A kind of silicon dioxide airgel microspheres encapsulating/releasing oily substances and preparation method thereof

A technology of silica and oily substances, which is applied in the field of silica airgel microspheres and its preparation, can solve problems such as difficult to realize, and achieve the effects of strong barrier performance, low density and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Mix 208 grams of tetraethyl orthosilicate, 50 grams of ethanol, and 10 grams of polyethylene glycol (average molecular weight 500) until transparent, then add 7.5 grams of concentrated hydrochloric acid (37% by mass) and 5 grams of Mix the ionic water evenly, after stirring for 5 minutes, raise the temperature to 70°C to continue the reaction for 4 hours, and quickly remove the solvent in the system by distillation under reduced pressure to obtain a flowable and transparent polyalkoxysiloxane prepolymer with a certain viscosity . 2) Add 50 grams of polyalkoxysiloxane prepolymer and 25 grams of hexane into 200 grams of deionized water, stir quickly to obtain a uniform white emulsion, then add 25 grams of ammonia water (mass concentration 25%), and Continue to stir for 5 hours to obtain a milky white dispersion of silica airgel microspheres wrapped in hexane; 3) Centrifuge the dispersion of airgel microspheres to remove the supernatant, wash the lower white solid with ...

Embodiment 2

[0051] The difference between Example 2 and Example 1 is that polyethylene glycol (average molecular weight 500) in step 1) is replaced by polyvinyl alcohol (average molecular weight 750), and the amounts of concentrated hydrochloric acid and deionized water are increased to 15 grams and 10 grams, replace the hexane in step 2) with octyl acetate, and replace the centrifugation-water washing operation in step 3) with funnel filtration.

