Composite powder explosion suppressant based on modified montmorillonite powder and preparation method of composite powder explosion suppressant

A technology of montmorillonite powder and composite powder, which is applied in the fields of chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of poor explosion suppression effect, and achieve excellent explosion suppression performance, high efficiency, and easy-to-control conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

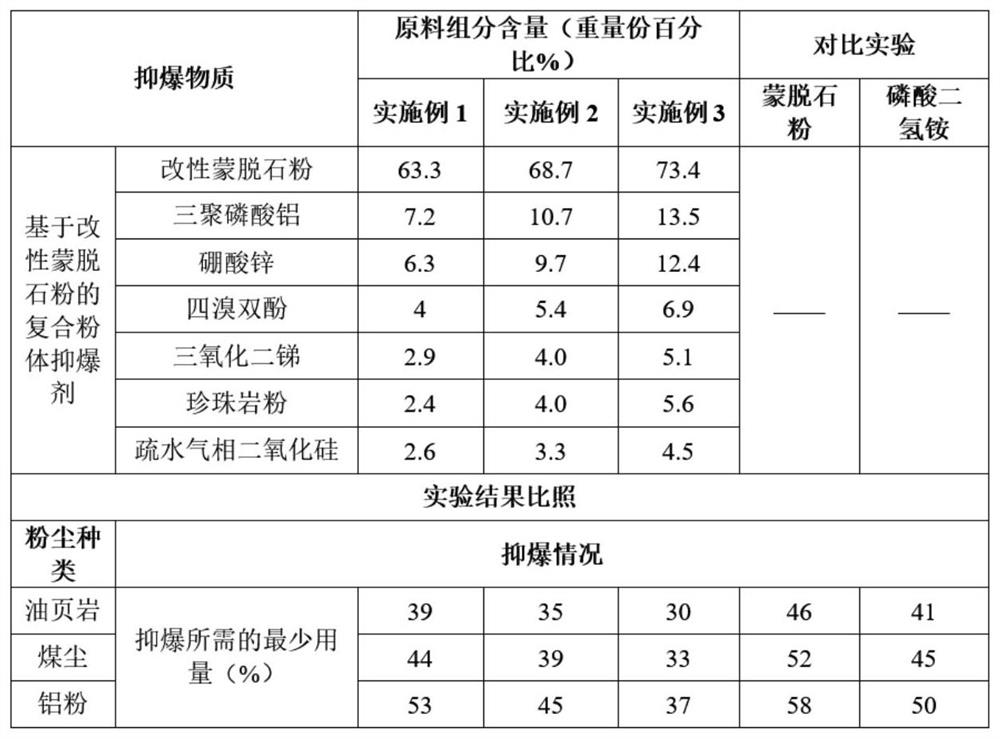

[0028] The composite powder antiknock agent based on modified montmorillonite powder in the present embodiment, its raw material percentage by weight is: modified montmorillonite powder 63.3%, aluminum tripolyphosphate 7.2%, zinc borate 6.3%, tetrabromobis 4.0% phenol, 2.9% antimony trioxide, 2.4% perlite powder, 2.6% hydrophobic fumed silica.

[0029] Wherein, the modified montmorillonite powder is prepared by the following method: Weigh a certain amount of montmorillonite powder, add concentrated sulfuric acid to acidify in a water bath at 70°C, wash with deionized water until neutral, and obtain acidified montmorillonite powder, drying, and then using an aluminate coupling agent (distearoyloxyisopropyl aluminate) to modify the acidified montmorillonite powder to obtain the modified montmorillonite powder.

[0030] The preparation method of the composite powder explosion suppressing agent based on modified montmorillonite powder is as follows:

[0031] Step 1. Put the modif...

Embodiment 2

[0036] The composite powder antiknock agent based on modified montmorillonite powder in the present embodiment, its raw material percentage by weight is: modified montmorillonite powder 68.7%, aluminum tripolyphosphate 10.7%, zinc borate 9.7%, tetrabromobis Phenol 5.4%, antimony trioxide 4.0%, perlite powder 4.0%, hydrophobic fumed silica 3.3%.

[0037] Wherein, the modified montmorillonite powder is prepared by the following method: Weigh a certain amount of montmorillonite powder, add concentrated sulfuric acid to acidify in a water bath at 70°C, wash with deionized water until neutral, and obtain acidified montmorillonite powder, drying, and then using an aluminate coupling agent (distearoyloxyisopropyl aluminate) to modify the acidified montmorillonite powder to obtain the modified montmorillonite powder.

[0038] The preparation method of the composite powder explosion suppressing agent based on modified montmorillonite powder is as follows:

[0039] Step 1. Put the modi...

Embodiment 3

[0044] The composite powder antiknock agent based on modified montmorillonite powder in the present embodiment, its raw material percentage by weight is: modified montmorillonite powder 73.4%, aluminum tripolyphosphate 13.5%, zinc borate 12.4%, tetrabromobis Phenol 6.9%, antimony trioxide 5.1%, perlite powder 5.6%, hydrophobic fumed silica 4.5%.

[0045] Wherein, the modified montmorillonite powder is prepared by the following method: Weigh a certain amount of montmorillonite powder, add concentrated sulfuric acid to acidify in a water bath at 70°C, wash with deionized water until neutral, and obtain acidified montmorillonite powder, drying, and then using an aluminate coupling agent (distearoyloxyisopropyl aluminate) to modify the acidified montmorillonite powder to obtain the modified montmorillonite powder.

[0046] The preparation method of the composite powder explosion suppressing agent based on modified montmorillonite powder is as follows:

[0047] Step 1. Put the mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com