3D printing composite material with SEBS wrapping metal tungsten and preparation method thereof

A composite material, 3D printing technology, applied in metal processing equipment, nanotechnology for materials and surface science, additive processing, etc., can solve the problems of good radiation absorption characteristics of lead, toxicity offset, product weight, etc. The effect of good effect, good ball shape, excellent mechanical strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments.

[0027] The SEBS-coated tungsten 3D printing composite material of the present invention is a spherical or near-spherical composite powder material with radiation protection functional powder coated with metal tungsten by SEBS; the SEBS raw material is selected as a high-molecular-weight star-shaped structure.

[0028] The composite material is prepared from the following raw materials: 30 parts of thermoplastic elastomer SEBS, 70 parts of nano-tungsten powder, and solvent acetone. The total weight component of SEBS and tungsten powder fusion coating is 100.

[0029] The thermoplastic elastomer SEBS is selected as Baling Petrochemical SEBS model YH-602T.

[0030] Nano-tungsten powder is nano-sized tungsten powder with good sphericity produced by plasma vapor phase evaporation method, with an average particle size of 0.2 μm.

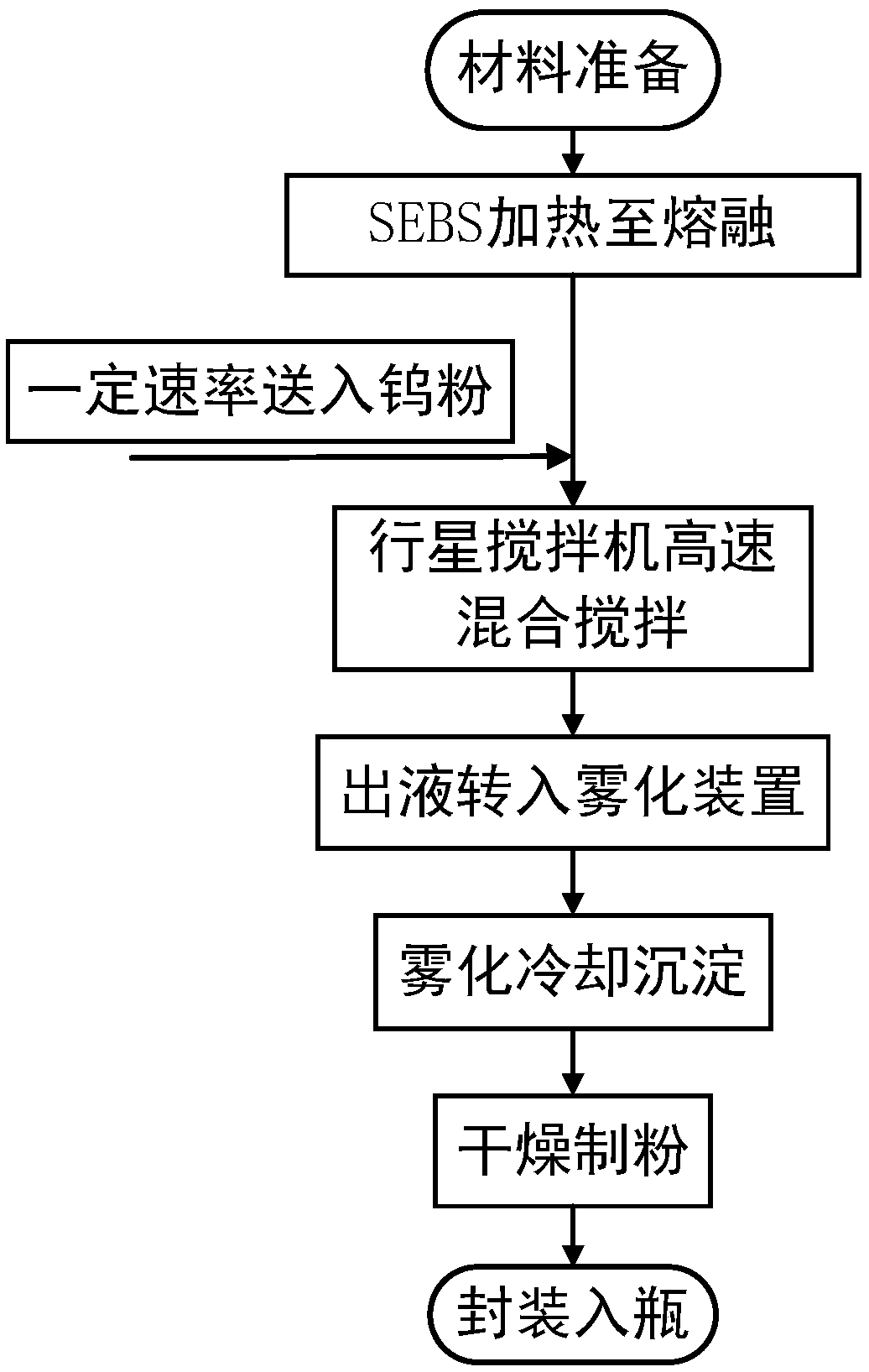

[0031] The preparation process is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com