Preparation method and application of a carbon cloth in-situ structure double oxide self-supporting battery electrode material

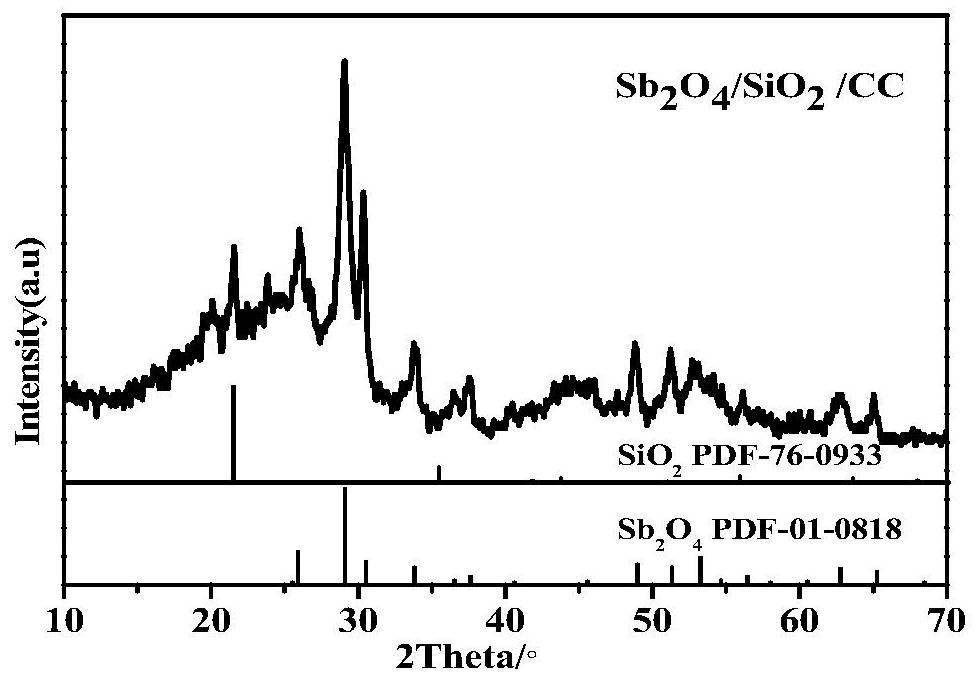

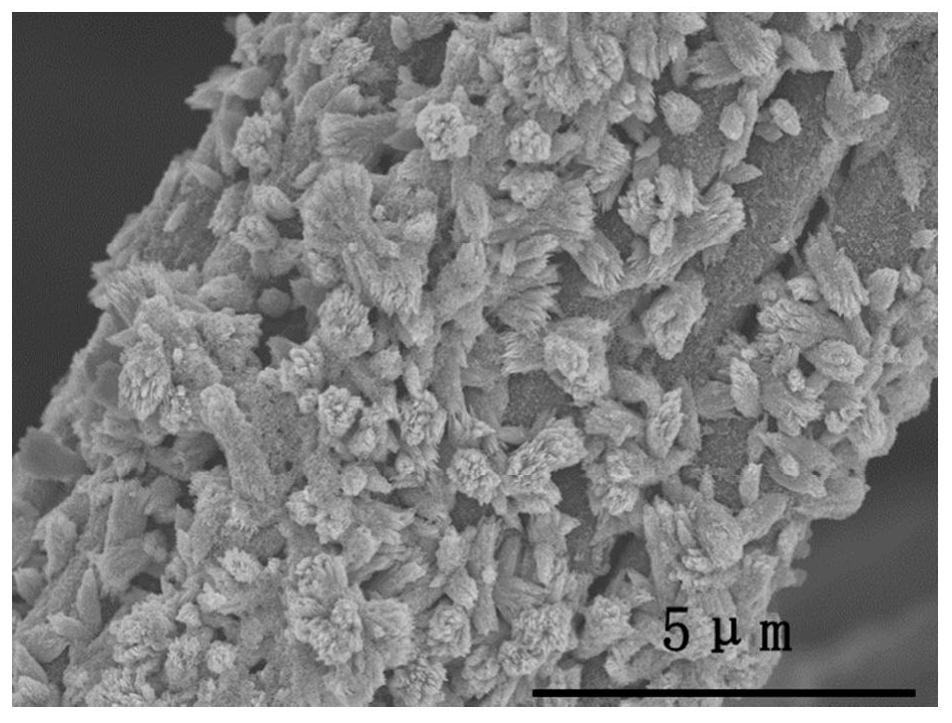

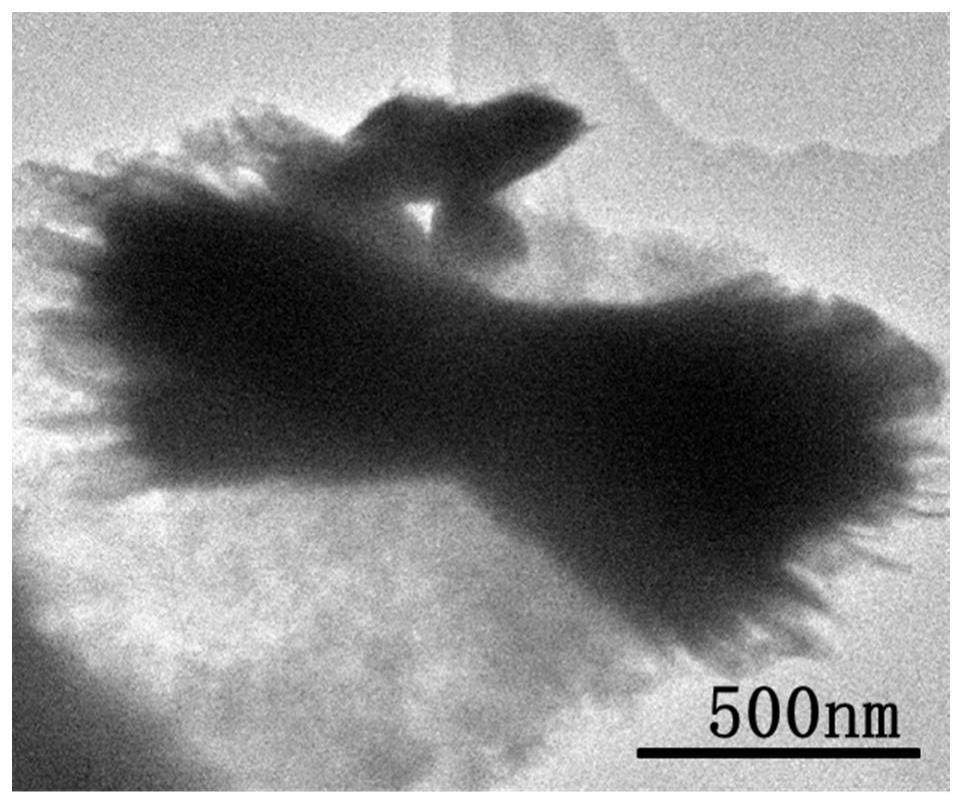

A double oxide and battery electrode technology, applied in battery electrodes, active material electrodes, nanotechnology for materials and surface science, etc., to increase the collision probability, inhibit volume expansion, and improve the electrochemical reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Take 0.31g of sodium silicate nonaqueous water and 0.57g of antimony trichloride into the reaction lined kettle, and add 40ml of deionized water at the same time and stir it with a glass rod to dissolve it;

[0034] Step 2: Arrange carbon with a size of 4cm×2cm in 20g / L ammonium dihydrogen phosphate aqueous solution. After anodizing for 3 minutes, wash it repeatedly with deionized water and absolute ethanol and arrange the dried carbon in the solution Dipping for 30min;

[0035] Step 3: Put the lid of the inner kettle into the outer kettle and fix it in the homogeneous reactor, and heat it from room temperature to 180°C for 48 hours in a rotating state;

[0036] Step 4: After the hydrothermal reaction is over, cool the reactor to room temperature naturally, then take out the cooled carbon cloth after the reaction, wash it repeatedly with ethanol and deionized water until it is clean, and keep it in an oven at 60°C for 8 hours to obtain the product The prepared ...

Embodiment 2

[0042] Step 1: Take 0.31g of sodium silicate nonaqueous water and 0.57g of antimony trichloride into the reaction lined kettle, and add 40ml of deionized water at the same time and stir it with a glass rod to dissolve it;

