A preparation method of inert powder for suppressing starch deflagration

A technology of inerting powder and deflagration, which is applied in the fields of silicon oxide, silicon dioxide, fire rescue, etc. It can solve the problems of low explosion suppression effect, no inorganic silicon powder inerting explosion suppression, and difficulty in uniform mixing of combustible dust, etc. , to achieve the effects of excellent explosion suppression performance, widening resource utilization and high value-added utilization, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example provides a preparation method of an inert powder that suppresses starch deflagration. NaOH is dissolved in quantitative water, and the concentration of NaOH is 8mol*L -1 , and place it in a constant temperature water bath at 60° C. to obtain a chemical modifier solution.

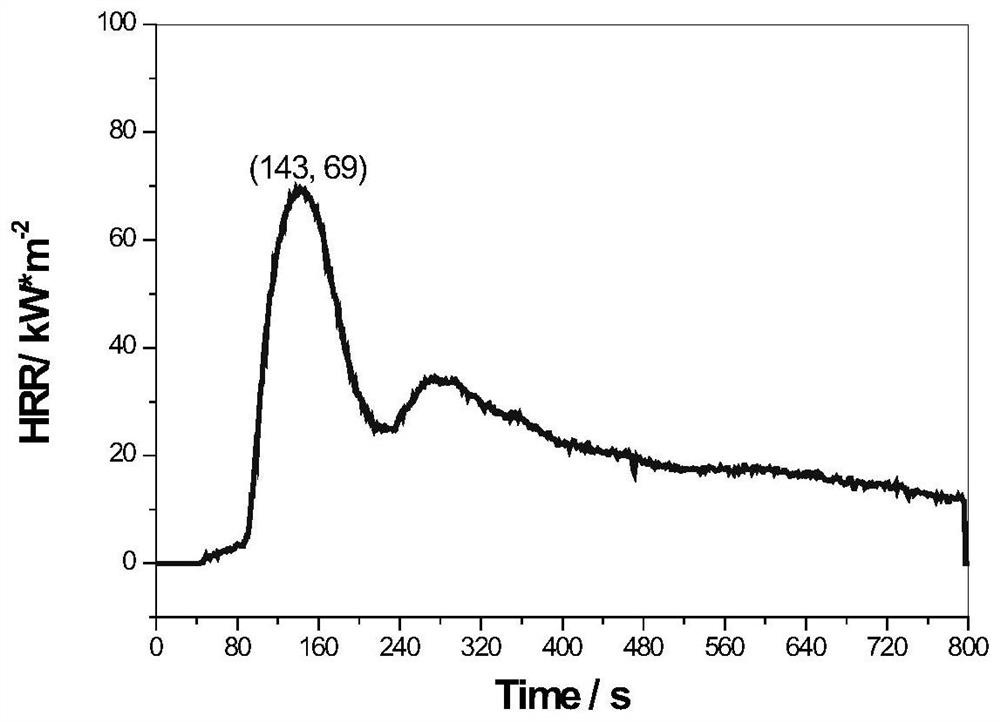

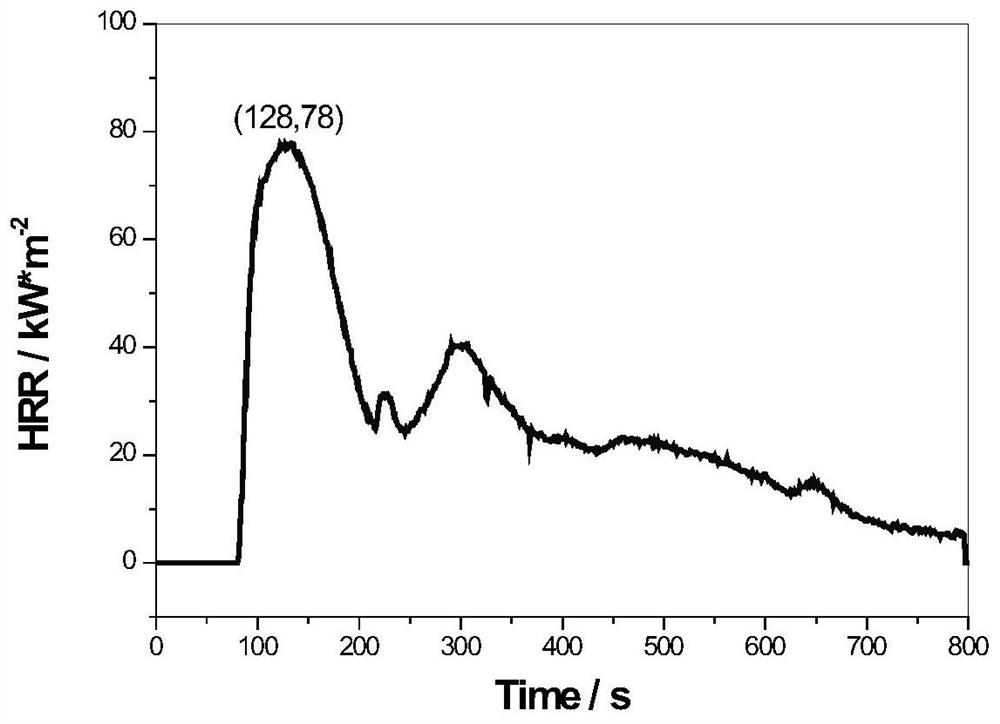

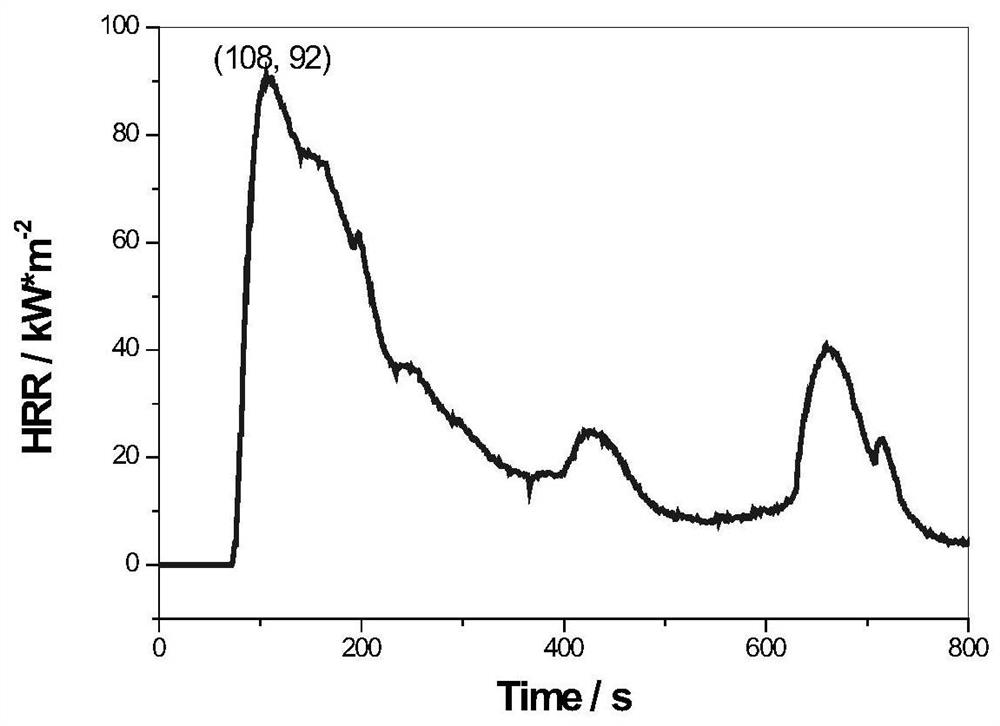

[0025] Then slowly add 100g of diatomaceous earth into 200mL of NaOH solution in a magnetic stirrer, stir for 15min, then ultrasonicate for 5min and impregnate in air isolation, and finally wash with water until pH = 7, filter, dry, and grind to obtain an inert powder , fully mix it with starch in a mortar (inert powder: starch = 1:10, wt%), and use 1.2L Hartmann Tube test its explosion, explosion pressure rise rate, maximum explosion pressure, etc. In order to further confirm its combustion characteristics, its heat release performance was tested with a cone calorimeter (about 550°C) with reference to the GB / T 16172-2007 "Test Method for Heat Release Rate of Building Materials". The res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com