A kind of preparation method of hydroxamate collector

A hydroxamate and collector technology, which is applied in the field of mineral flotation collector preparation, can solve the problems that the influence of the environment cannot be ignored, the inconvenience of direct granulation, and large dust pollution, so as to eliminate pollution and shorten the reaction time , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

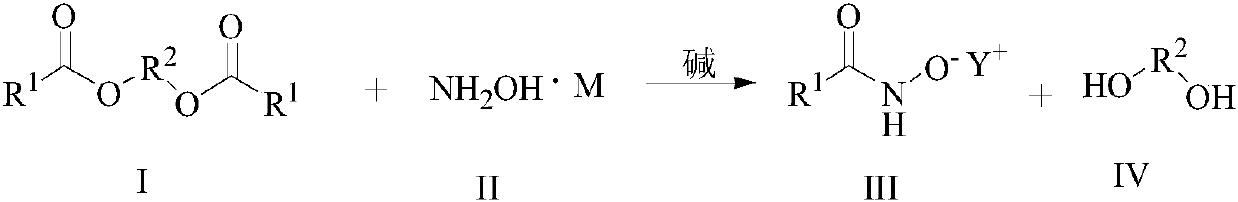

Method used

Image

Examples

Embodiment 1

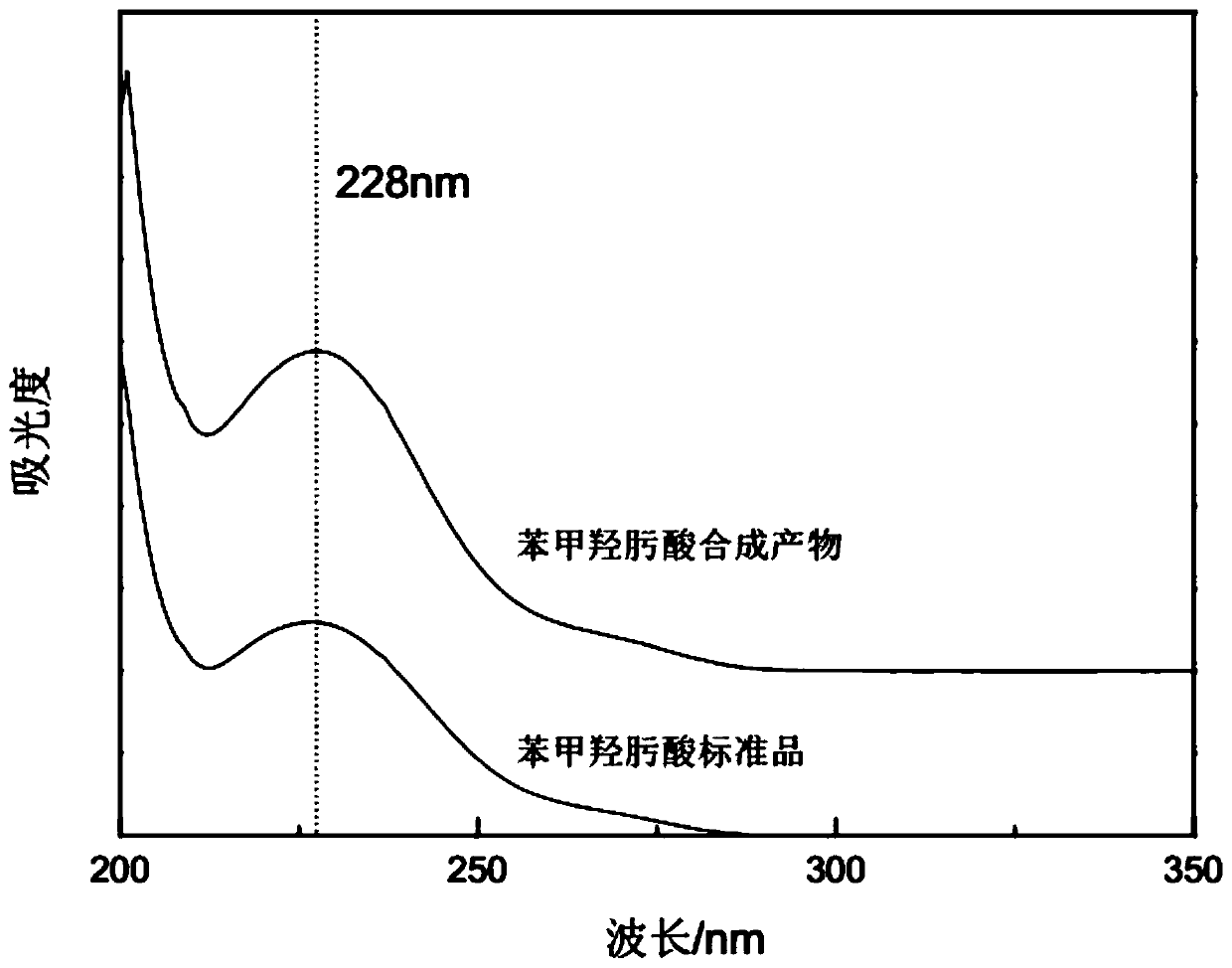

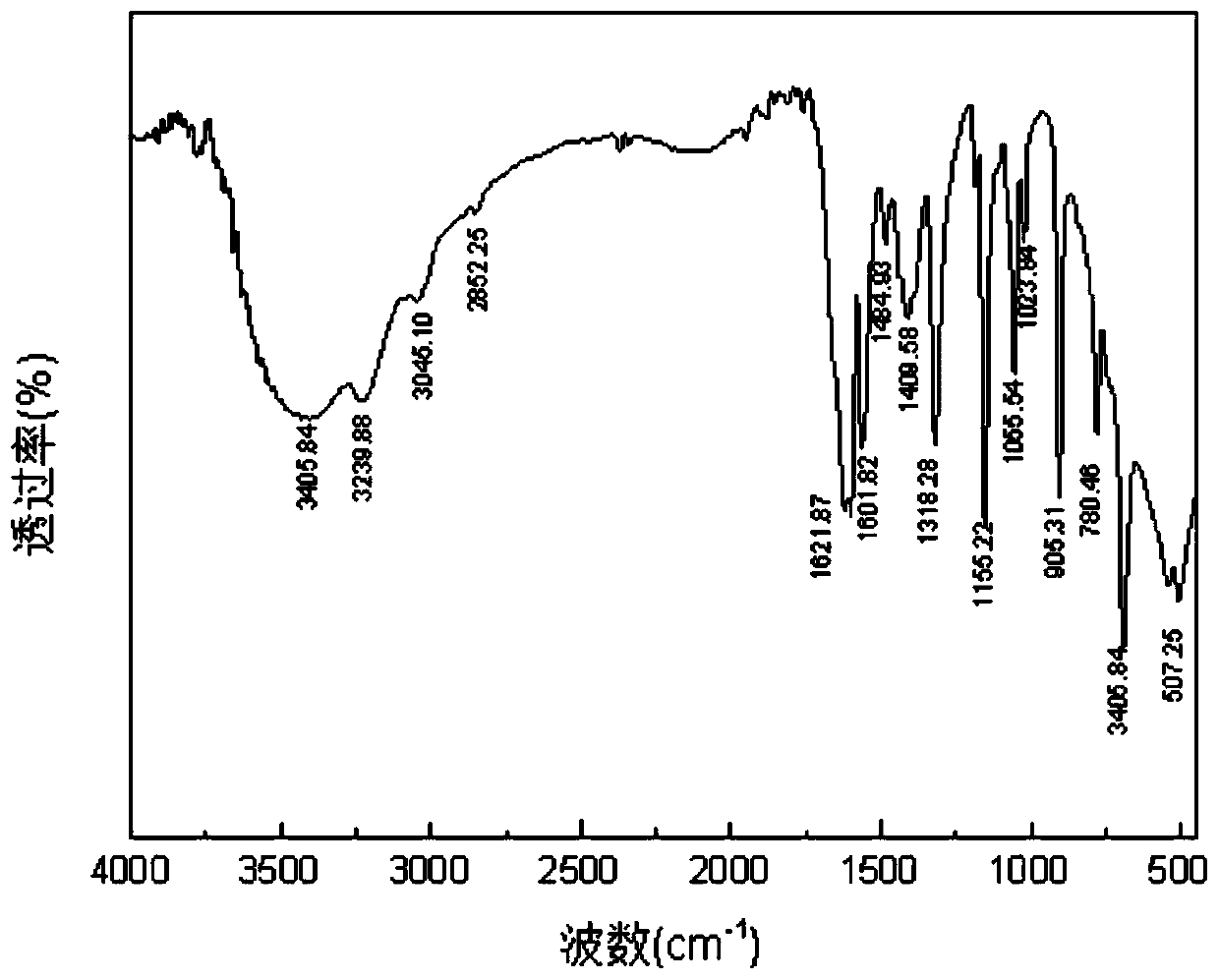

[0055] Taking 0.5mol diethylene glycol dibenzoate as a benchmark, put analytically pure diethylene glycol dibenzoate, hydroxylamine hydrochloride and sodium hydroxide in a molar ratio of 1:2.6:5.0 into SM-0.5L type agitating ball mill in turn, and stir The speed is 800r / min, react at the initial temperature of 32°C for 30min, and press the white solid product after the reaction on a 769YP-15A powder tablet press to obtain Φ5×8(mm) sodium benzohydroxamic acid particles. The yield of sodium benzohydroxamic acid was 86.41%. After acidifying the product, the UV spectrum was measured as figure 1 Shown; The product is directly measured by infrared spectrum as figure 2 shown.

Embodiment 2

[0057] Taking 1.0mol diethylene glycol dibenzoate as a benchmark, put technical grade diethylene glycol dibenzoate, hydroxylamine hydrochloride and sodium hydroxide into a WZM three-roller ball mill in a molar ratio of 1: 2.6: 5.0, and the stirring speed is 1400r / min, react at an initial temperature of 32°C for 40min, and press the white solid product after reaction on a 769YP-15A powder tablet press to obtain Φ5×8(mm) sodium benzohydroxamate particles. The yield of sodium benzohydroxamate was 80.21%.

Embodiment 3

[0059] Based on 0.05mol diethylene glycol dibenzoate, put analytically pure diethylene glycol dibenzoate, hydroxylamine hydrochloride and sodium hydroxide into the mortar in a molar ratio of 1:2.6:5.0, and start at 33°C Under high temperature, manually grind and react for 15 minutes, and press the white solid product after the reaction on a 769YP-15A powder tablet press to obtain Φ5×8 (mm) sodium benzohydroxamate particles. The yield of sodium benzohydroxamate was 88.91%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com