Patents

Literature

33results about How to "Resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for transmitting data on unlicensed band and base station therefor

ActiveUS20170215082A1Efficiently manageResource utilizationNetwork traffic/resource managementAssess restrictionFrequency bandUnlicensed band

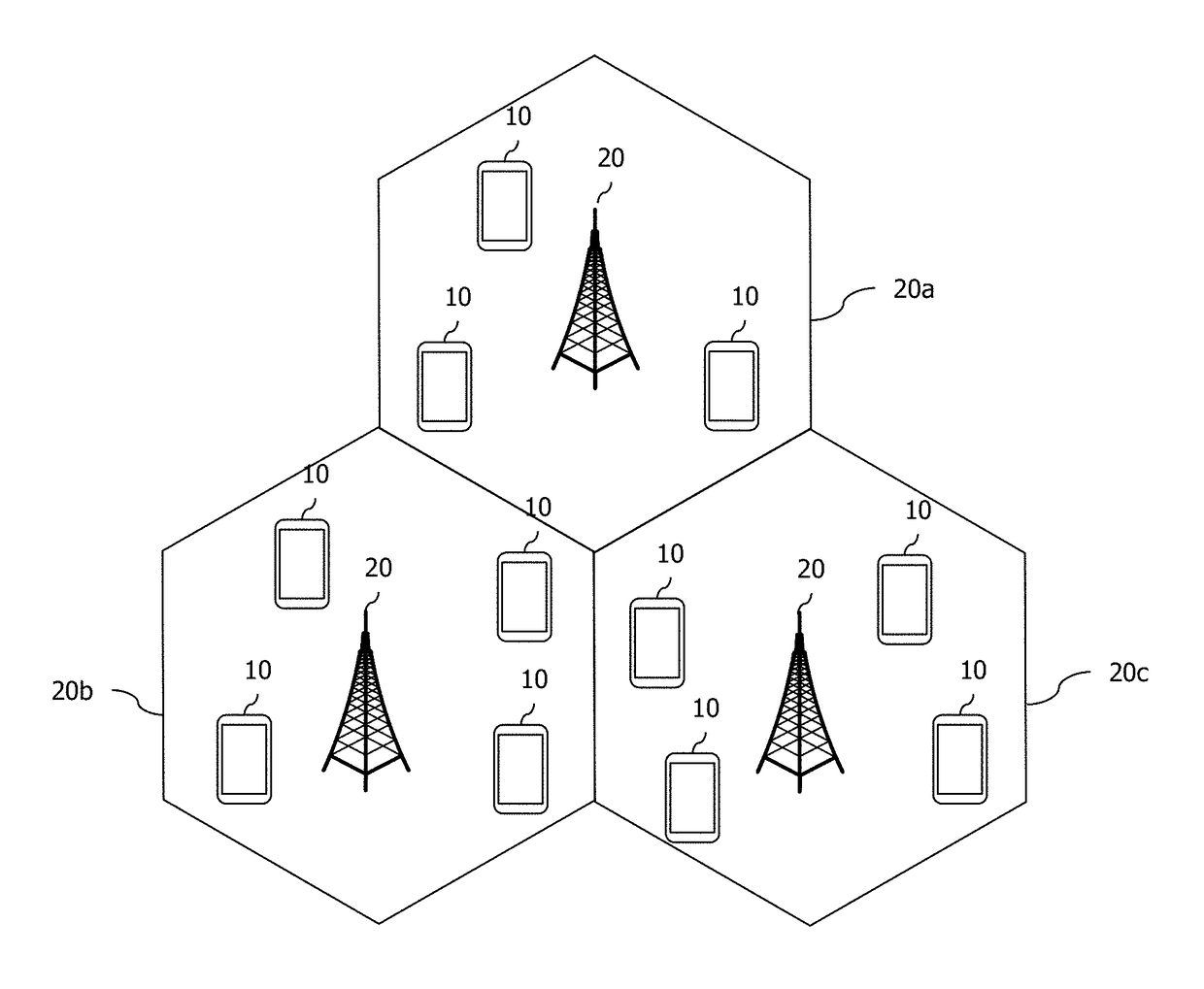

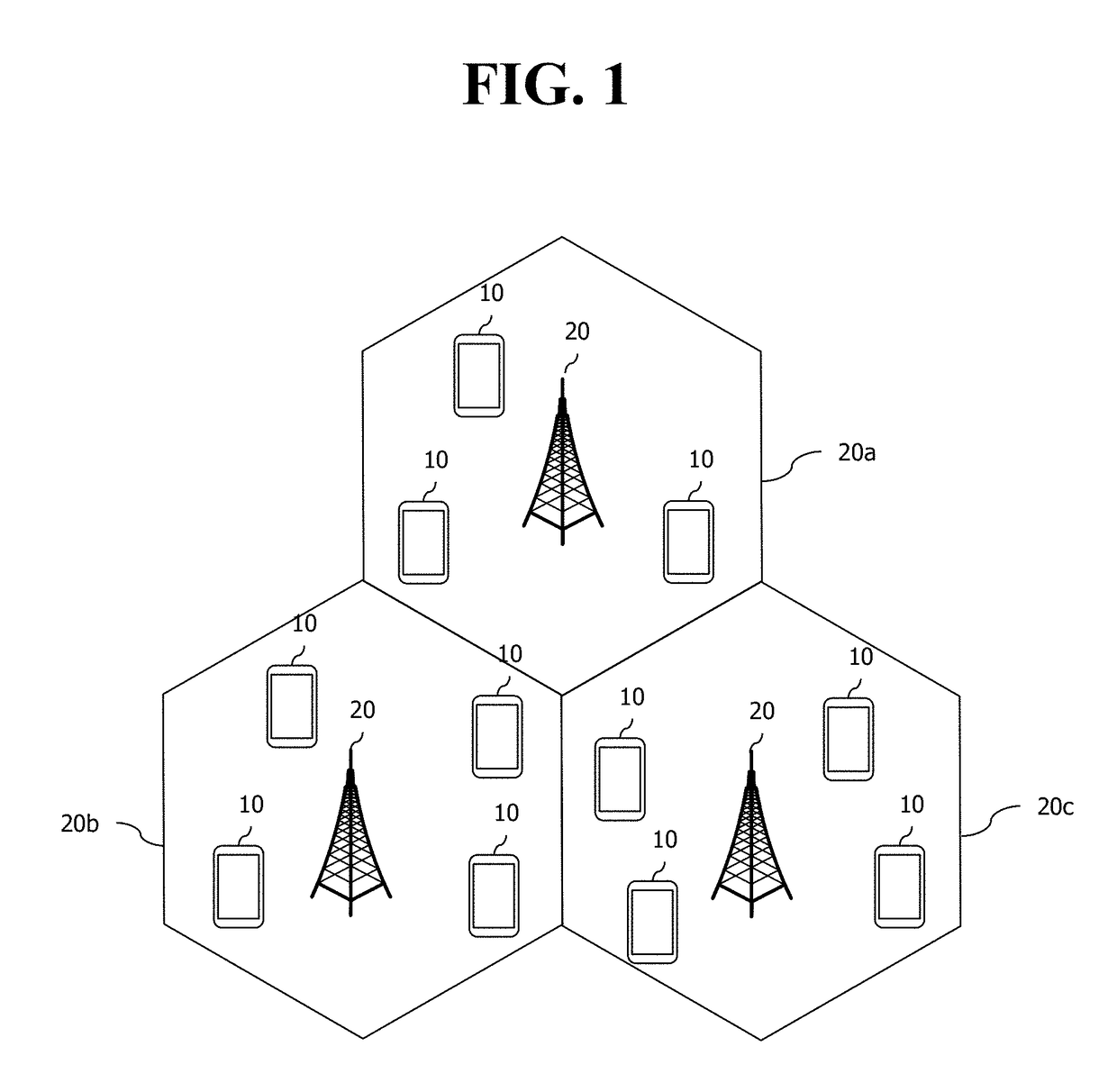

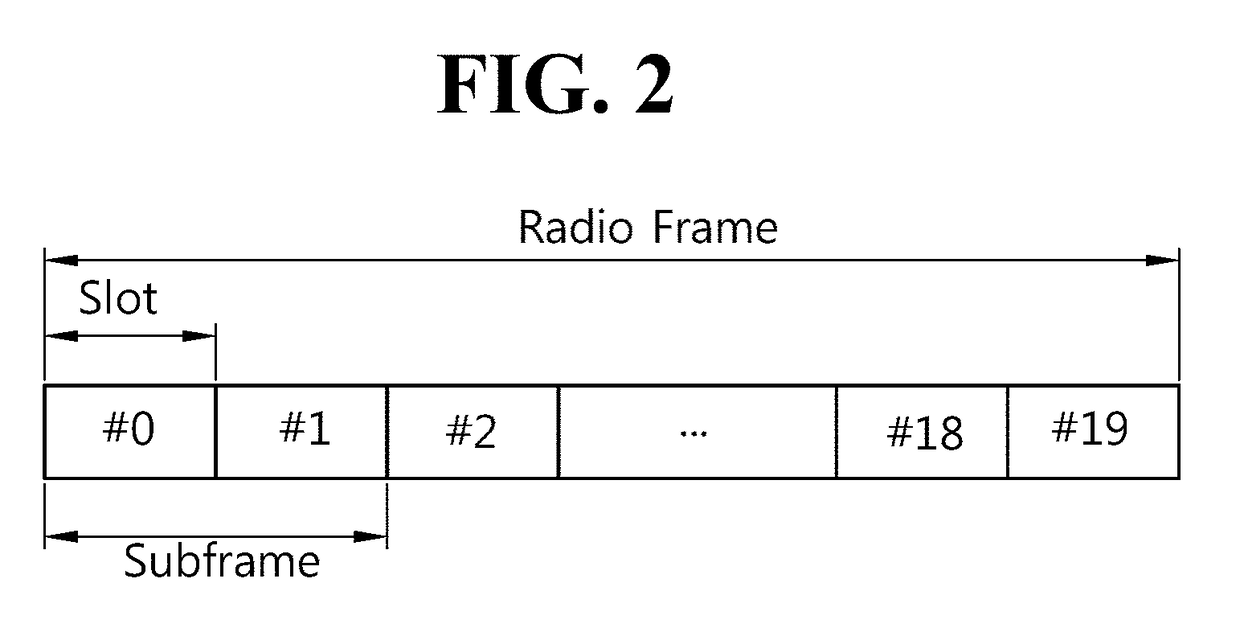

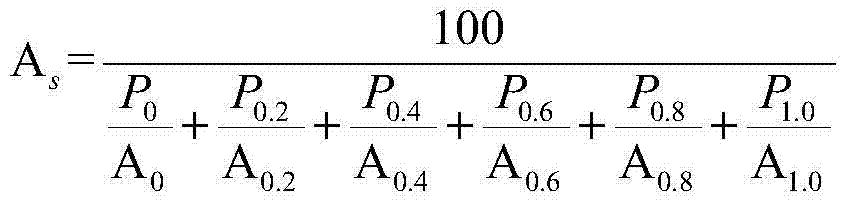