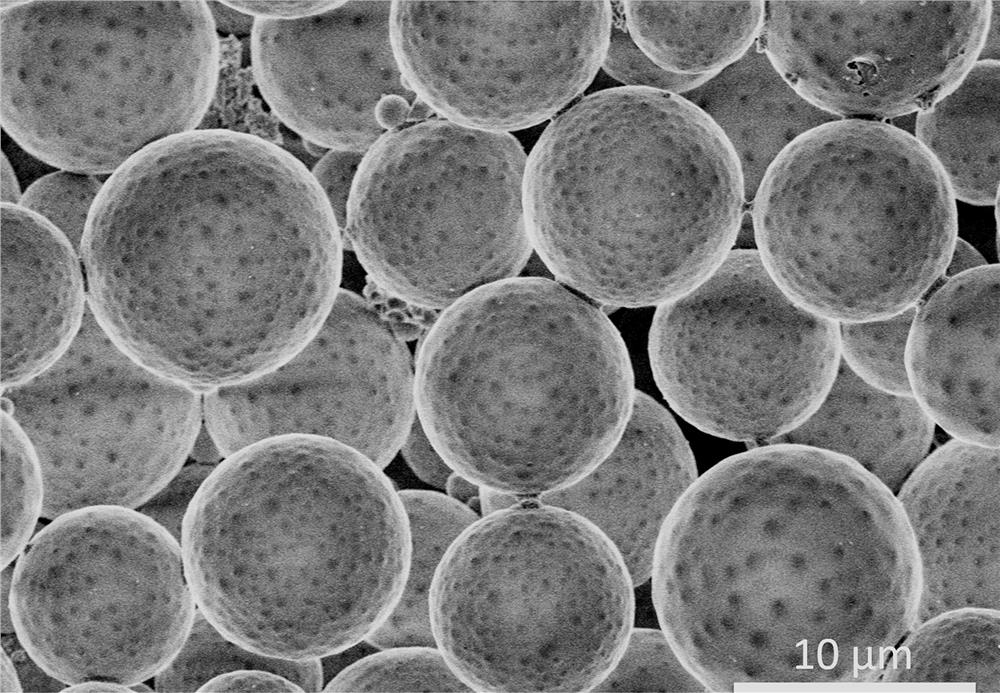

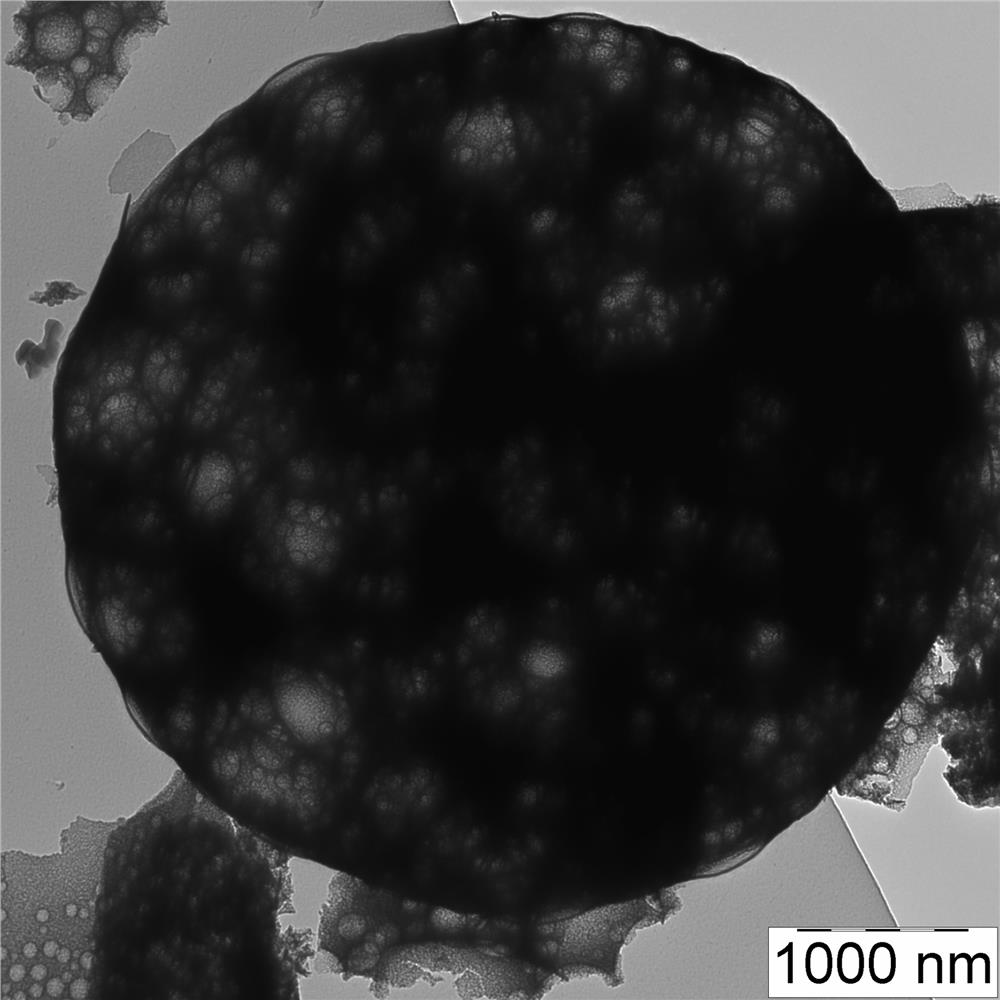

[0052] The scanning electron micrograph of the silica airgel microsphere of gained octyl acetate wrapping is as follows Figure 6 As shown, its size is in the range of 1-4 microns, the size distribution is relatively uniform, the spherical structure is complete, and the surface is airtight. Its transmission electron microscope pictures are as Figure 7 As shown, the silica framework (dark part) and the porous structure inside the microspheres (light part) can be clearly observed, and the porosity is very high, with a bulk density of 0.06 g / cm ...

Embodiment 3

[0054]The difference between embodiment 3 and embodiment 1 is that in step 1), 208 grams of tetraethyl orthosilicate is replaced by 152 grams of tetramethyl orthosilicate, ethanol is replaced by isopropanol, and polyethylene glycol is replaced by Polyethylene glycol monomethyl ether (molecular weight 500), replace 7.5 grams of concentrated hydrochloric acid (mass fraction 37%) with 7 grams of concentrated nitric acid (mass fraction 68%), replace 25 grams of hexane in step 2) with 35 grams of toluene, Replace 25 g of ammonia with 25 g of aqueous sodium hydroxide (0.1 M).

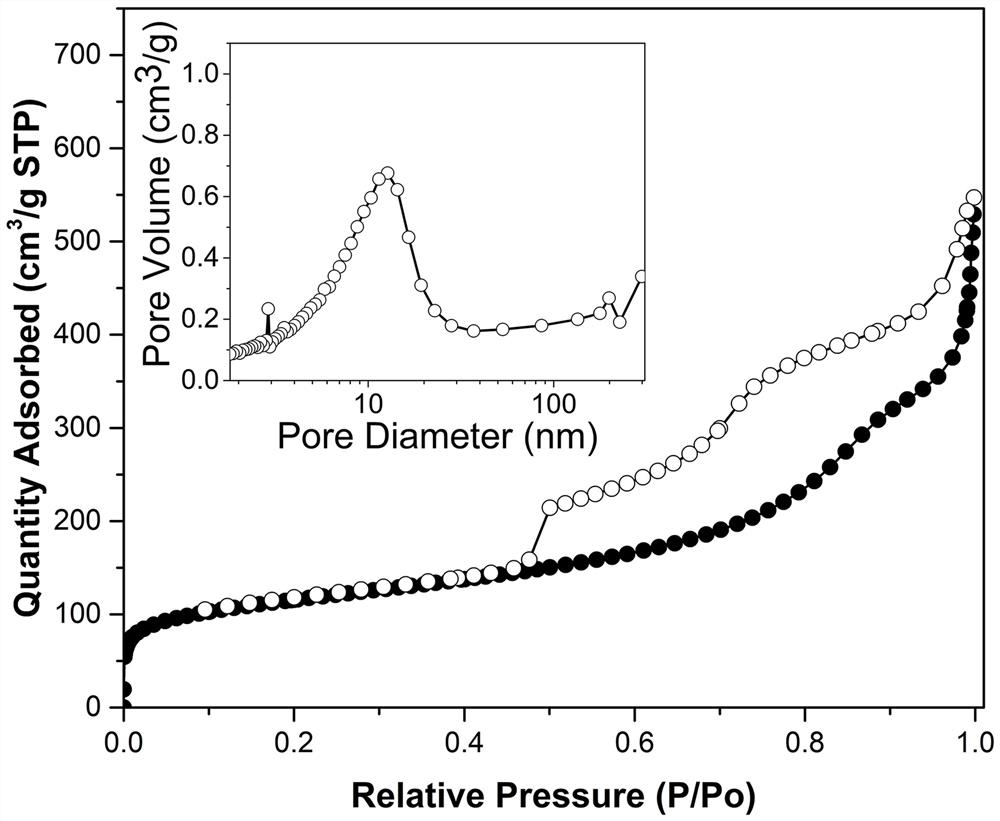

[0055] The scanning electron micrograph of the silica airgel microsphere of gained wrapping toluene is as follows Figure 11 As shown, the spherical structure of the microsphere is complete, and the size of the microsphere is about 10 microns. Bulk density 0.065 g / cm 3 , with a specific surface area of 480 m 2 / g, the pore size distribution is in the range of 2-100 nanometers, concentrated in 10 nanomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com