[0043] Step 2: Arrange carbon with a size of 4cm×2cm in 20g / L ammonium dihydrogen phosphate aqueous solution. After anodizing for 3 minutes, wash it repeatedly with deionized water and absolute ethanol and arrange the dried carbon in the solution Dipping for 30min;

[0044] Step 3: Put the buckle cover of the inner kettle into the outer kettle and fix it in the homogeneous reactor, and heat it from room temperature to 180°C under the rotating state for 72 hours of hydrothermal reaction;

[0045] Step 4: After the hydrothermal reaction is over, cool the reactor to room temperature naturally, then take out the cooled carbon cloth after the reaction, wash it repeatedly with ethanol and deionized water until it is clean, and keep it in an oven at 60°C for 12 ho...

Embodiment 3

[0048] Step 1: Take 0.16g of sodium silicate nonaqueous water and 0.3g of antimony trichloride into the reaction lined kettle, and add 20ml of deionized water at the same time and stir it with a glass rod to dissolve it;

[0049] Step 2: Arrange carbon with a size of 4cm×2cm in 20g / L ammonium dihydrogen phosphate aqueous solution. After anodizing for 5 minutes, wash it repeatedly with deionized water and absolute ethanol and arrange the dried carbon in the solution Dipping for 10min;

[0050] Step 3: Put the lid of the inner kettle into the outer kettle and fix it in the homogeneous reactor, and heat it from room temperature to 180°C for 48 hours in a rotating state;

[0051] Step 4: After the hydrothermal reaction, cool the reactor to room temperature naturally, then take out the cooled carbon cloth after the reaction, wash it repeatedly with ethanol and deionized water until it is clean, and keep it in an oven at 100°C for 4 hours to obtain the product Antimony tetraoxide / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com