One disclosure of the present specification provides a method by which a long term evolution advanced (LTE-A)-based base station transmits data on an unlicensed band. The method can comprise the steps of: setting, by the base station, a listen before talk (LBT) configuration for determining whether to transmit signals of other nodes before transmitting data on the unlicensed band; measuring, by the base station, interference due to signals from other nodes during a preset measurement period; comparing the detected interference and a preset threshold value; changing the LBT configuration according to the comparison; and transmitting the changed LBT configuration to a terminal.

Owner:LG ELECTRONICS INC

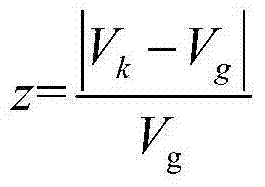

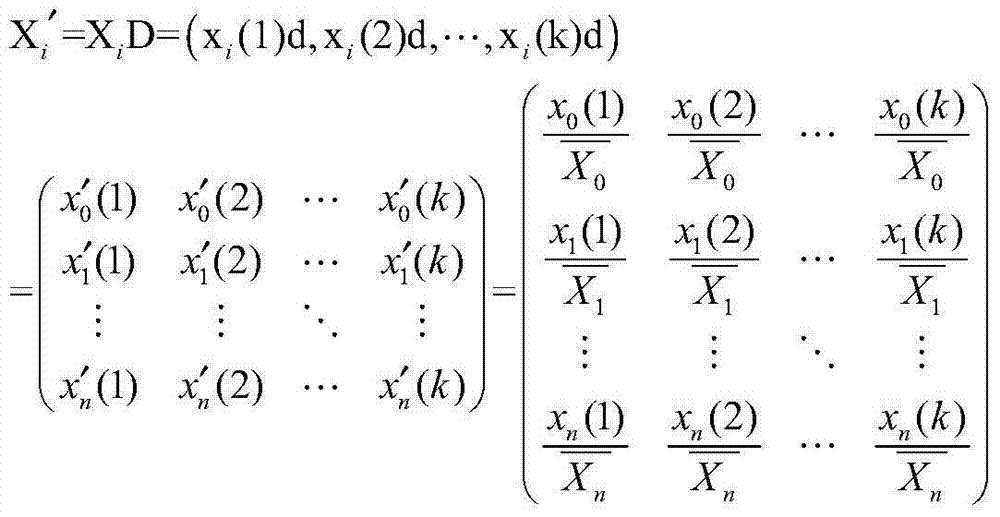

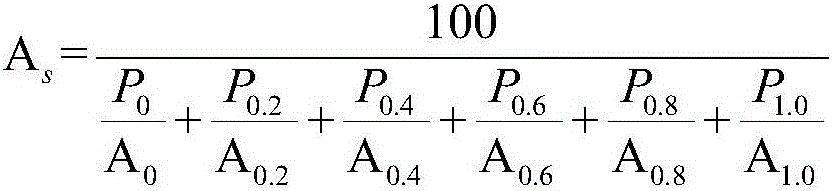

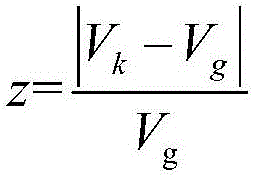

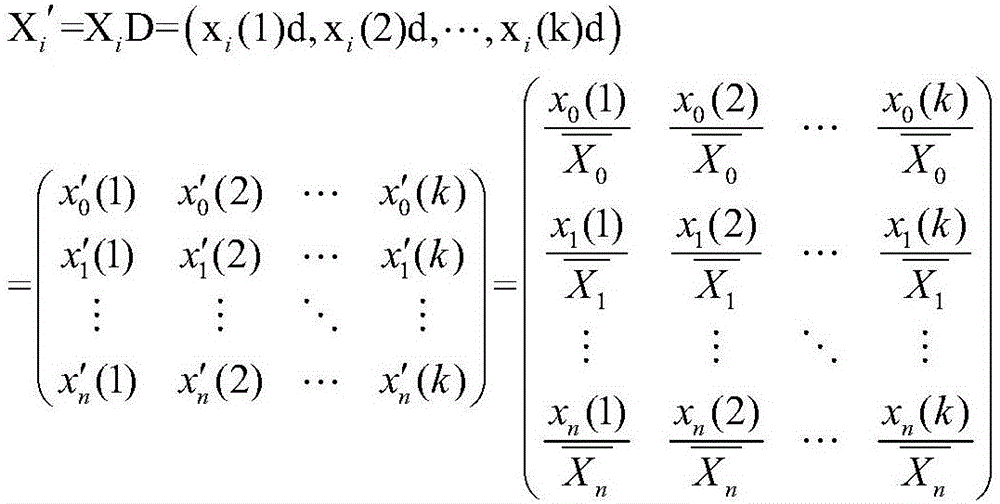

Waste asphalt concrete gradating optimization method based on grey system theory

InactiveCN104496284AImprove road performanceImprove high temperature stabilitySolid waste managementForecastingPorosityEffective factor

