Preparation process of high-performance piezoelectric ceramic

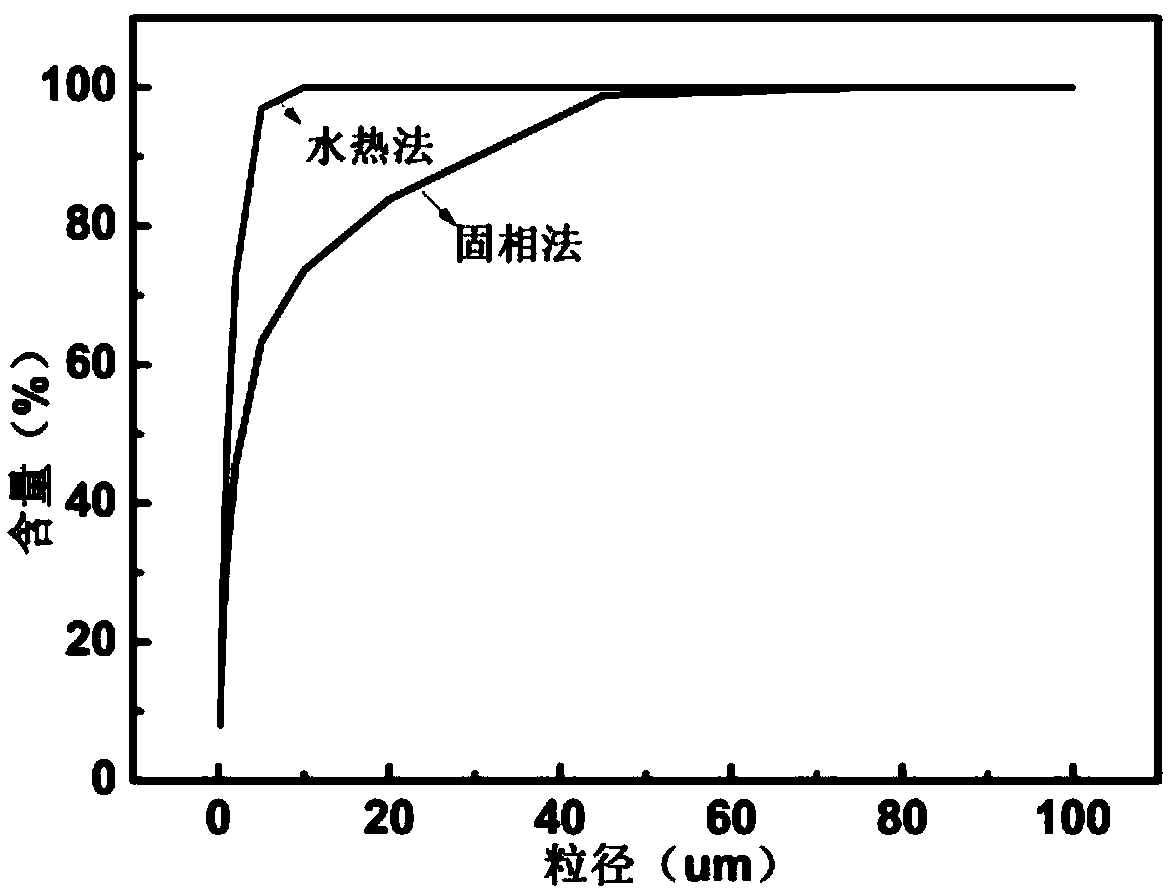

A technology for piezoelectric ceramics and preparation process, which is applied in the field of preparation technology of high-performance piezoelectric ceramics, can solve the problems of difficult process stability, increase the cost of ceramic raw materials, complex reaction system, etc., and achieves narrow particle size distribution range and raw material cost. Reduced, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0034] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0035] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 70°C to dry to obtain a powder;

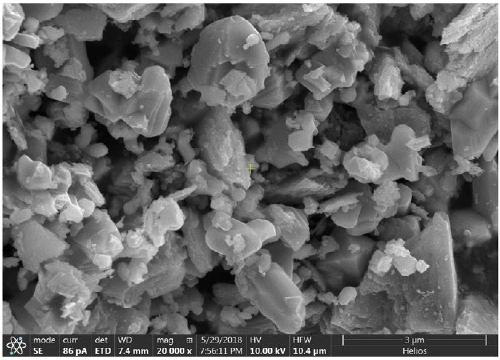

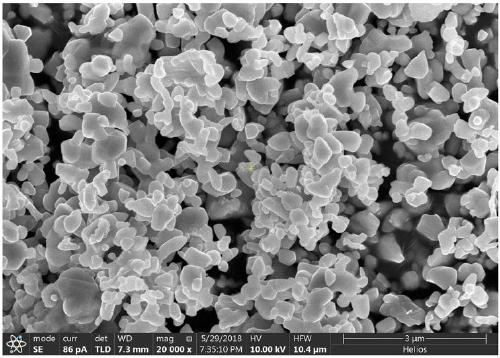

[0036] 3) Add water to the powder, then add ammonia water, and then heat for hydrothermal treatment. In the reaction system of hydrothermal treatment, the concentration of ammonia water is 1mol / L, the treatment temperature of hydrothermal treatment is 300°C, and the treatment time of hydrothermal treatment is 15h. The powder after hydrothermal treatment is dried in a drying oven at 70°C to obtain piezoelectric ceramic raw material powder;

[0037] 4) Add 300 g of deionized...

Embodiment 2

[0038] Embodiment 2: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0039] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0040] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 60° C. to dry to obtain a powder;

[0041] 3) Add water to the powder, then add citric acid, then heat for hydrothermal treatment, the concentration of citric acid in the reaction system of hydrothermal treatment is 0.5mol / L, the treatment temperature of hydrothermal treatment is 200°C, and the treatment time of hydrothermal treatment is After 25 hours, the hydrothermally treated powder was dried in a drying oven at 60°C to obtain piezoelectric ceramic raw material powder;

[0042] 4) Add 250 g of deionize...

Embodiment 3

[0043]Embodiment 3: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0044] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0045] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 120° C. to dry to obtain a powder;

[0046] 3) Add water to the powder, then add oxalic acid, and then heat for hydrothermal treatment. In the reaction system of hydrothermal treatment, the concentration of oxalic acid is 2mol / L, the treatment temperature of hydrothermal treatment is 400°C, and the treatment time of hydrothermal treatment is 5h. The powder after hydrothermal treatment is dried in a drying oven at 80°C to obtain piezoelectric ceramic raw material powder;

[0047] 4) Add 350 g of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com