A kind of method that utilizes waste EVA-based material to prepare composite regenerated foam material

A technology of composite regeneration and foam materials, applied in recycling technology, plastic recycling, etc., can solve problems such as economic impact, achieve easy operation, realize high-value recycling, and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

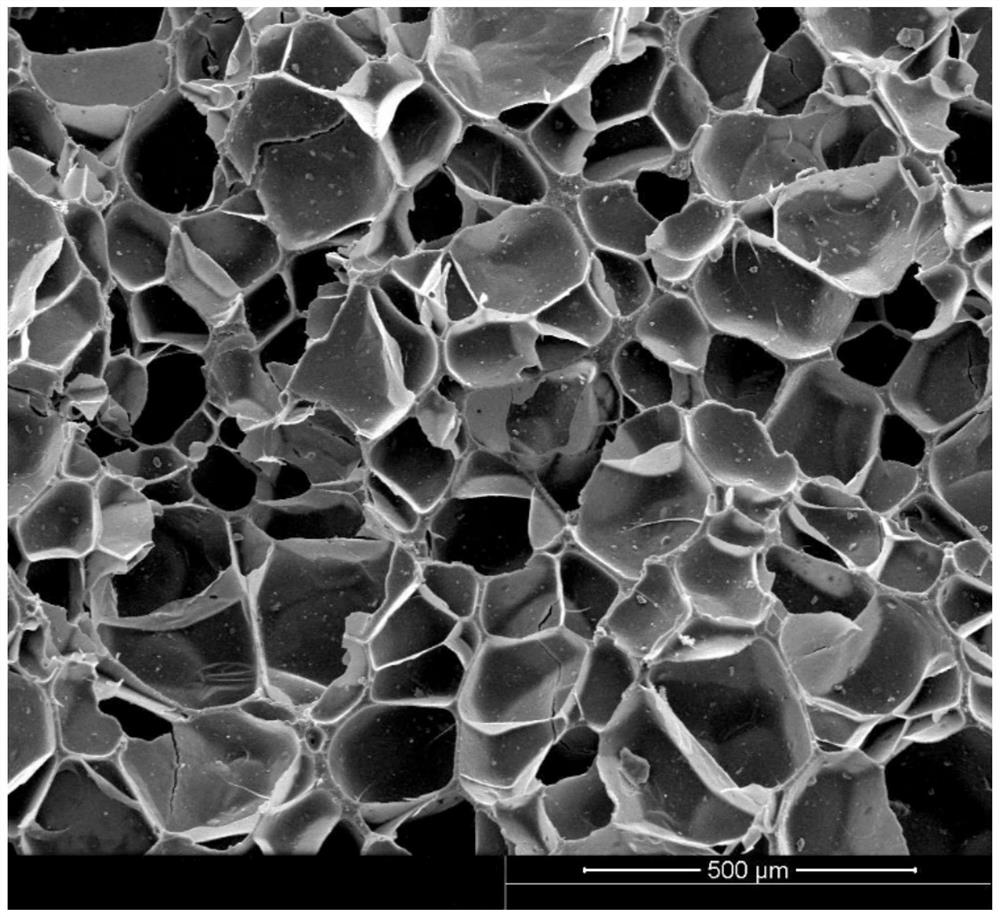

[0067] The present embodiment a kind of method that utilizes waste EVA base material to prepare composite regenerated foam material, mainly comprises the following steps in parts by weight:

