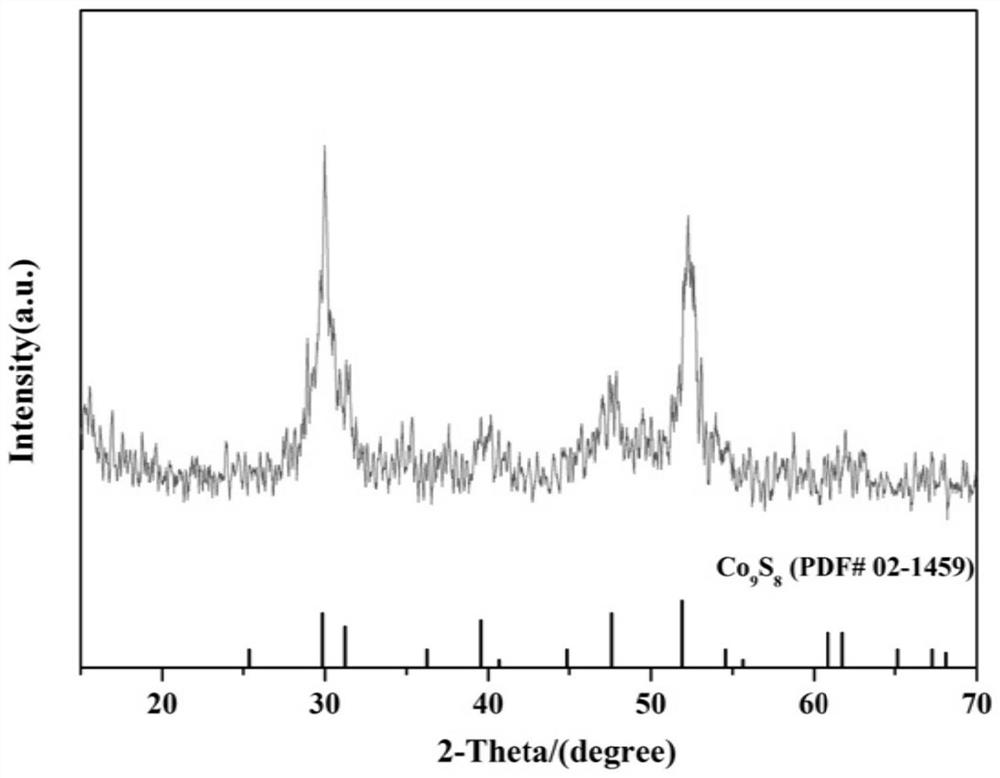

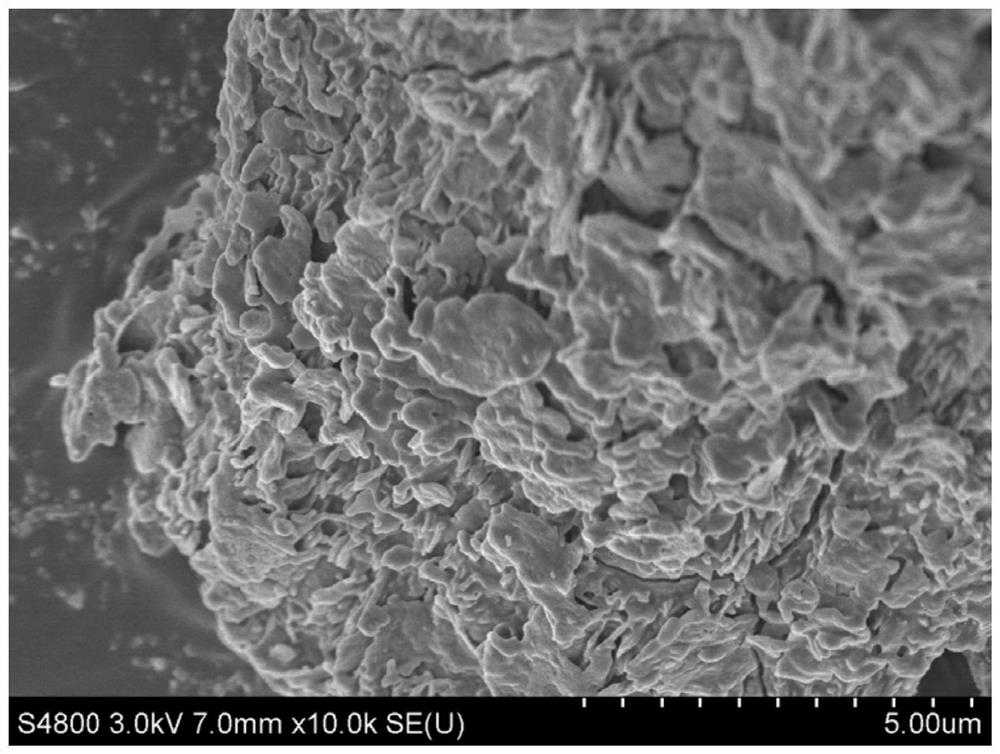

A kind of cobalt sulfide nano sheet material and preparation method thereof

A technology of cobalt sulfide and nanosheets, applied in the field of electrochemistry, to achieve short reaction time, improve charge and discharge, and reduce migration distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Take 2.0g of cobalt acetate tetrahydrate and add it to 20mL of ethylene glycol and 10mL of isopropanol mixed solution, put the above three raw materials into a beaker, and stir for 35min with magnetic stirring at a speed of 730r / min to obtain a solution A;

[0048] Step 2: Dissolve 1.0g of sodium sulfide in 30mL of deionized water, stir until the solution is clear, then add ammonia solution dropwise to the solution at a rate of 0.16mL / min, after adding one drop of ammonia solution, stir until the pH of the solution Stable, then drop the next drop of ammonia solution until the pH value of the solution is adjusted to 11.5 to obtain solution B;

[0049] Step 3: Mix the above solution B and solution A, and disperse by ultrasonic for 85 minutes; pour the mixed solution into the homogeneous hydrothermal reaction kettle according to the filling ratio of 55% and seal it, and put the inner kettle in the outer kettle and fix it Placed in a homogeneous reactor, heated fro...

Embodiment 2

[0055] Step 1: Add 1.5g of cobalt acetate tetrahydrate into 16mL of ethylene glycol and 9mL of isopropanol mixed solution, put the above three raw materials into a beaker, and stir for 30min at a speed of 700r / min using magnetic stirring to obtain a solution A;

