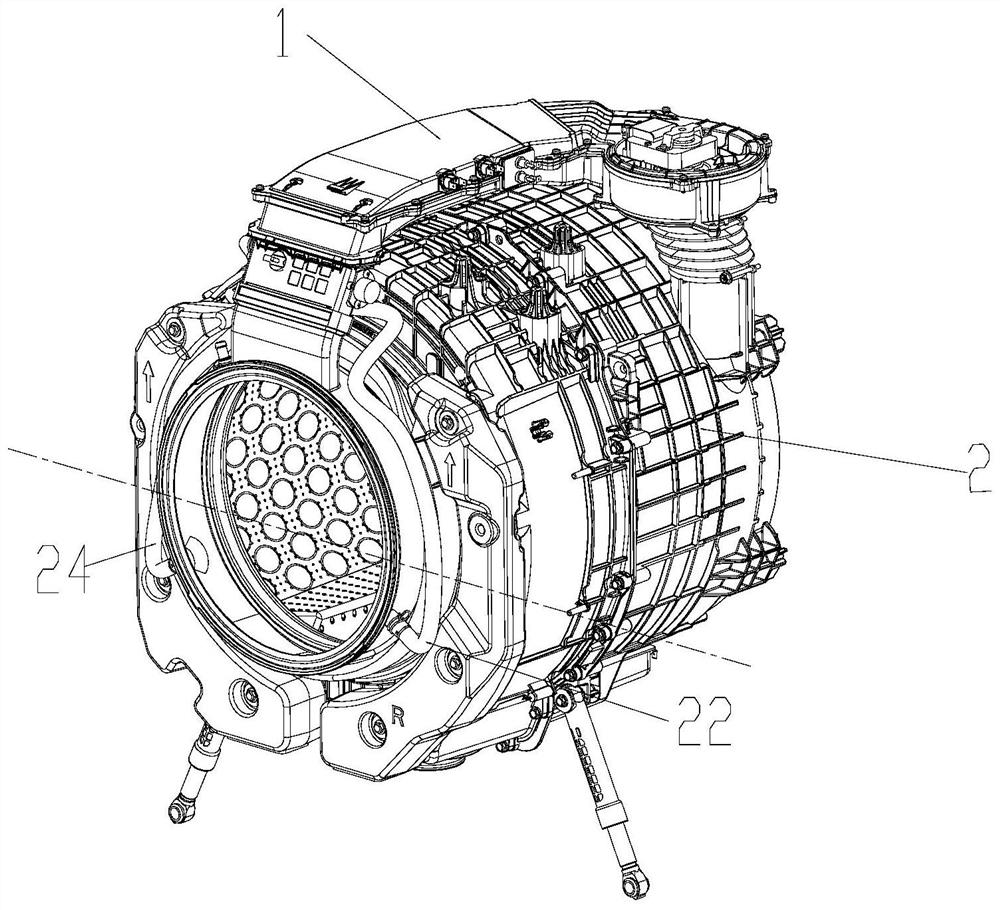

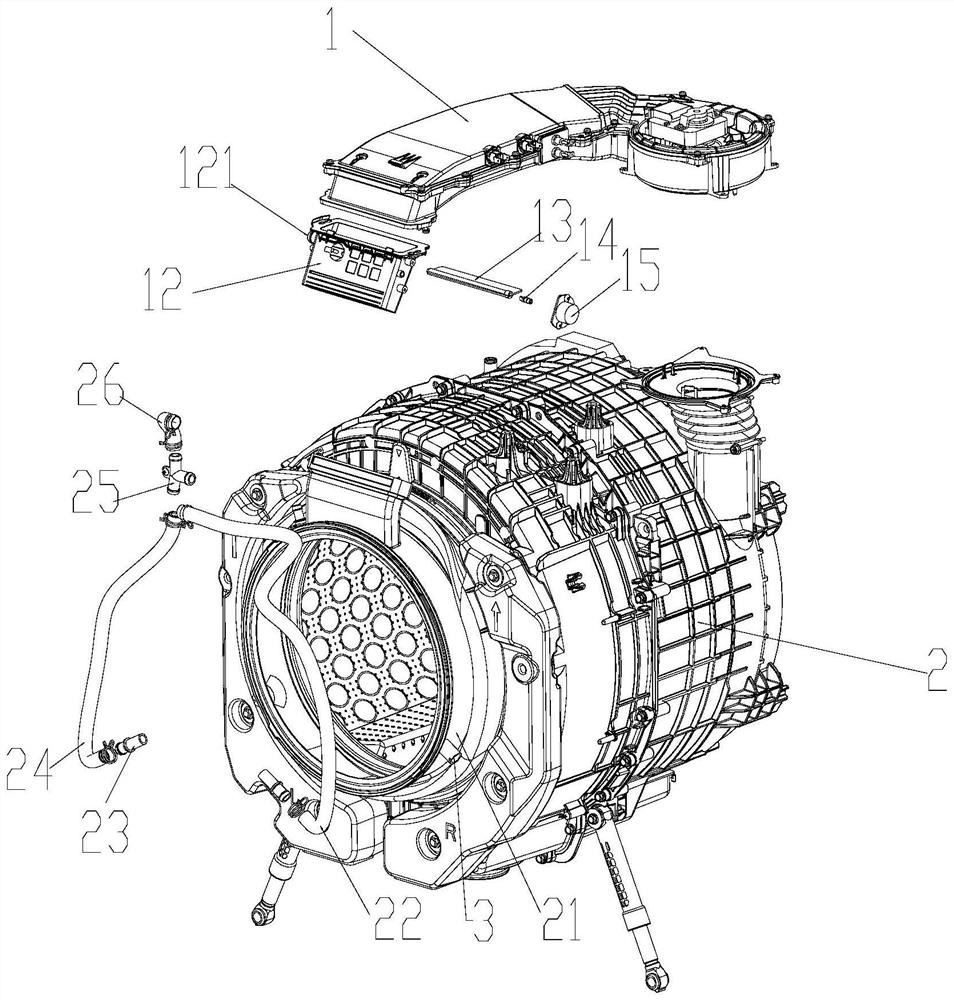

[0042] Such as Figure 2-Figure 9 As shown, this embodiment provides a drying air duct for use in a washing and drying machine, which includes an air duct 1, and a main air inlet 4 and a split air inlet both arranged on the outer door seal assembly 21 3. Among them: the main air inlet 4 and the split air inlet 3 are all connected to the air duct 1, the main air inlet 4 is located above the middle of the door seal assembly 21, and can make the wind blow into the cylinder, and all the split air inlets The air outlets 3 are all located below the middle of the door seal assembly 21, and can make the wind blow into the cylinder.

[0043] Wherein, the above-mentioned tube 2 refers to an inner tube that can rotate and accommodate clothes. In order not to affect the rotation of the drum 2 for washing, the inner wall of the drum 2 cannot be provided with the main air inlet and the split air inlet 3. The main air inlet 4 and the split air inlet 3 are located on the door seal assembly 2...

Embodiment 2

[0060] The door seal assembly 21 is located outside the cylinder 2. Since the washing and drying machine needs to wash clothes, the main air outlet and the split air outlet cannot be located on the side wall of the cylinder. In order to make the air flowing out of the split air inlet 3 blow into the cylinder as much as possible, refer to Figure 6 and Figure 7 As shown, the door seal assembly 21 of this embodiment is also provided with an air guide structure, which is