Method for producing battery grade iron phosphate

A production method and technology of iron phosphate, applied in the direction of battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of high manufacturing difficulty, high production difficulty, and high cost, and achieve the goals of reducing production costs, improving purity, and saving production materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) the following is the implementation process that adopts the inventive method to obtain ferric phosphate:

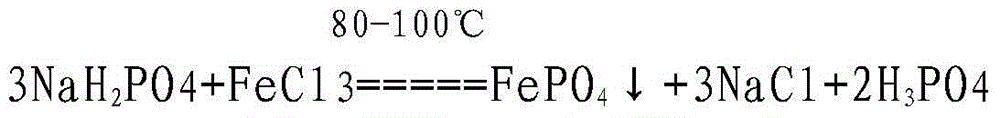

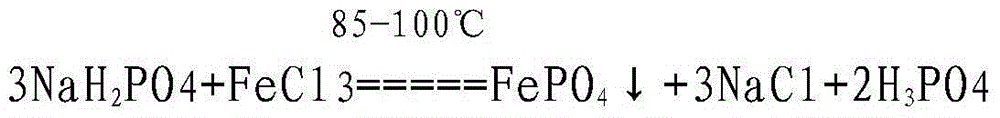

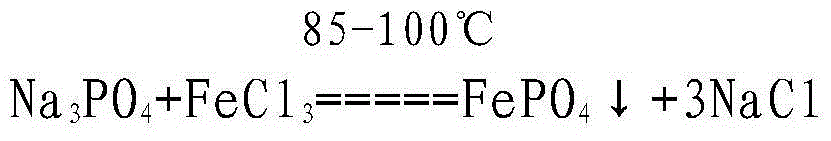

[0017] Add 300KG-600KG of 30-40% ferric chloride solution with a purity greater than 98% in a 3000L reactor, then add 1000L of pure water, then heat up to 85-100°C and keep warm, after that, Slowly add 20-30% monosodium phosphate solution with a purity greater than 99%. The amount of monosodium phosphate added is 3-3.5 times the molar amount of ferric chloride, and the addition time is controlled within 1-2 hours. After the addition of the materials is completed, After 20-60 minutes of heat preservation reaction, the slurry is obtained, and the slurry is subjected to centrifugation to obtain solid and mother liquor. The solid is added to a 1000L reaction kettle, and then 800L of pure water is added to stir for 30-60 minutes, and then centrifuged to obtain The solids were repeatedly washed 4 times according to the above steps, and finally dried and sieved to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com