The invention discloses a waste asphalt concrete gradating optimization method based on grey system theory, belonging to the material technical field. The method includes performing grading pre-treatment of waste asphalt concrete, building virtual screen size gradation among each grade of waste asphalt concrete direct screening results and the screening results after removal of asphalt, preparing macroporous asphalt concrete under the condition of different virtual screen size gradation blending proportions, performing grey relational analysis and grey correlation degree ordering by adopting porosity deviation changes of macroporous asphalt concrete as the main behavior of the system, and proportional changes of different virtual coefficients in synthesis screening as an effective factor affecting the main behavior, and choosing the virtual screen size gradation with maximum correlation as mixture ratio design basis of actual production of recycled asphalt concrete. The method can accurately control the mixture ratio design of the recycled asphalt concrete, improve recycled asphalt concrete performance, and provide theoretical guidance for application of the waste asphalt concrete in skeleton asphalt mixture.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

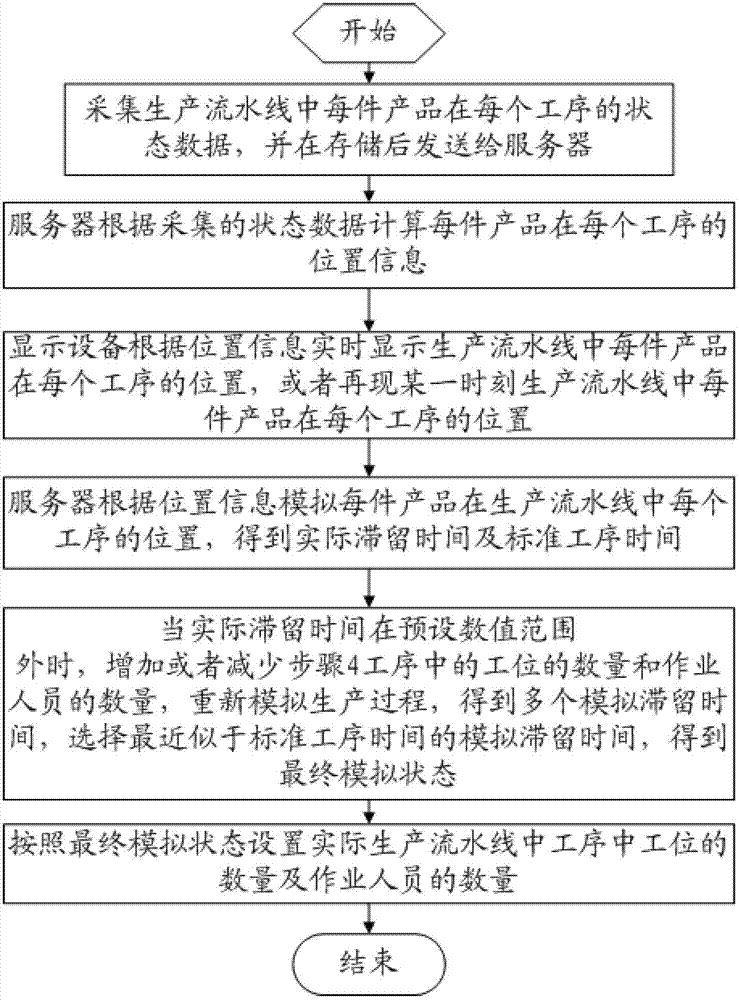

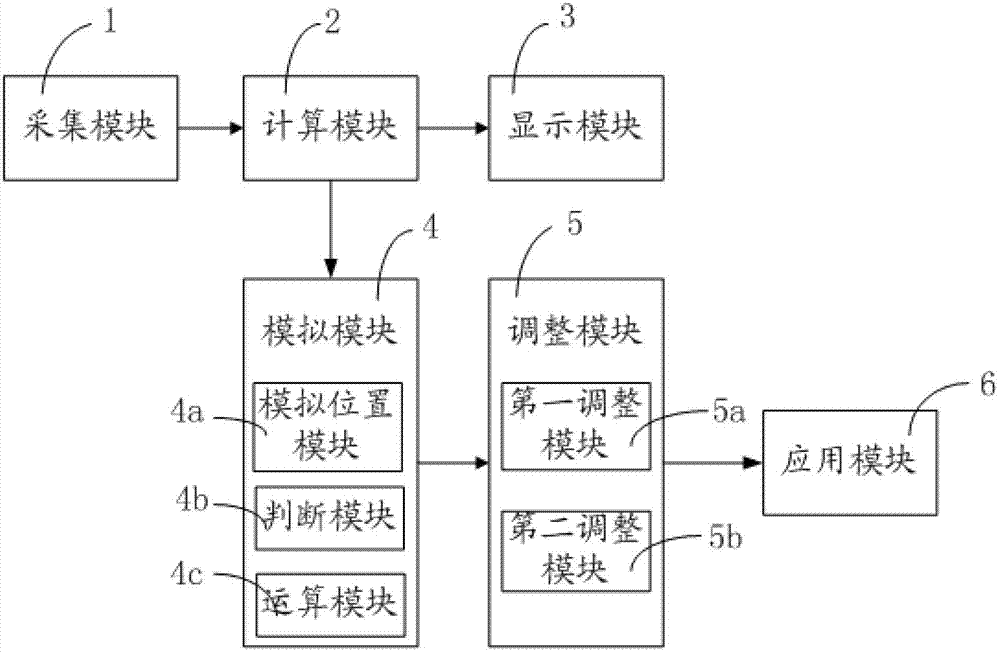

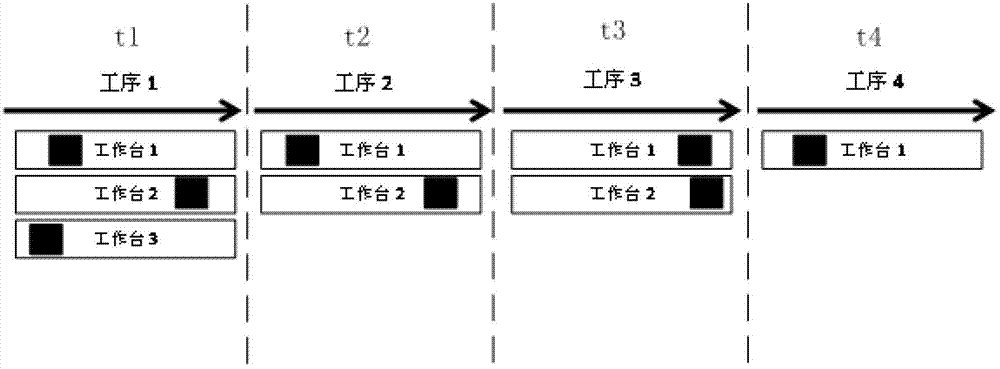

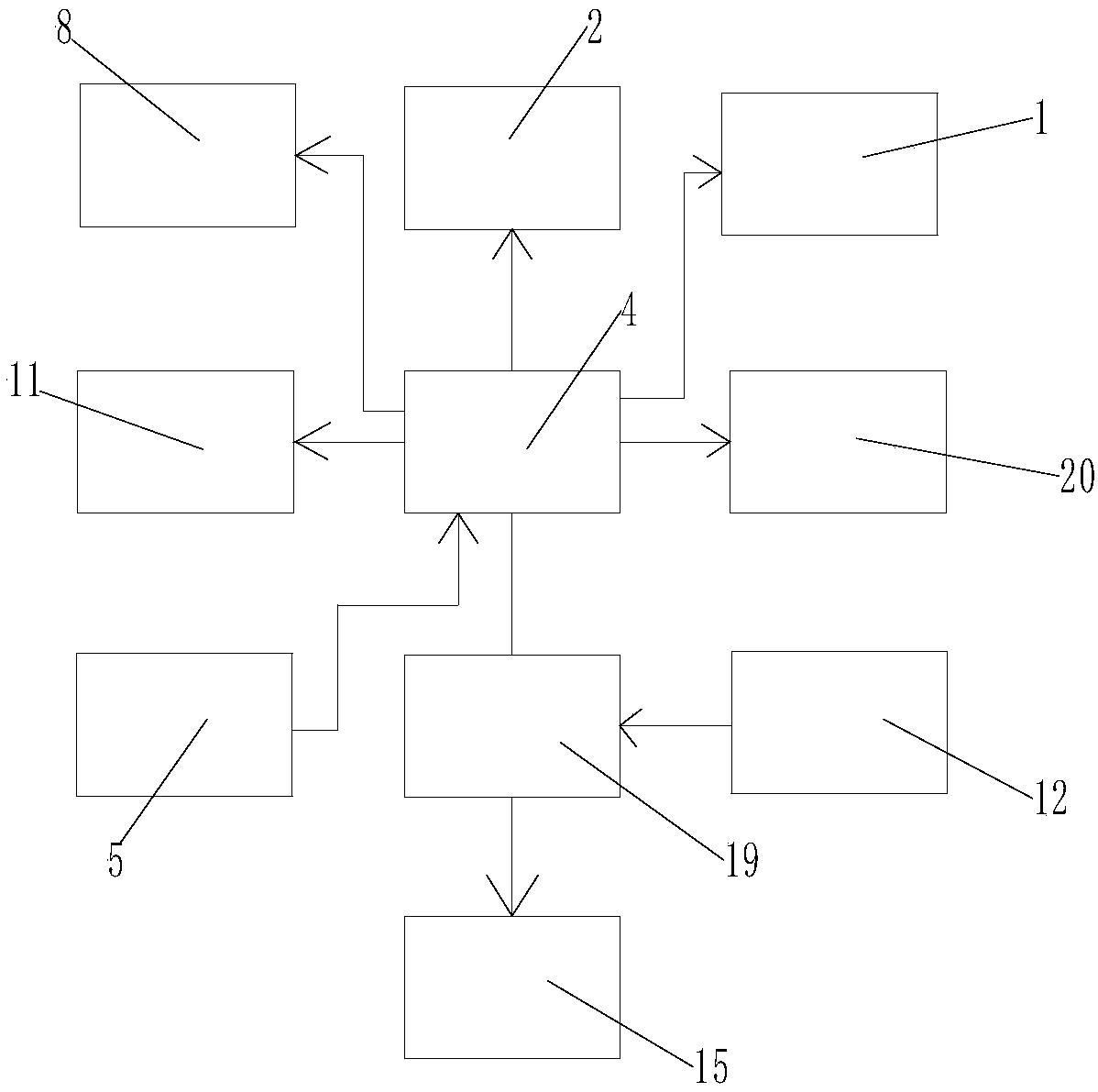

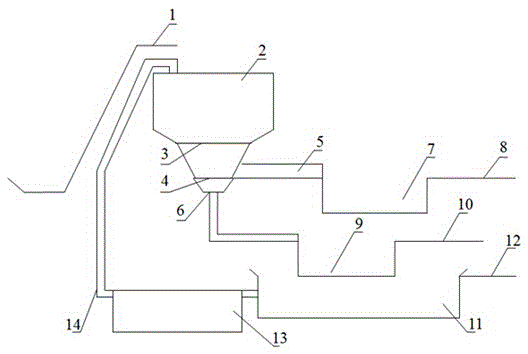

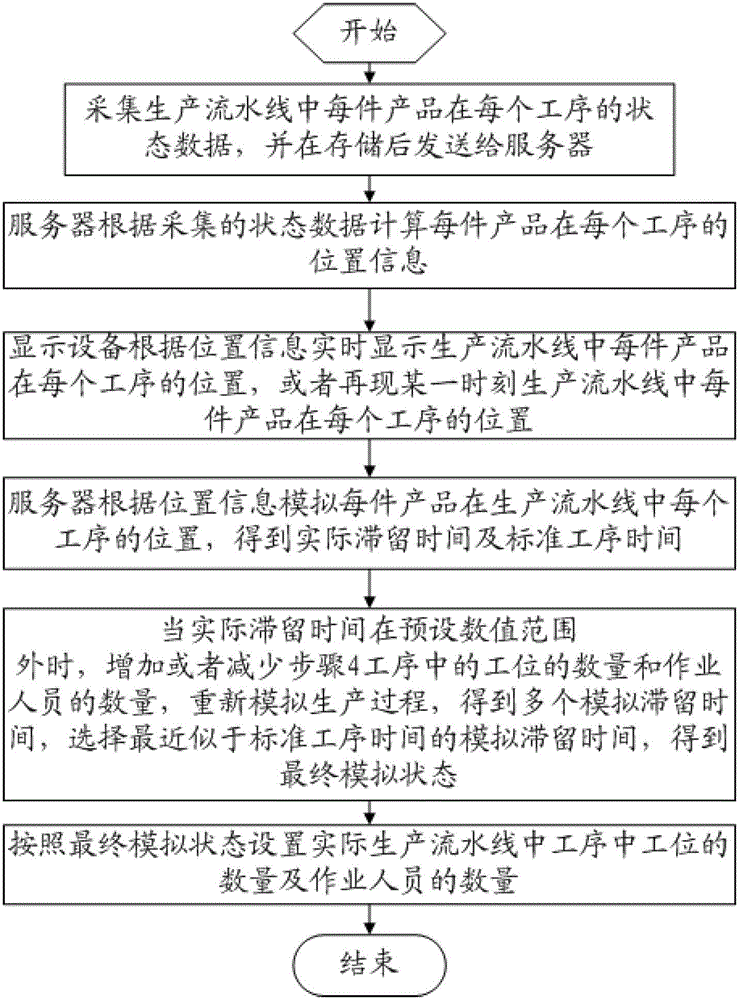

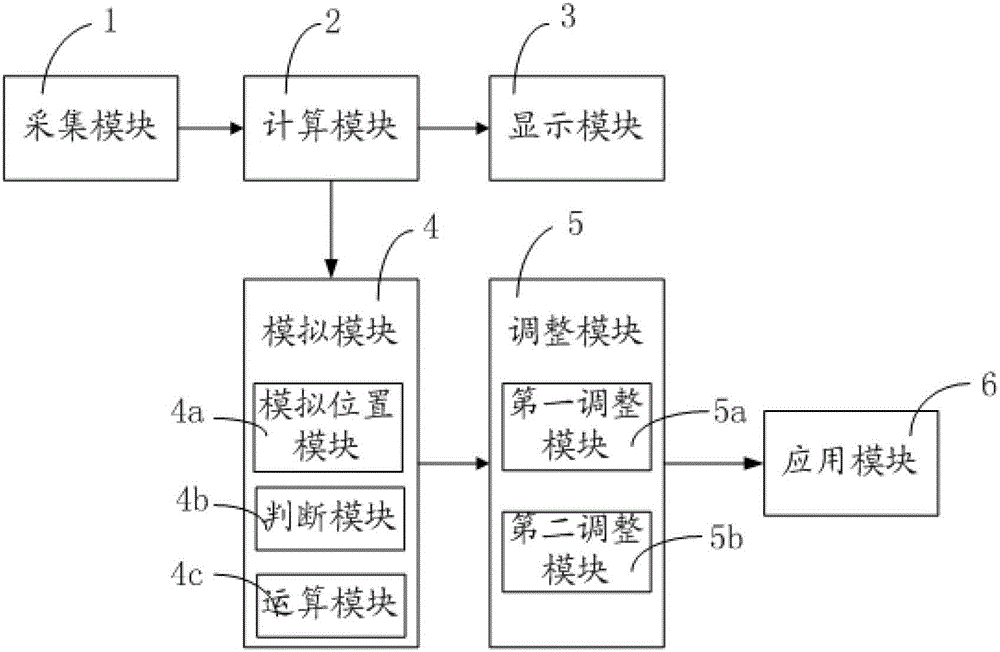

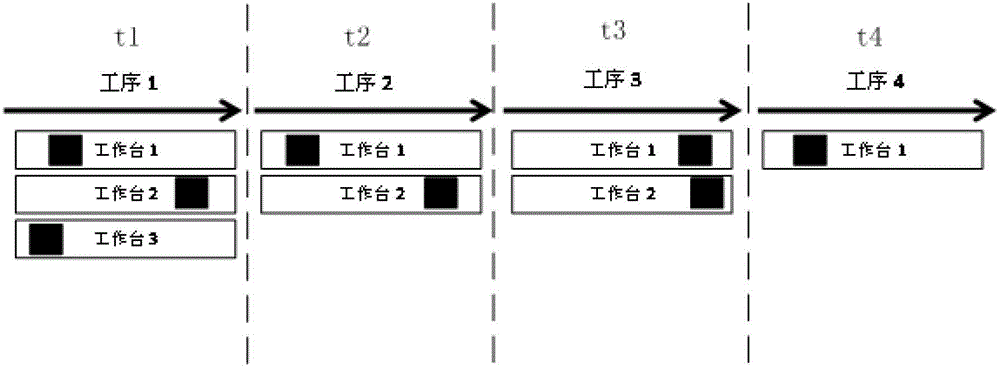

Method and device of assembly line monitoring management

InactiveCN103197623AEasy to findReduce cloggingProgramme total factory controlProduction lineDisplay device

The invention relates to a method and a device of assembly line monitoring management. The method includes the following steps that state data of each product in the assembly line in each process are collected, a server calculates location information of each product in each process according to the collected state data, a display device displays the location of each product in each process in the assembly line according to the location information, the server simulates the location of each product in each process in the assembly line according to the location information, actual residence time and standard process time are obtained, when the actual residence time is out of a preset value range, the number of processes in the simulation process in the step 4 is adjusted to obtain a final simulation status, and the number of stations and the number of operating personnel in the processes in the actual assembly line are set according to the final simulation status. According to the method and the device of the assembly line monitoring management, the problems in the assembly line can be discovered timely and conveniently, resources of all processes can be used to a maximum degree, stoppage and waiting time of the assembly line are reduced, and production efficiency is improved.