located on the side of the split air inlet 3 away from the cylinder, and can reflect part of the airflow blown out by the corresponding split air inlet 3 to Inside barrel 2. Preferably, the above-mentioned air guiding structure is provided on a side of each split air inlet 3 facing away from the cylinder.

[0061] see Figure 6-Figure 8 As shown, when the wind is blown out from the split air inlet 3, part of it can be reflected into the tube by the air guide structure and blow to the clothes in the tube, and ...

Embodiment 3

[0069] This embodiment provides an integrated washing and drying machine, which includes a drum 2, a door seal assembly 21 arranged outside the drum 2, and the above-mentioned drying air duct.

[0070]The all-in-one washing and drying machine of this embodiment has the above-mentioned drying air duct, which can send air into the cylinder in multiple directions to improve the drying efficiency. The clothes are accumulated at the bottom of the tube, and the wind is blown into the tube from the split air inlet 3; part of the hot air sent by the split air inlet 3 can be blown to the clothes on the upper part of the split air inlet 3, and part of the hot air can be blown to the split air inlet. The clothes in the lower part of the tuyere 3 enable the clothes at the bottom of the drum to exchange heat with the hot air, which improves the drying efficiency, reduces the rotation time required for drying the clothes in the drum, and reduces the generation of clothes dander.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com