Manufacture method of explosion-proof aluminum-foil netted coil of fuel tank for aircraft

A manufacturing method and fuel tank technology, which are applied in the direction of fuel tank safety measures, wire mesh, and other household appliances, can solve the problems of aircraft fuel tank explosion prevention, etc., and achieve the effects of good explosion suppression effect, long service life, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

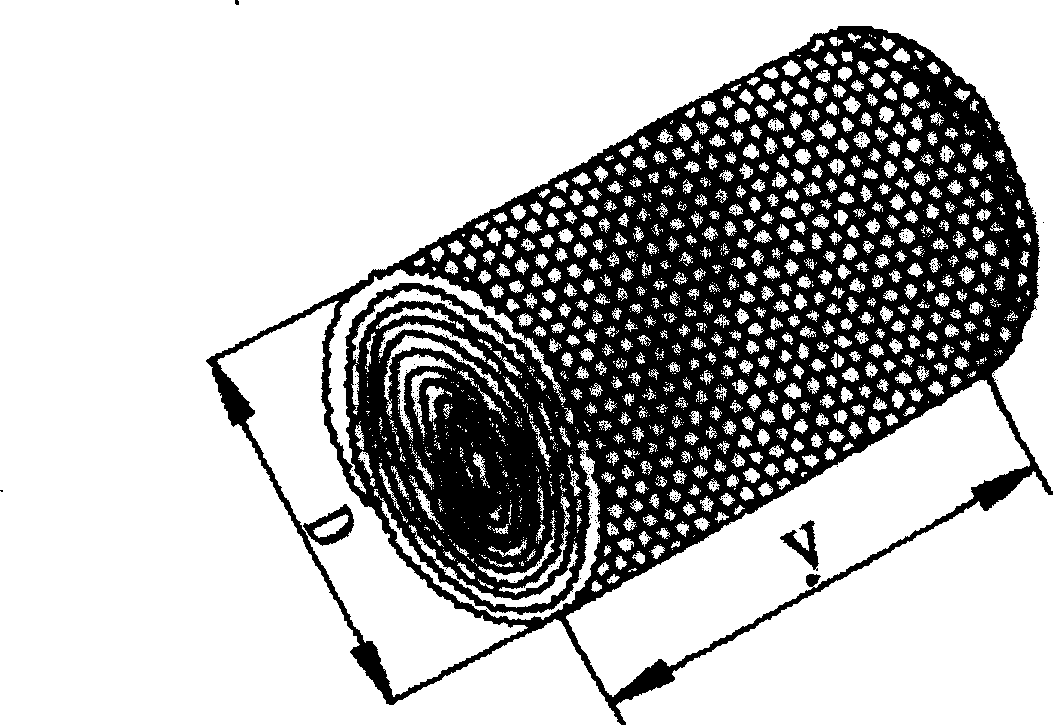

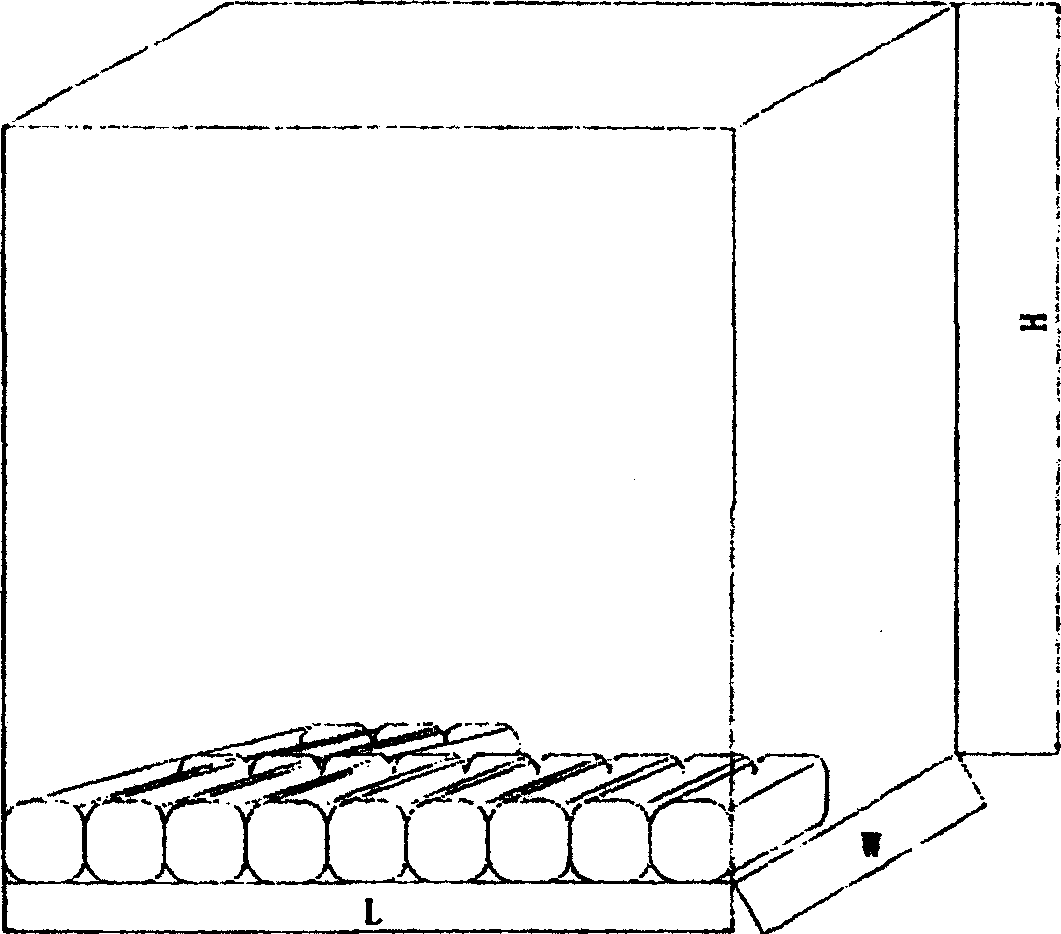

[0014] The present invention will be described in further detail below. see figure 1 , the manufacture method of explosion-proof aluminum foil net roll of aircraft fuel tank, is made of the aluminum foil net roll with honeycomb mesh, the length Y=W / n of aluminum foil net roll, W is the width of fuel tank, n is a positive integer; Aluminum foil net Equivalent diameter of roll D is the diameter of the aluminum foil mesh roll, D 当 =L / m, L is the length of the fuel tank, m is a positive integer, μ=λ 1 / λ,λ 1 is the density of the aluminum foil mesh roll, and λ is the packing density of the aluminum foil mesh roll in the fuel tank; the aluminum foil thickness δ=0.03~0.08mm used to manufacture the aluminum foil mesh is characterized in that the manufacturing steps are as follows:

[0015] (1) Determine the size of the aluminum foil mesh roll; calculate and determine the length Y and equivalent diameter D of the aluminum foil mesh roll according to the width, height and select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com