Nanometer hydroxyapatite/natural polymer composite, preparation method and application thereof

A nano-hydroxyapatite and natural polymer technology, applied in the field of preparation of nano-hydroxyapatite, can solve the problems of high inorganic mineral content, unsatisfactory bone tissue engineering scaffold materials, etc., and achieve low cost and simple operation process Viable, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

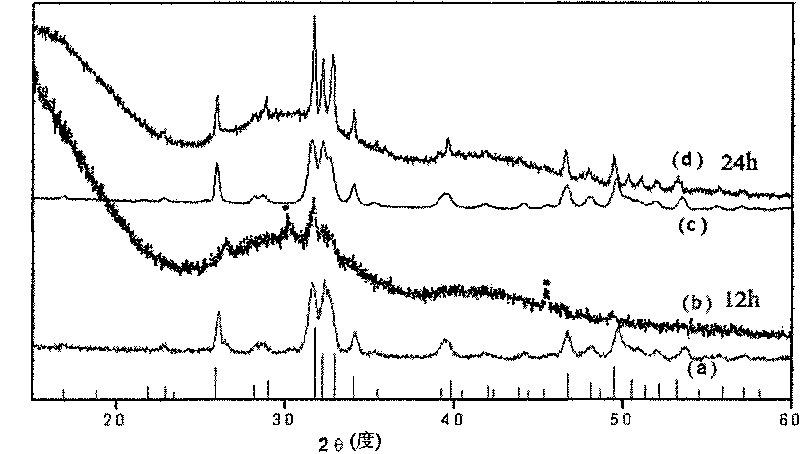

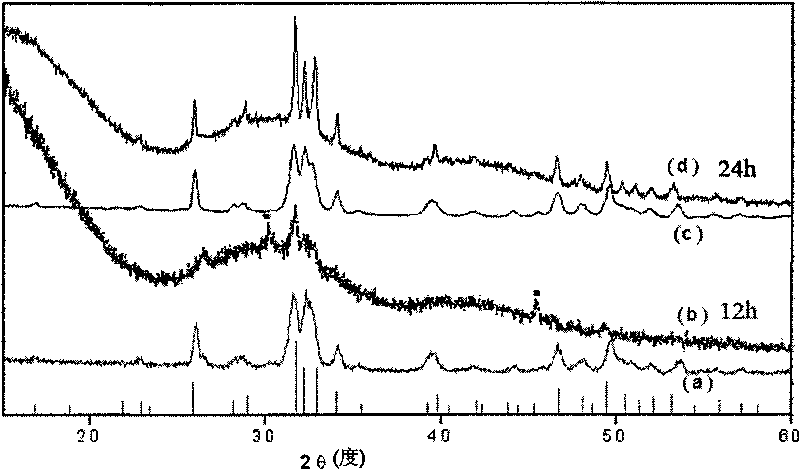

Embodiment 1

[0038] Mineralization of Chitosan Porous Sponge. The porous chitosan sponge is prepared by freeze-drying 2% (weight) chitosan acetic acid solution at -20° C. for 8 hours. The size of the sponge is 2×2×1 cm, the porosity is about 80%, and the average pore diameter is about 300 μm. Add 5ml of deionized water, 15ml of ethanol and 0.3g of urea into a jar and stir evenly, then add 5ml of sodium dihydrogen phosphate solution (0.1M). Immerse the chitosan sponge in the mixed solution and stir at a low speed for 10 minutes; make the solution fully penetrate into the sponge network, then add 8.35ml calcium chloride solution (0.1M) and continue to stir for 5 minutes, adjust the wide mouth with saturated sodium hydroxide solution The pH value of the reaction system in the bottle was 12. Seal the jar and place it in an oven at 80°C for 24 hours. The chitosan porous sponge after mineralization is fully cleaned with 85% (weight) ethanol aqueous solution, ultrasonic (40KHz) concussion 10min...

Embodiment 2

[0042] Mineralization of phosphorylated chitosan porous scaffolds. Phosphorylated chitosan porous scaffold is made by printing 2% (weight) chitosan acetic acid solution with a three-dimensional printer, and then modifying the phosphorylated surface. It is cylindrical, with a diameter of 1 cm × height of 1 cm, a porosity of 50%, and a pore size of 500 μm; Five phosphorylated chitosan porous scaffolds were placed in a reaction system containing 10ml water, 30ml ethanol and 0.5g urea. Then 10 ml of sodium dihydrogen phosphate solution (0.1 M) and 16.7 ml of calcium chloride solution (0.1 M) were added. After stirring for 5 minutes, the pH value of the system was adjusted to 10 by solid sodium hydroxide. The reaction system was sealed and placed in an oven at 70°C for 24 hours to react. The mineralized scaffold was a nano-hydroxyapatite / phosphorylated chitosan composite material. The mineralized scaffold was fully washed with water, oscillated by ultrasonic (40 KHz) for 10 min, ...

Embodiment 3

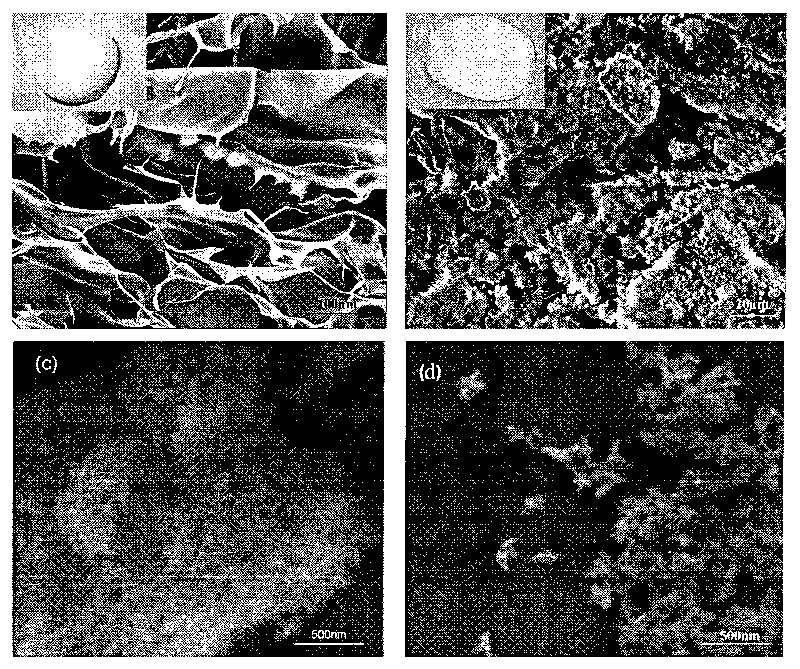

[0044] Mineralization of silk protein fiber bundles. The silk protein fiber bundle is prepared by electrospinning, the fiber diameter is less than 1 nm, and the fiber bundle diameter is about 20 μm. Place 0.1g of silk protein fiber bundles in a mixed solution containing 5ml of water, 15ml of ethanol and 0.3g of urea, and vibrate on a shaker at a speed of 60rpm. Then add 8.35ml of calcium chloride solution (0.05M) and 5ml of sodium dihydrogen phosphate solution (0.05M), and adjust the pH value of the system to 12 with saturated sodium hydroxide solution. Seal the reaction system and place it in an oven at 60° C. for 8 hours to obtain a nano-hydroxyapatite / silk protein composite material. The mineralized sponge was fully washed with water, oscillated by ultrasonic (20KHz) for 5min, then frozen at -20°C for 2h, and then freeze-dried. Transmission electron microscopy and scanning electron microscopy of the mineralized material show that the surface of the fiber is tightly covere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com