Super-multielement high-entropy ceramic as well as preparation method and application thereof

A multi-element high-entropy, ceramic technology, applied in the field of ceramic materials, can solve the problems of unreported preparation and research of high-entropy ceramics, and achieve the effects of improving the driving force of sintering, the method is simple, and the cooling speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

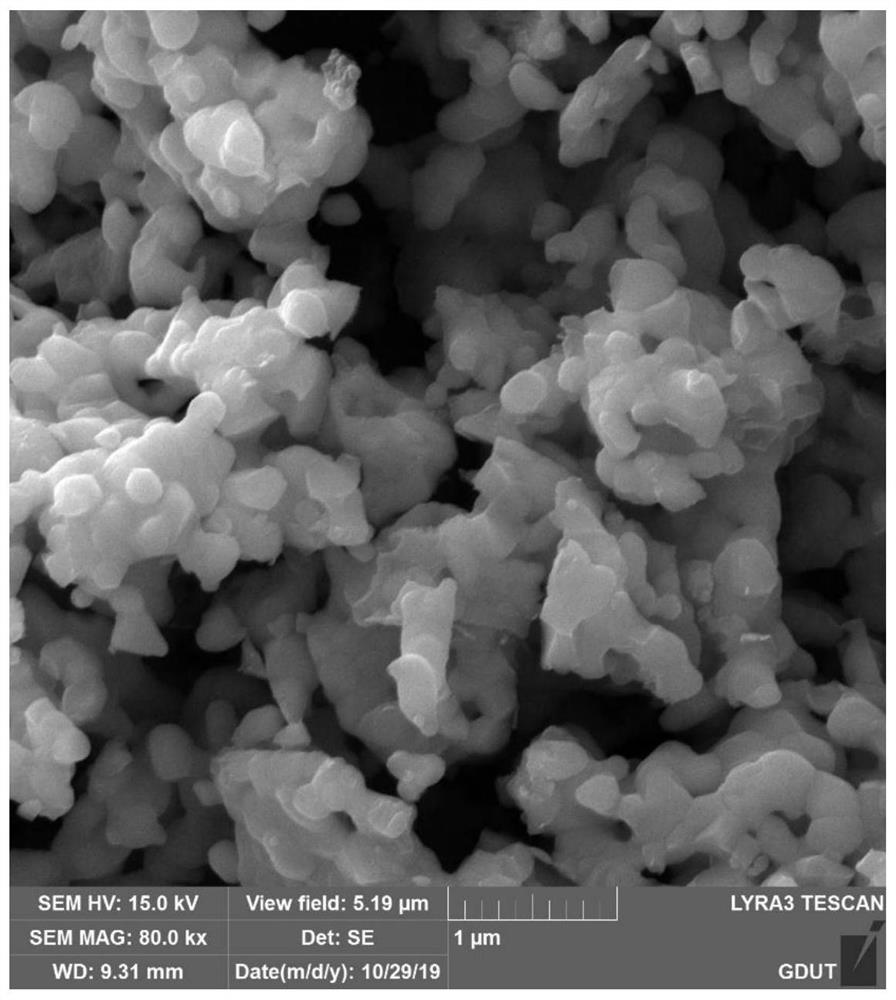

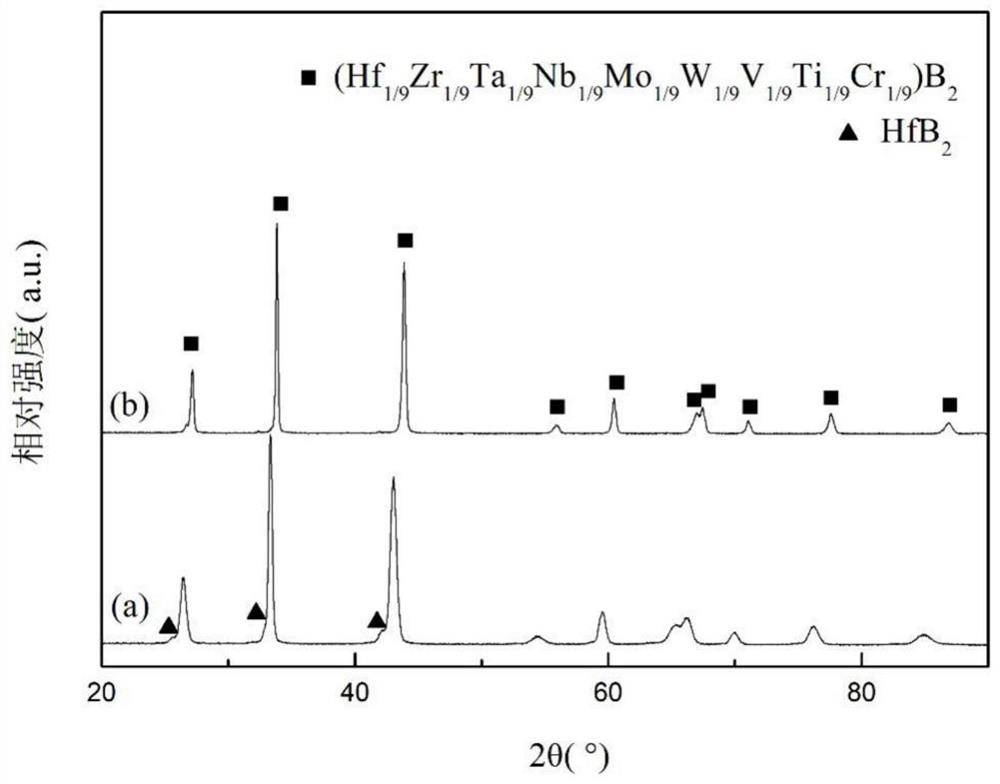

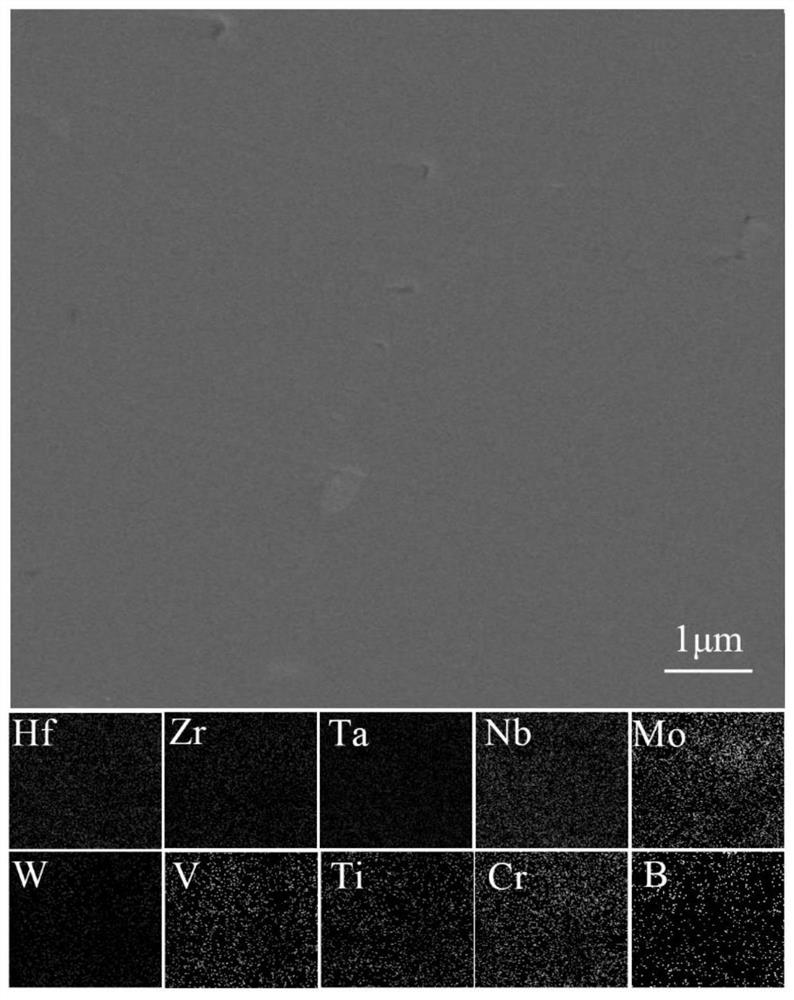

Embodiment 1

[0033] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 10μm), Nb 2 o 5 (powder purity 99.9%, particle size 1μm) powder, V 2 o 5 (powder purity 99.9%, particle size 1μm) powder, WO 3 (Powder purity 99.9%, particle size 1μm) powder, MoO 3 (Powder purity 99.9%, particle size 1μm) powder, TiO 2 (Powder purity 99.9%, particle size 4μm) and Ta 2 o 5 (Powder purity 99.9%, particle size 1 μm) powder and B (powder purity 99.9%, particle size 2 μm) were mixed with ethanol, and Si 3 N 4 The ball is the ball milling medium, and the ball-to-material ratio is 2:1 and mixed for 24 hours.

