Nonmetal separating explosion suppression ball

A kind of anti-explosion ball and non-metallic technology, which is applied in the field of barrier and anti-explosion to achieve the effect of avoiding explosion accidents, high stability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

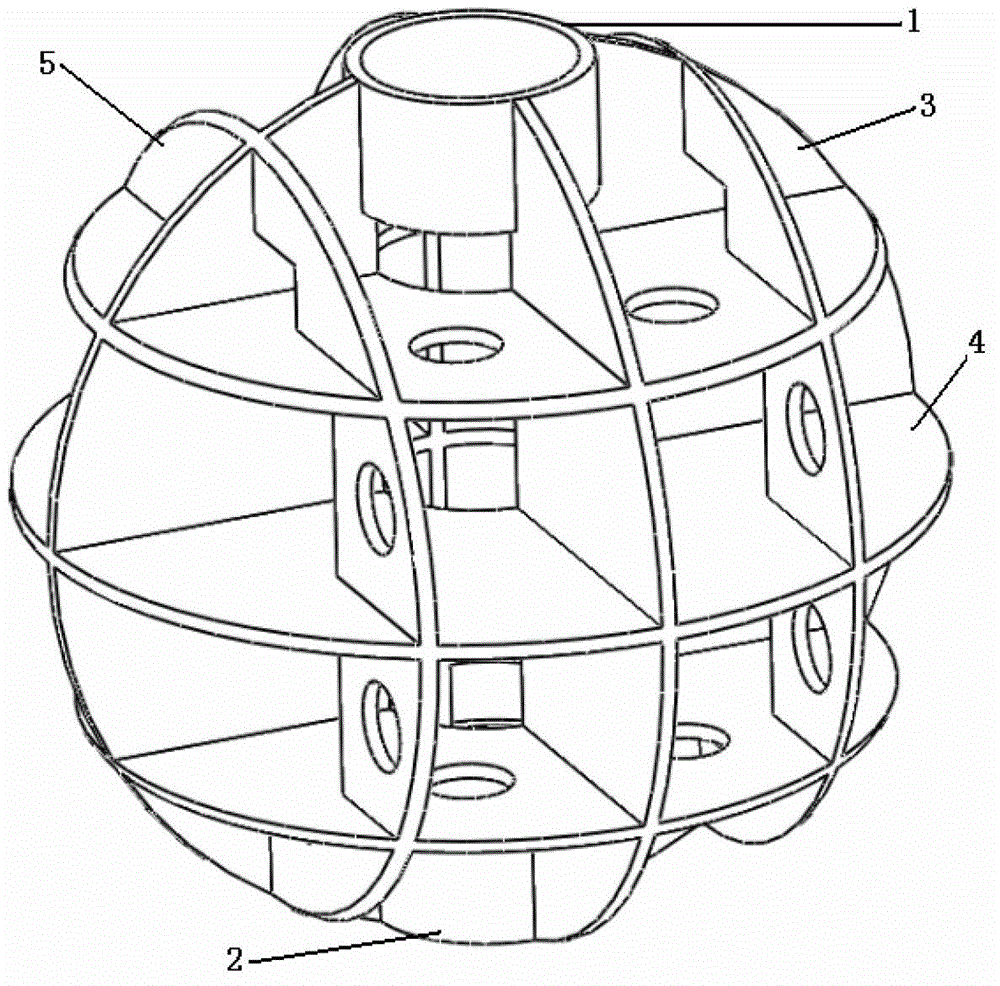

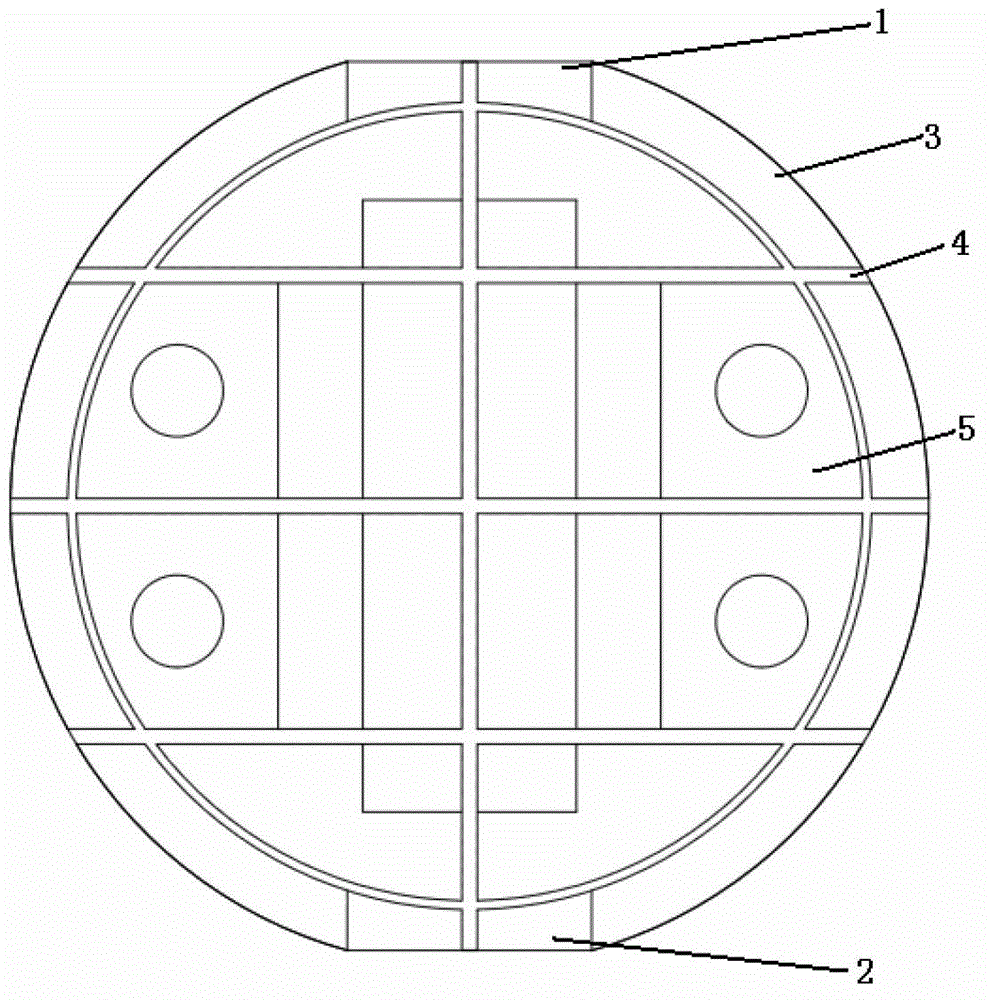

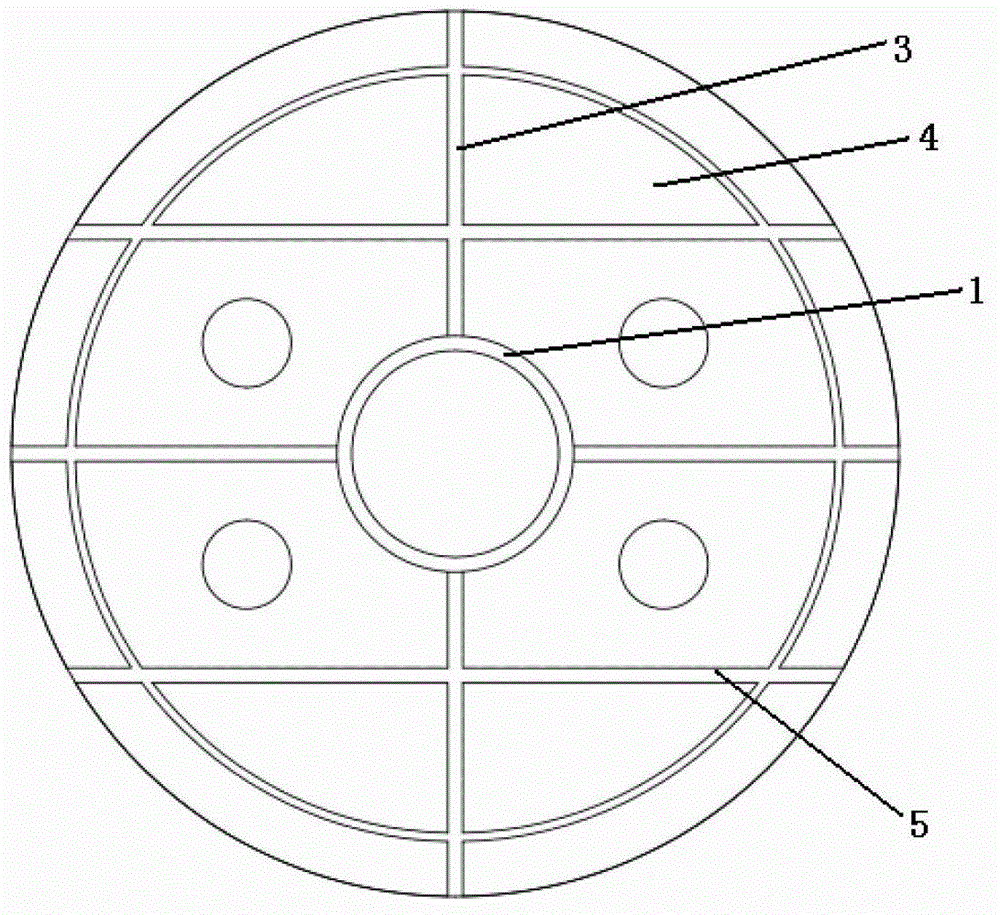

[0044] As shown in the accompanying drawings, a non-metallic blocking explosion suppression ball includes: an upper tubular structure 1, a lower tubular structure 2, an arcuate sheet 3, an annular sheet 4 and a circular sheet 5, an upper tubular structure 1, a lower tubular structure 2, an arcuate sheet Sheet 3, annular sheet 4 and circular sheet 5 form a hollow grid-shaped sphere;