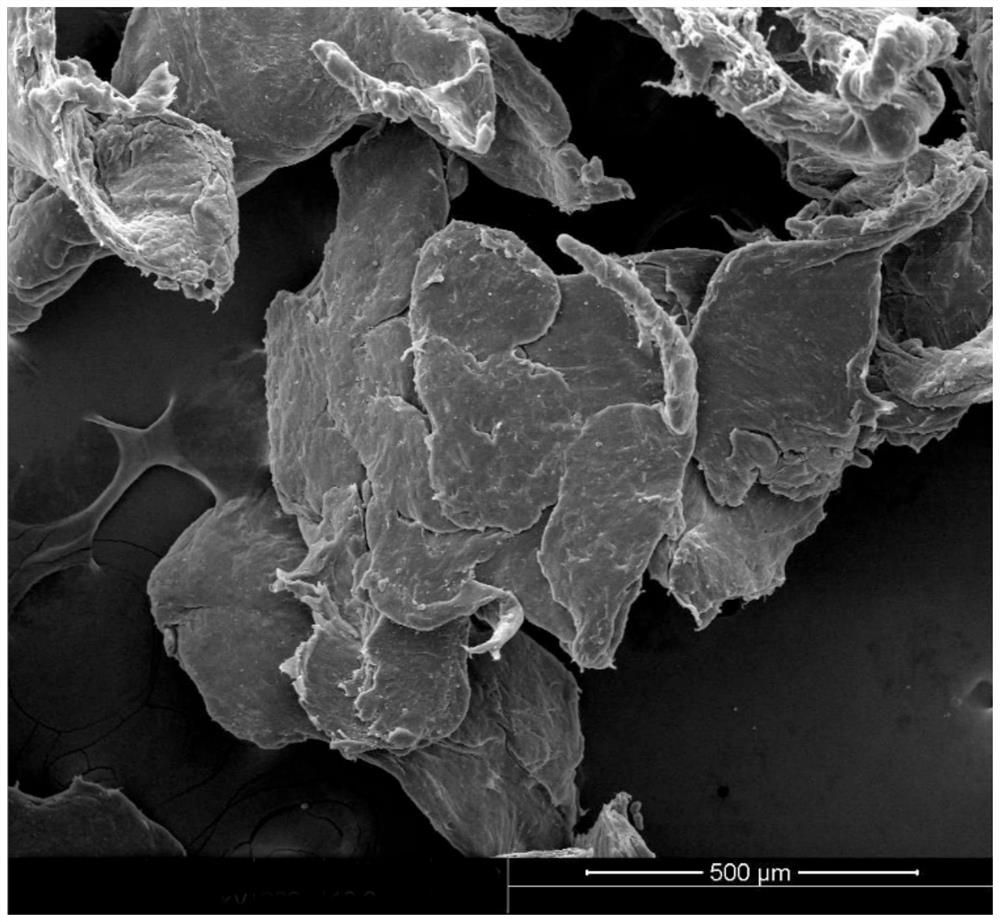

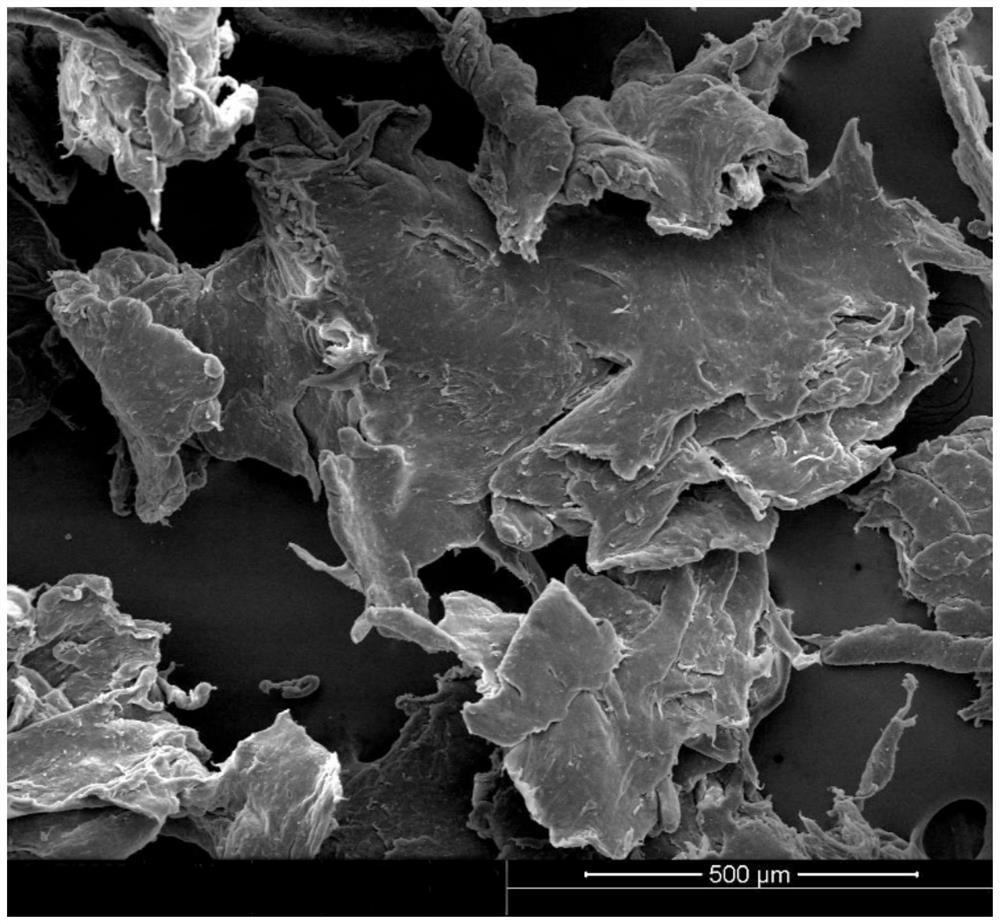

[0068] (1) the waste EVA-based sole foam product, after pretreatment such as cleaning, is processed and roughly pulverized to the waste EVA-based material with a particle size of 10 to 20 mm;

[0069] (2) adding the waste EVA base material into the grinding disc-shaped solid-phase mechanochemical reactor for grinding and pulverizing, and after the grinding is completed, collect the waste EVA base ultrafine flake powder; wherein, the grinding-disc-shaped solid-phase mechanochemical reactor The process parameters are: the grinding pressure is 0.5MPa, the grinding surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -16 °C, the circular grinding is performed 12 times, and the grinding disc speed is 45 rpm;

...

Embodiment 2

[0074] The present embodiment a kind of method that utilizes waste EVA base material to prepare composite regenerated foam material, mainly comprises the following steps in parts by weight:

[0075] (1) the waste EVA-based sole foam product, after pretreatment such as cleaning, is processed and roughly pulverized to the waste EVA-based material with a particle size of 10 to 20 mm;

[0076] (2) adding the waste EVA base material into the grinding disc-shaped solid-phase mechanochemical reactor for grinding and pulverizing, and after the grinding is completed, collect the waste EVA base ultrafine flake powder; wherein, the grinding-disc-shaped solid-phase mechanochemical reactor The process parameters are: the grinding pressure is 0.4 MPa, the grinding surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -14 °C, and the circular grinding is performed 10 times, and the grinding disc rotating speed ...

Embodiment 3

[0116] The present embodiment a kind of method that utilizes waste EVA base material to prepare composite regenerated foam material, mainly comprises the following steps in parts by weight:

[0117] (1) the waste EVA-based sole foam product, after pretreatment such as cleaning, is processed and roughly pulverized to the waste EVA-based material with a particle size of 10 to 20 mm;

[0118] (2) adding the waste EVA base material into the grinding disc-shaped solid-phase mechanochemical reactor for grinding and pulverizing, and after the grinding is completed, collect the waste EVA base ultrafine flake powder; wherein, the grinding-disc-shaped solid-phase mechanochemical reactor The process parameters are: the grinding pressure is 0.8MPa, the temperature of the grinding surface of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of -10 °C, the circular grinding is performed 10 times, and the grinding disc speed is 50 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com