Multifunctional straw harvester

A multi-functional, harvester technology, which is applied in the direction of harvesters, agricultural machinery and implements, cutting equipment, etc., can solve the problems of non-adjustable direction of the feeding port of the conveying arm, incomplete adsorption effect of the fan, and failure to achieve the harvesting effect, etc. It achieves the effect of simple and novel structural design, shortened turning time, and avoids stepping on the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

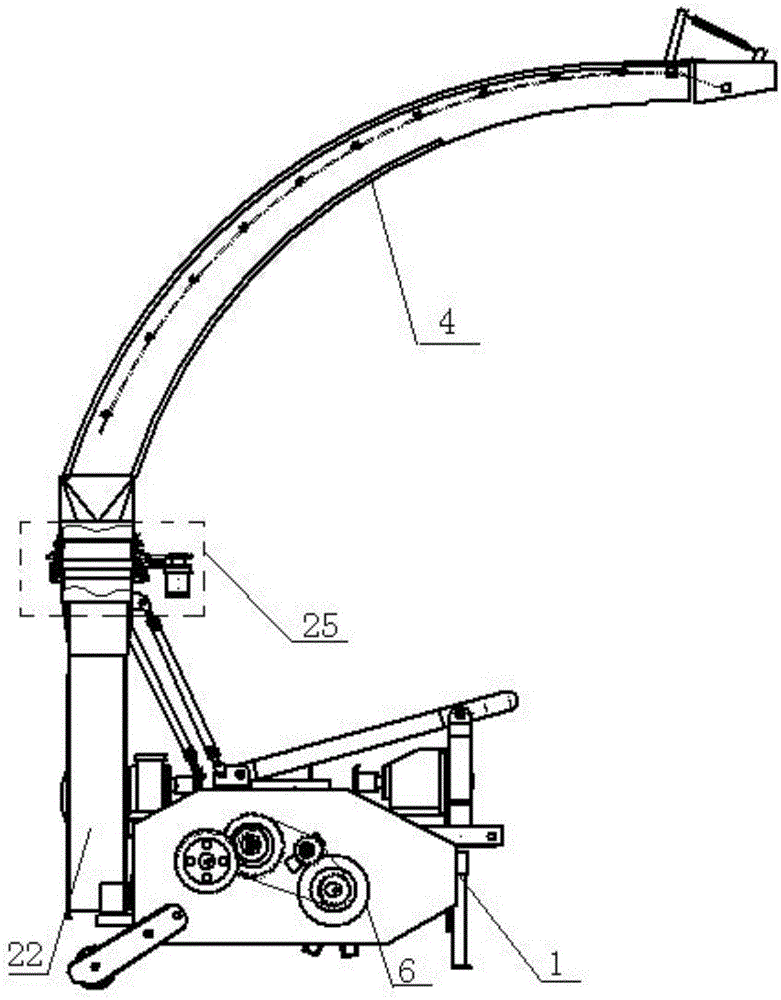

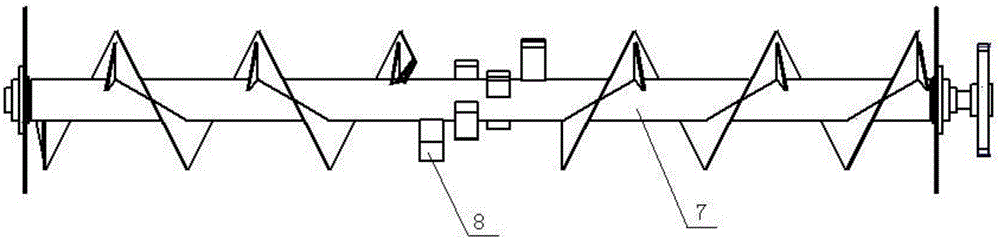

[0027] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Describe this embodiment, this embodiment comprises main engine shell 1, picking up and crushing rotary knife 2, pick-up roller 3, blower fan 22, conveying auger 7 and a plurality of feeding blades 8, and the front end processing of described main engine shell 1 is provided with obliquely The feeding port 1-1, the rear end of the main machine shell 1 is processed with a feeding port 1-2, the feeding port 1-2 is connected with the fan 22, the picking and crushing rotary knife 2, the picking roller 3 and the The conveying auger 7 is located in the shell of the main engine 1, and the conveying auger 7 is arranged near the feeding port 1-2. The material blade 8, the pick-up roller 3 is arranged close to the material inlet 1-1, and the pick-up and crushing rotary knife 2 is arranged on the pick-up roller 3, and it is characterized in ...