[0034] 2. Boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratio of boron powder and Nb is 3.67:1. 2 o 5 , V 2 o 5 and Ta 2 o 5 The molar ratio of boron powder and Cr is 8.07:1. 2 o 3 The molar ratio of boron powder to MoO is 8.8:1 3 and WO 3 The molar ratio is 4.4:1.

[0035] 3....

Embodiment 2

[0040] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 1μm), Nb 2 o 5 (powder purity 99.9%, particle size 1μm) powder, V 2 o 5 (powder purity 99.9%, particle size 1μm) powder, WO 3 (Powder purity 99.9%, particle size 1μm) powder, MoO 3 (powder purity 99.9%, particle size 2μm) powder, TiO 2 (Powder purity 99.9%, particle size 4μm) and Ta 2 o 5 (Powder purity 99.9%, particle size 1 μm) powder and B (powder purity 96.9%, particle size 10 μm) were mixed with ethanol, and Si 3 N 4 The ball is the ball milling medium, and the ball-to-material ratio is 3:1 and mixed for 24 hours.

[0041] 2. Boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratio of boron powder and Nb is 3.78:1. 2 o 5 , V 2 o 5 and Ta 2 o 5 The molar ratio of boron powder and Cr is 8.34:1. 2 o 3 The molar ratio of boron powder to MoO is 8.9:1 3 and WO 3 The molar ratio is 4.2:1.