[0056] Step 2: Dissolve 0.7g of sodium sulfide in 35mL of deionized water, stir until the solution is clear, then add ammonia solution dropwise to the solution at a rate of 0.15mL / min, after adding one drop of ammonia solution, stir until the pH of the solution Stable, then drop the next drop of ammonia solution until the pH value of the solution is adjusted to 11.2 to obtain solution B;

[0057] Step 3: Mix the above solution B and solution A, and disperse by ultrasonic for 80 minutes; pour the mixed solution into the homogeneous hydrothermal reaction kettle according to the filling ratio of 50% and seal it, and put the inner kettle in the outer kettle and fix it Place it in a homogeneous reactor, heat it from room ...

Embodiment 3

[0061] Step 1: Take 2.2g of cobalt acetate tetrahydrate and add it to 24mL of ethylene glycol and 11mL of isopropanol mixed solution, put the above three raw materials into a beaker, and use magnetic stirring to stir for 40min at a speed of 750r / min to obtain a solution A;

[0062] Step 2: Dissolve 1.2g of sodium sulfide in 50mL of deionized water, stir until the solution is clear, then add ammonia solution dropwise to the solution at a rate of 0.18mL / min, after adding one drop of ammonia solution, stir until the pH of the solution Stable, then drop the next drop of ammonia solution until the pH value of the solution is adjusted to 11.8 to obtain solution B;

[0063] Step 3: Mix the above solution B and solution A, and disperse by ultrasonic for 90 minutes; pour the mixed solution into a homogeneous hydrothermal reaction kettle with a filling ratio of 60% and seal it, and put the inner kettle in the outer kettle and fix it Placed in a homogeneous reactor, heated from room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com