specific Embodiment approach 2

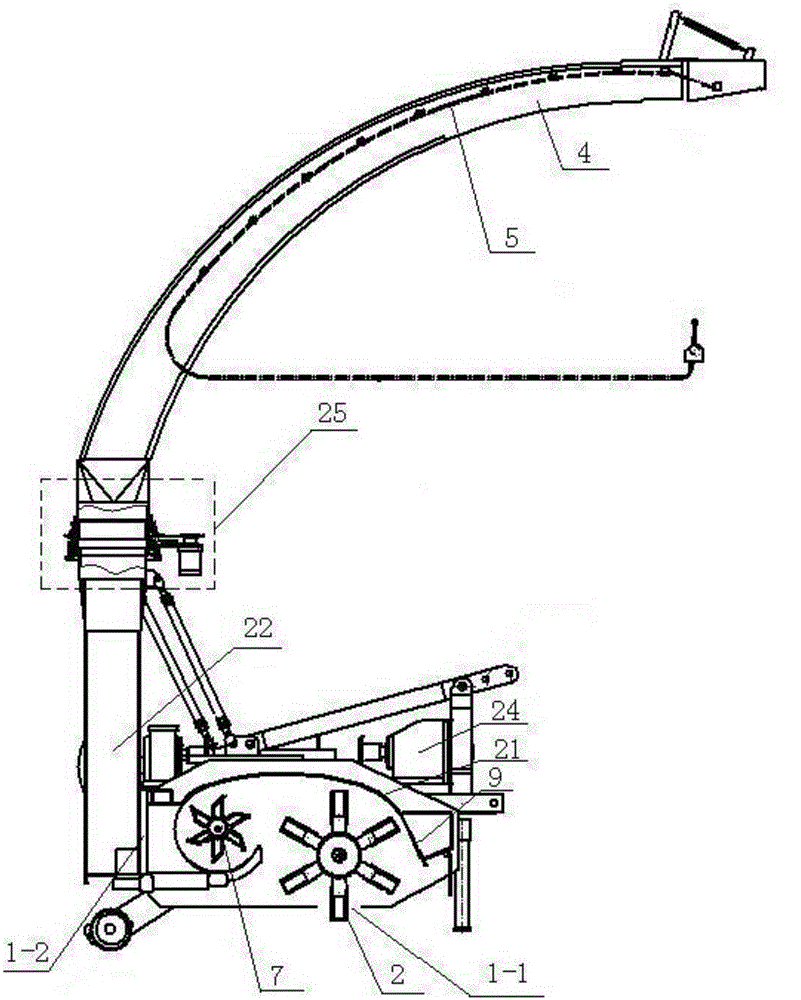

[0030] Specific implementation mode two: combination figure 1 , figure 2 and Figure 6 Describe this embodiment mode, the top end of described feeding arm 4 in this embodiment mode is a material injection port, and described manual adjustment device 5 is arranged at the material injection port place, and described manual adjustment device 5 comprises block 5-1, extension spring Bracket 5-2, extension spring 5-3, tension bar 5-4 and manual control valve 5-5, described stopper 5-1 is facing the material injection opening, and the upper end face of stopper 5-1 is connected with the feeding arm 4 The tube wall of the tube is hinged, the extension spring bracket 5-2 is fixedly connected between the feeding arm 4 and the stopper 5-1, the extension spring 5-3 is arranged on the extension spring bracket 5-2, and the tension bar 5-4 Arranged along the length direction of the feeding arm 4, one end of the tie bar 5-4 is detachably connected to the block 5-1, and the other end of the ...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 and Figure 7 Describe this embodiment, the automatic rotating device 25 of conveying arm described in this embodiment includes hydraulic motor 11, driving sprocket 12, driven sprocket 13, chain 14, swivel joint, outer support sleeve 17, inner support sleeve 18 , the bearing 19 and the connecting frame 20, the outer support sleeve 17 and the inner support sleeve 18 are coaxially arranged, the bottom end of the inner support ring 18 is sleeved in the outer support ring 17, the inner support ring 18 and the outer support ring 17 Bearings 19 are arranged between them, the top end of the inner support sleeve 18 is fixedly connected with a rotary joint, the outer support ring 17 is detachably connected with the hydraulic motor 11 through the connecting frame 20, and the output shaft of the hydraulic motor 11 is set with a driving chain Wheel 12, the driven sprocket 13 is set on the inner support sleeve 18 and is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com