[0045] The upper tubular structure 1 and the lower tubular structure 2 are respectively arranged at the upper and lower ends of the sphere and are coaxial with the sphere;

[0046] The number of the arcuate pieces 3 is four, which are symmetrically arranged around the upper tubular structure 1 and the lower tubular structure 2, the two adjacent arcuate pieces are perpendicular to each other, and the chords of the arcuate pieces 3 are The structure 2 is fixedly connected, and the arc of the arcuate piece 3 constitutes the warp of the sphere;

[0047] The number of the annular sheets 4 is four, and...

Embodiment 2

[0057] Same as Example 1, the difference is only:

[0058] The composition of the explosion-suppressed sphere material includes the following components:

[0059]

Embodiment 3

[0061] The sphere structure is the same as in Example 1,

[0062] The composition of the explosion-suppressed sphere material includes the following components and weight percentages:

[0063]

[0064] Weigh each component according to the above weight percentage, mix antioxidant, carbon black and nylon 66 masterbatch in a high-speed mixer for 3 minutes, then put it into a twin-screw extruder together with carbon fiber for granulation, and carbon fiber is extruded by extruding The auxiliary feeding port of the machine is added. The twin screw adopts SHF-30 type produced by Nanjing Jiente Electromechanical Co., Ltd. The speed of the screw machine is 450 rpm, and the temperature of each section of the extruder is controlled as follows: the barrel temperature is 240 °C in the first zone, 245 °C in the second zone, 260 °C in the third zone, 265 °C in the fourth zone, 265 °C in the fifth zone, and 265 °C in the die head. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com