[0042] 3....

Embodiment 3

[0046] 1. With HfO 2 (powder purity 99.9%, particle size 1μm), ZrO 2 (powder purity 99.9%, particle size 1μm), Cr 2 o 3 (powder purity 99.9%, particle size 10μm), Nb 2 o 5 (powder purity 99.9%, particle size 1μm) powder, V 2 o 5 (powder purity 99.9%, particle size 1μm) powder, WO 3 (Powder purity 99.9%, particle size 3μm) powder, MoO 3 (powder purity 99.9%, particle size 2μm) powder, TiO 2 (Powder purity 99.9%, particle size 4μm) and Ta 2 o 5 (Powder purity 99.9%, particle size 1 μm) powder and B (powder purity 99.9%, particle size 2 μm) were mixed with ethanol, and Si 3 N 4 The ball is a ball milling medium, the ratio of ball to material is 4:1, and the mixture is mixed for 28 hours.

[0047] 2. Boron powder and HfO 2 , ZrO 2 and TiO 2 The molar ratio of boron powder and Nb is 3.9:1. 2 o 5 , V 2 o 5 and Ta 2 o 5 The molar ratio of boron powder and Cr is 9:1. 2 o 3 The molar ratio of boron powder to MoO is 8.5:1 3 and WO 3 The molar ratio is 4.4:1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com