Pulverized coal burner for efficient ignition and combustion of asphalt mixing plants

A technology of asphalt mixing plant and pulverized coal burner, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, which can solve the problem of low pulverized coal combustion efficiency, burning out of carbon deposits on ignition guns, and short service life. problem, to achieve stable and sufficient combustion, prevent flame spread, and improve the effect of combustion utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

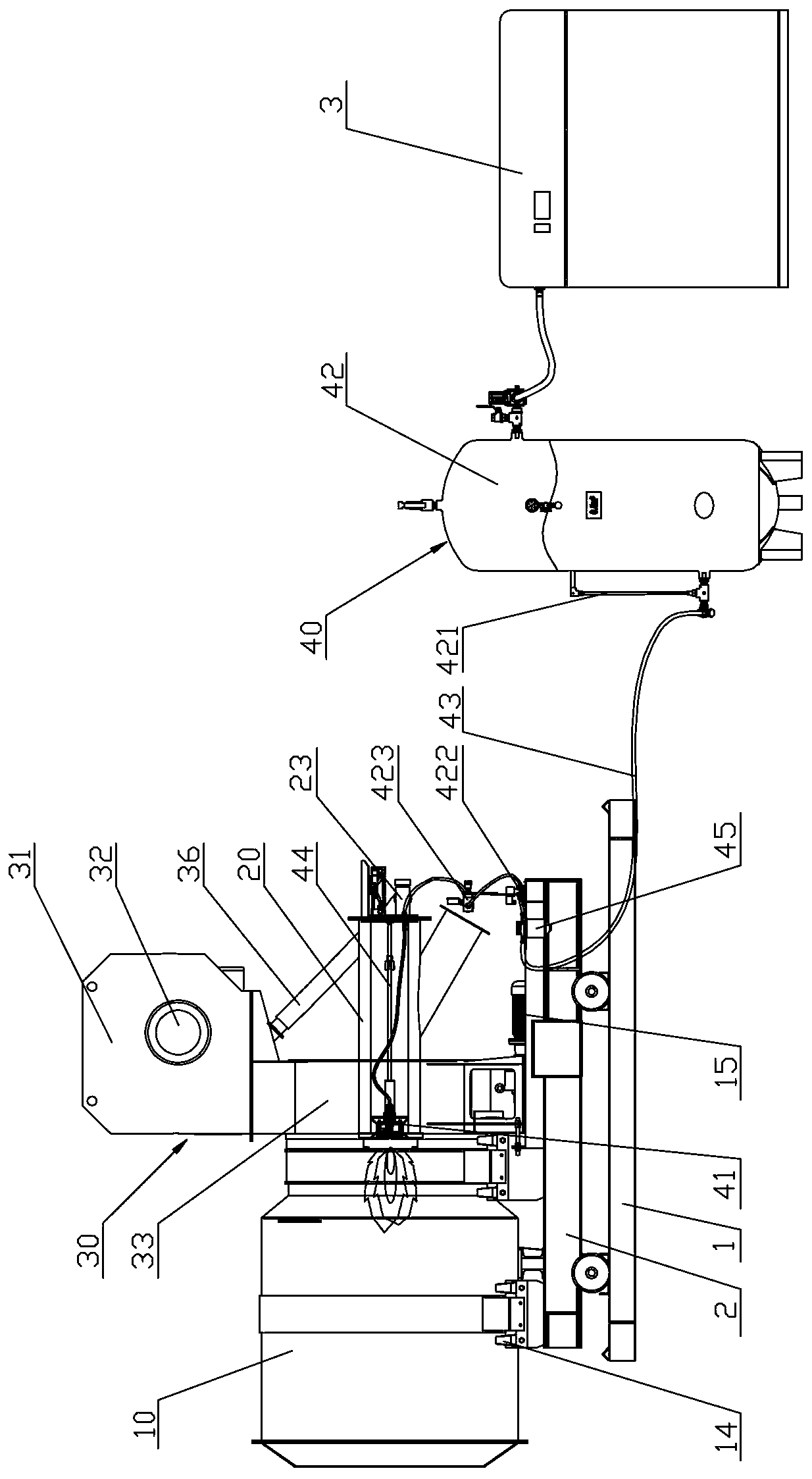

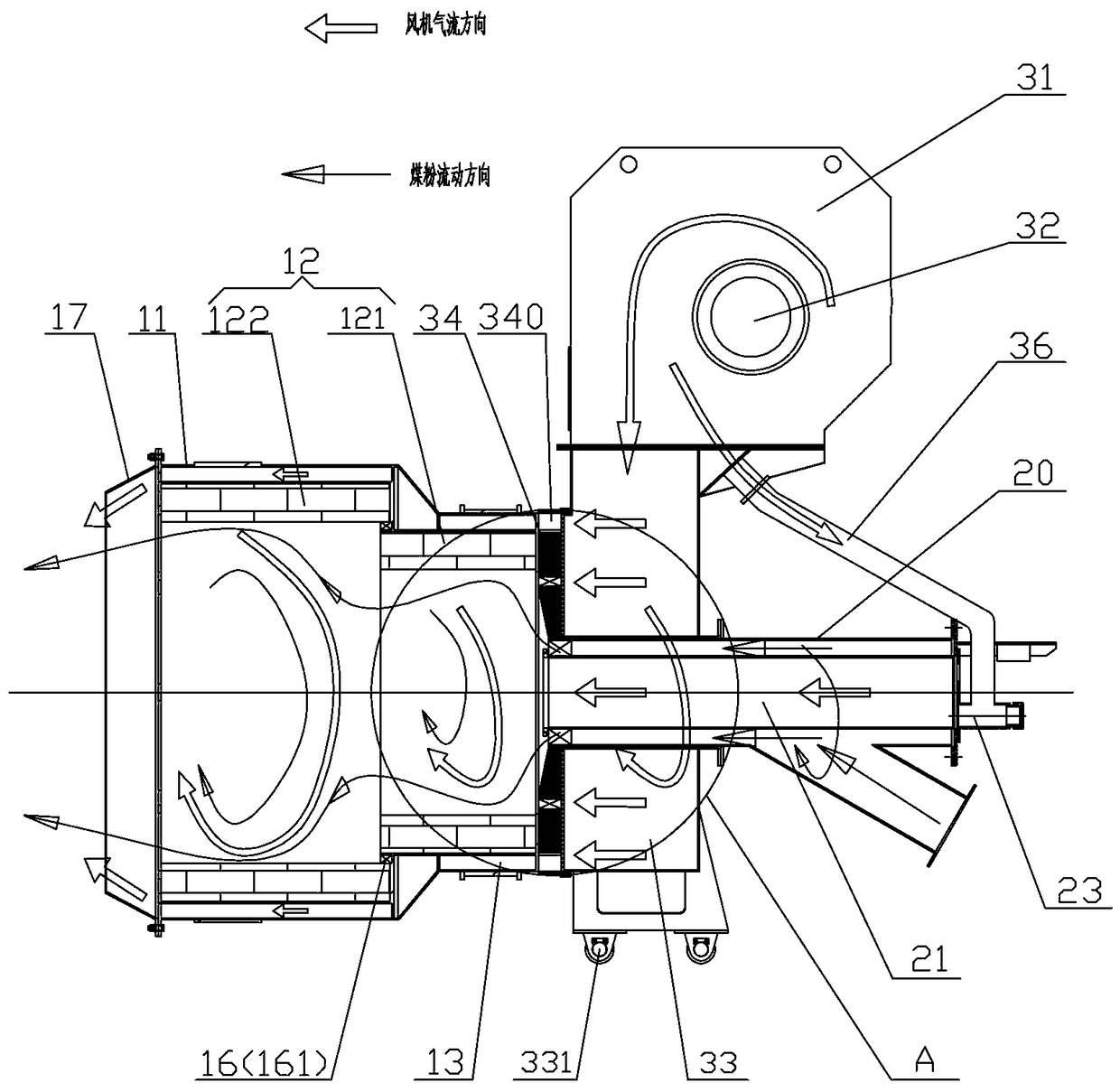

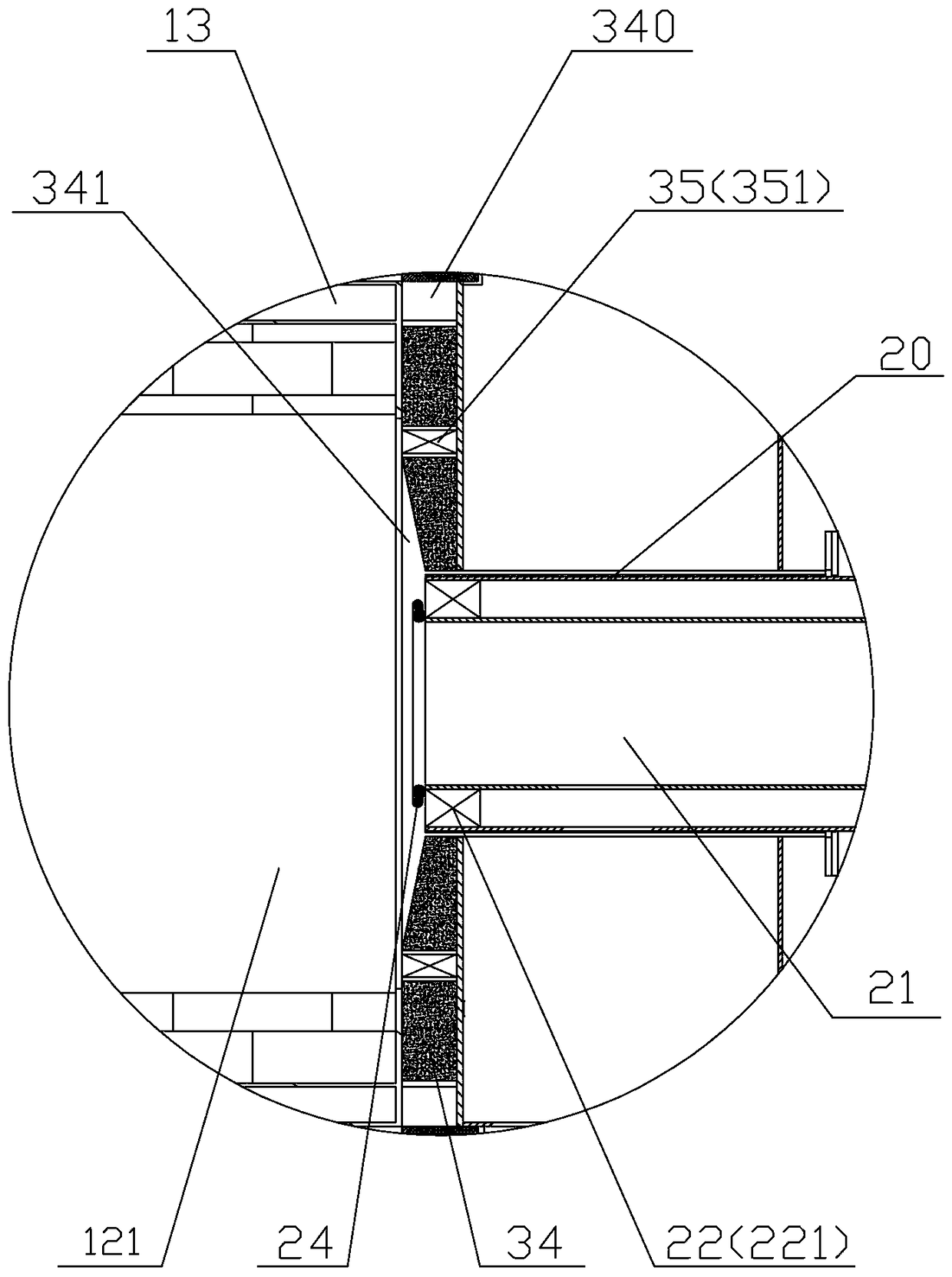

[0029] Pulverized coal burners for high-efficiency ignition and combustion of asphalt mixing plants, see figure 1 and figure 2 , including a bracket 1, a furnace body 10, a coal delivery pipe 20, an air induction device 30 and an ignition system 40, the furnace body includes a casing 11 and a furnace 12, an air inlet cavity 13 is formed between the casing 11 and the furnace 12, and the casing passes through a plurality of Two rollers 14 are supported on a support base 2, and the support base 2 is located on the support 1, and the support base 2 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com