Curing agent for lead-contaminated soil remediation and remediation method

A technology for lead-contaminated soil and a remediation method is applied in the field of curing agent and remediation for lead-contaminated soil remediation, which can solve the problems of inability to completely eradicate lead elements on the soil surface, short hyperaccumulation plants, and long growth cycles, and achieve a good curing effect. , The effect of good adjustment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

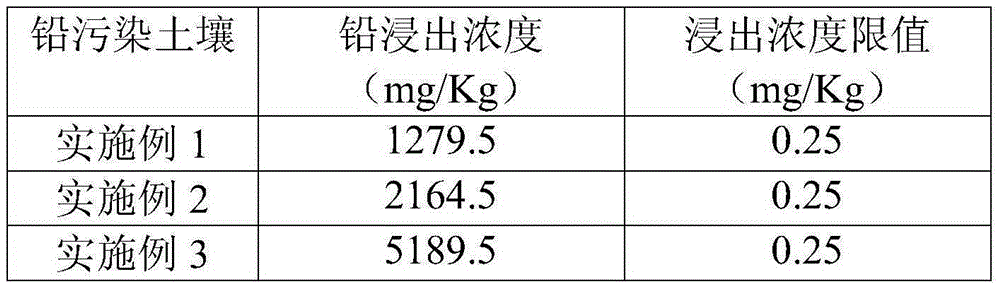

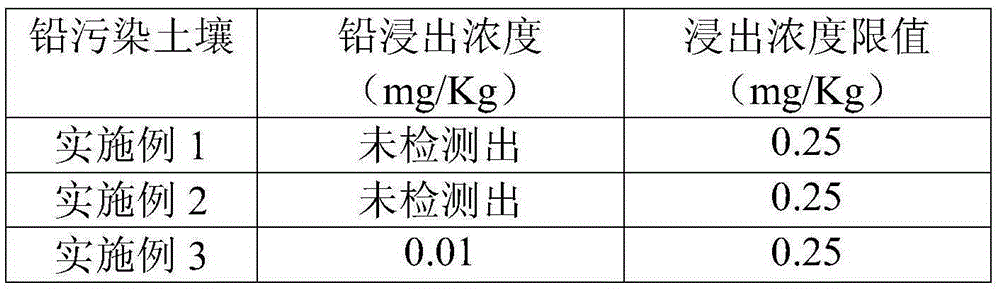

Embodiment 1

[0036] A method for remediation of lead-contaminated soil, which includes the following steps:

[0037] A. Treatment of lead-contaminated soil

[0038] First, excavate the lead-contaminated soil that needs to be repaired at a depth of 35cm, and transfer the soil to a special site for soil repair;

[0039] B. Preparation of curing agent

[0040] Mix 3 parts of Portland cement and 1 part of quicklime evenly to obtain curing agent powder;

[0041] Weigh 1 part of sodium dihydrogen phosphate, then add water in a ratio of 1:2 by mass ratio of solid to liquid, and stir until the sodium dihydrogen phosphate is completely dissolved to obtain a curing agent liquid, which is prepared for ready use ;

[0042] C, curing repair

[0043] First, mix the curing agent powder prepared in step B with 100 parts of lead-contaminated soil uniformly, then gradually add the curing agent liquid prepared in step B, and continue to mix during the process of adding the curing agent liquid to make it fully mixed wit...

Embodiment 2

[0045] A method for remediation of lead-contaminated soil, which includes the following steps:

[0046] A. Treatment of lead-contaminated soil

[0047] First, excavate the lead-contaminated soil that needs to be repaired at a depth of 30cm, and transfer the soil to a special site for soil repair;

[0048] B. Preparation of curing agent

[0049] Mix 3 parts of Portland cement and 2 parts of quicklime evenly to obtain curing agent powder;

[0050] Weigh 1.5 parts of sodium dihydrogen phosphate, then add water in a ratio of 1:2 by mass ratio of solid to liquid, and stir until the sodium dihydrogen phosphate is completely dissolved to obtain a curing agent liquid. The curing agent liquid is ready for use ;

[0051] C, curing repair

[0052] First, mix the curing agent powder prepared in step B with 100 parts of lead-contaminated soil uniformly, then gradually add the curing agent liquid prepared in step B, and continue to mix during the process of adding the curing agent liquid to make it fu...

Embodiment 3

[0054] A method for remediation of lead-contaminated soil, which includes the following steps:

[0055] A. Treatment of lead-contaminated soil

[0056] First, excavate the lead-contaminated soil that needs to be repaired at a depth of 40cm, and transfer the soil to a special site for soil repair;

[0057] B. Preparation of curing agent

[0058] Mix 5 parts of Portland cement and 2 parts of quicklime evenly to obtain curing agent powder;

[0059] Weigh 2 parts of sodium dihydrogen phosphate, then add water in a ratio of 1:2 by mass ratio of solid to liquid, and stir until the sodium dihydrogen phosphate is completely dissolved to obtain a curing agent liquid. The curing agent liquid is ready for use ;

[0060] C, curing repair

[0061] First, mix the curing agent powder prepared in step B with 100 parts of lead-contaminated soil uniformly, then gradually add the curing agent liquid prepared in step B, and continue to mix during the process of adding the curing agent liquid to make it full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com