Compound explosive suppressant and preparation method thereof for inhibiting explosion of low-concentration coalbed methane

A composite type, coalbed methane technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of poor explosion suppression performance and low explosion suppression efficiency, achieve good heat insulation effect, reduce heat radiation, and improve Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

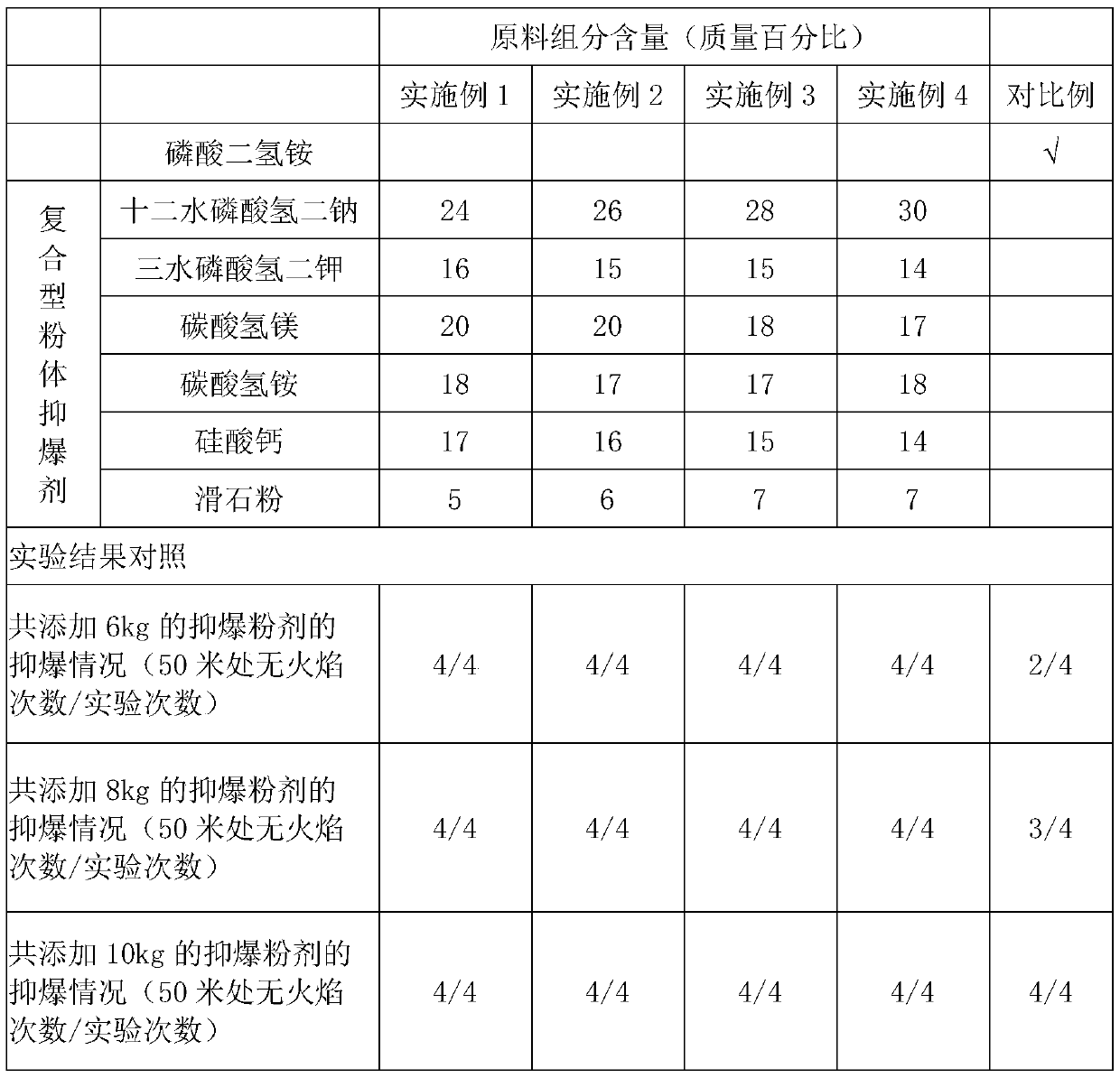

Embodiment 1

[0047] The raw material formula of the composite antiknock agent for suppressing the explosion of low-concentration coalbed methane is: by weight, 24 parts of disodium hydrogen phosphate dodecahydrate, 16 parts of dipotassium hydrogen phosphate trihydrate, 20 parts of magnesium hydrogen carbonate, hydrogen carbonate 18 parts of ammonium, 17 parts of calcium silicate, 5 parts of talcum powder.

[0048] The specific steps of the preparation method are:

[0049] The first step, the raw materials disodium hydrogen phosphate dodecahydrate, dipotassium hydrogen phosphate trihydrate, magnesium bicarbonate, ammonium bicarbonate and calcium silicate are respectively ground into powder;

[0050] In the second step, pass the talc powder and the powder ground in the first step through a 200-mesh sieve, collect the sieved powder, and set aside, and add the unsifted powder and the raw material with a particle size greater than 75 μm to the milling powder respectively. machine for grinding;...

Embodiment 2

[0056] The raw material formula of the composite antiknock agent for suppressing the explosion of low-concentration coalbed methane is: by weight, 26 parts of disodium hydrogen phosphate dodecahydrate, 15 parts of dipotassium hydrogen phosphate trihydrate, 20 parts of magnesium bicarbonate, hydrogen carbonate Ammonium 17 parts, calcium silicate 16 parts, talcum powder 6 parts.

[0057] The preparation method is the same as in Example 1.

[0058] The using method of composite antiknock agent is the same as embodiment 1.

Embodiment 3

[0060] The raw material formula of the composite antiknock agent for suppressing the explosion of low-concentration coalbed methane is: by weight, 28 parts of disodium hydrogen phosphate dodecahydrate, 15 parts of dipotassium hydrogen phosphate trihydrate, 18 parts of magnesium bicarbonate, hydrogen carbonate Ammonium 17 parts, calcium silicate 15 parts, talcum powder 7 parts.

[0061] The preparation method is the same as in Example 1.

[0062] The using method of composite antiknock agent is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com