Owner:张舒

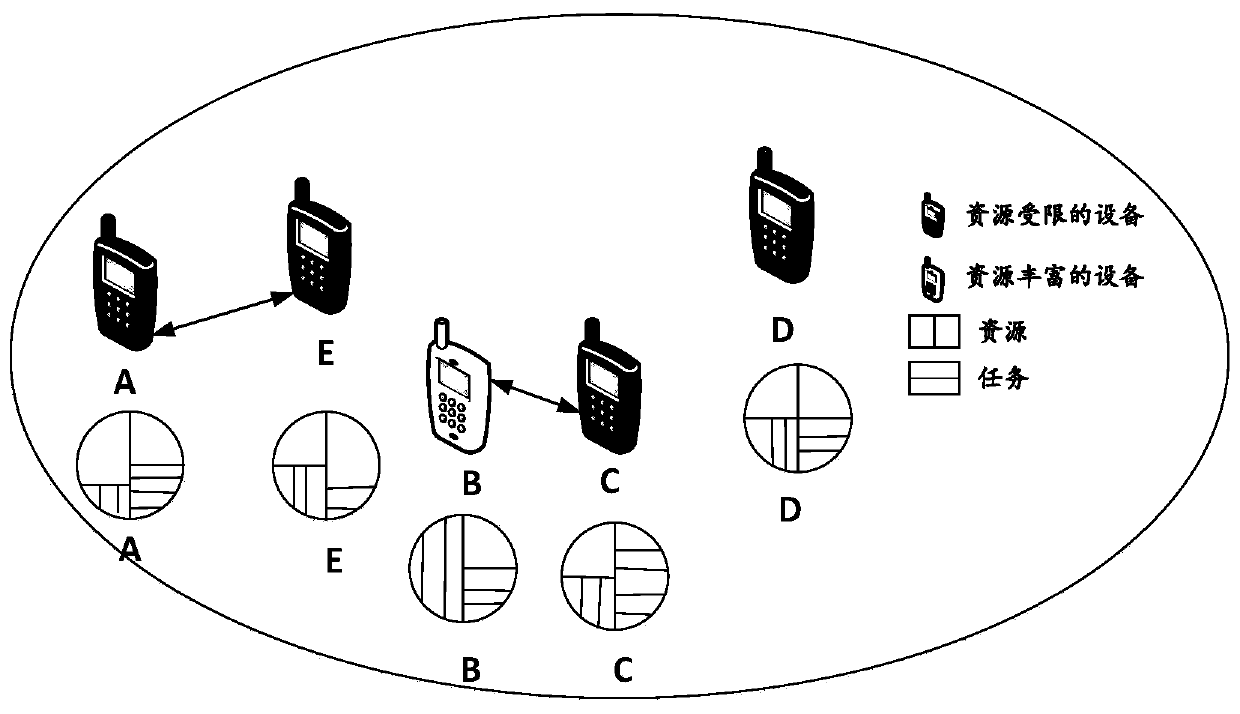

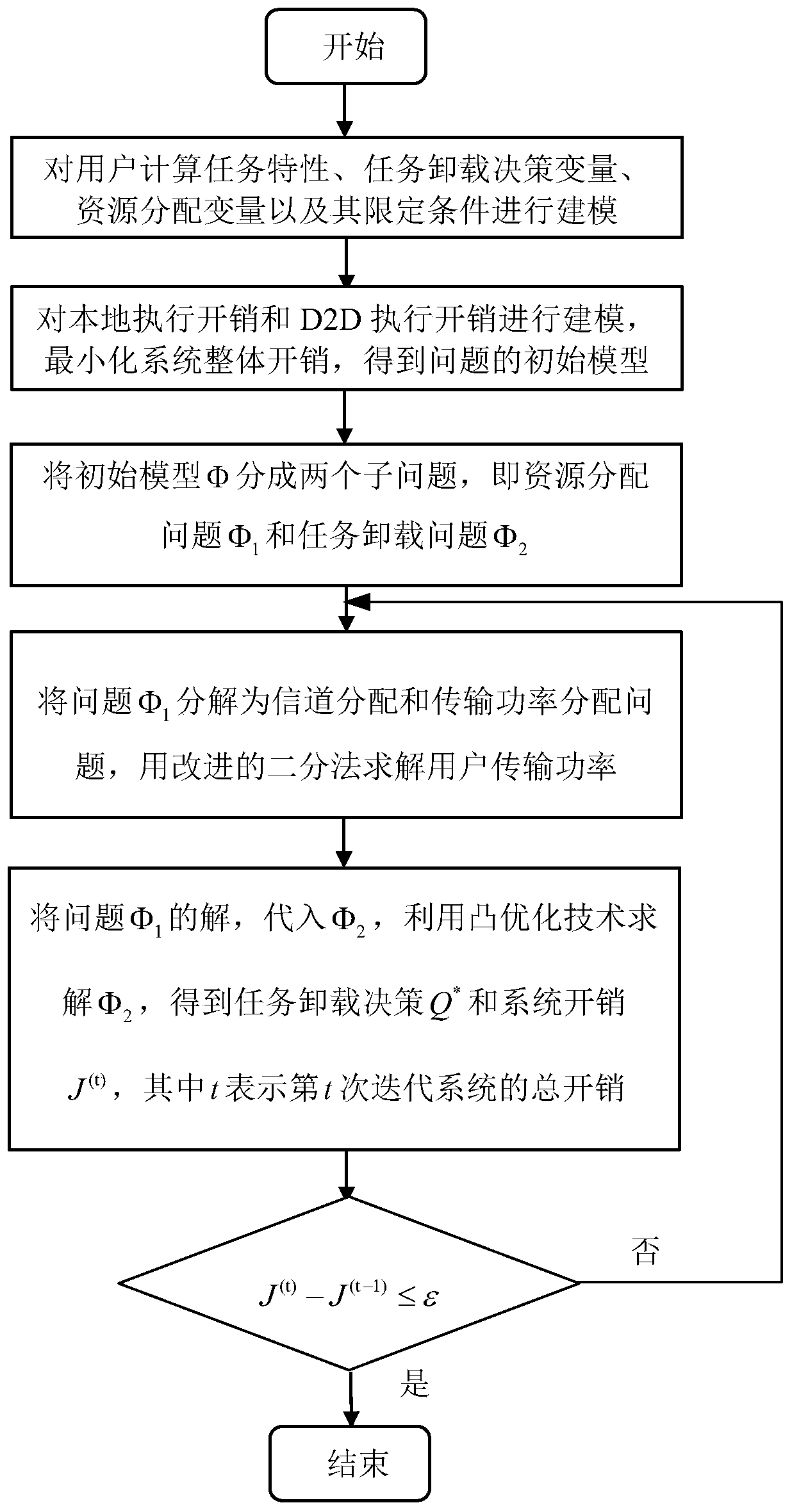

Task unloading and resource allocation method based on D2D communication

InactiveCN110401936AImprove computing powerResource utilizationMachine-to-machine/machine-type communication serviceLimited resourcesCommunication quality

The invention discloses a task unloading and resource allocation method based on D2D communication, and belongs to the technical field of wireless communication. According to the method, it is assumedthat used users can be mutually unloaded, meanwhile, channel interference is considered, and modeling is carried out with the purpose of minimizing the total overhead of a system as the purpose, andthen the problem is decoupled into two sub-problems, the two sub-problems are respectively solved by utilizing pseudo-convex and convex optimization technologies, the two sub-problems are iterativelysolved, and finally an optimal solution of the problem is obtained. According to the method provided by the invention, the mutual unloading between the user equipment is considered, and the reasonablecalculation task is allocated to the user equipment according to the resources (calculation capability, residual electric quantity and the like) owned by the user equipment, so that the equipment with limited resources can participate in calculation, the resources are reasonably utilized, and the calculation performance of all users is improved. Besides, through interference management and powercontrol, channels are reasonably distributed to users, and D2D communication quality can be guaranteed.

Owner:HARBIN ENG UNIV

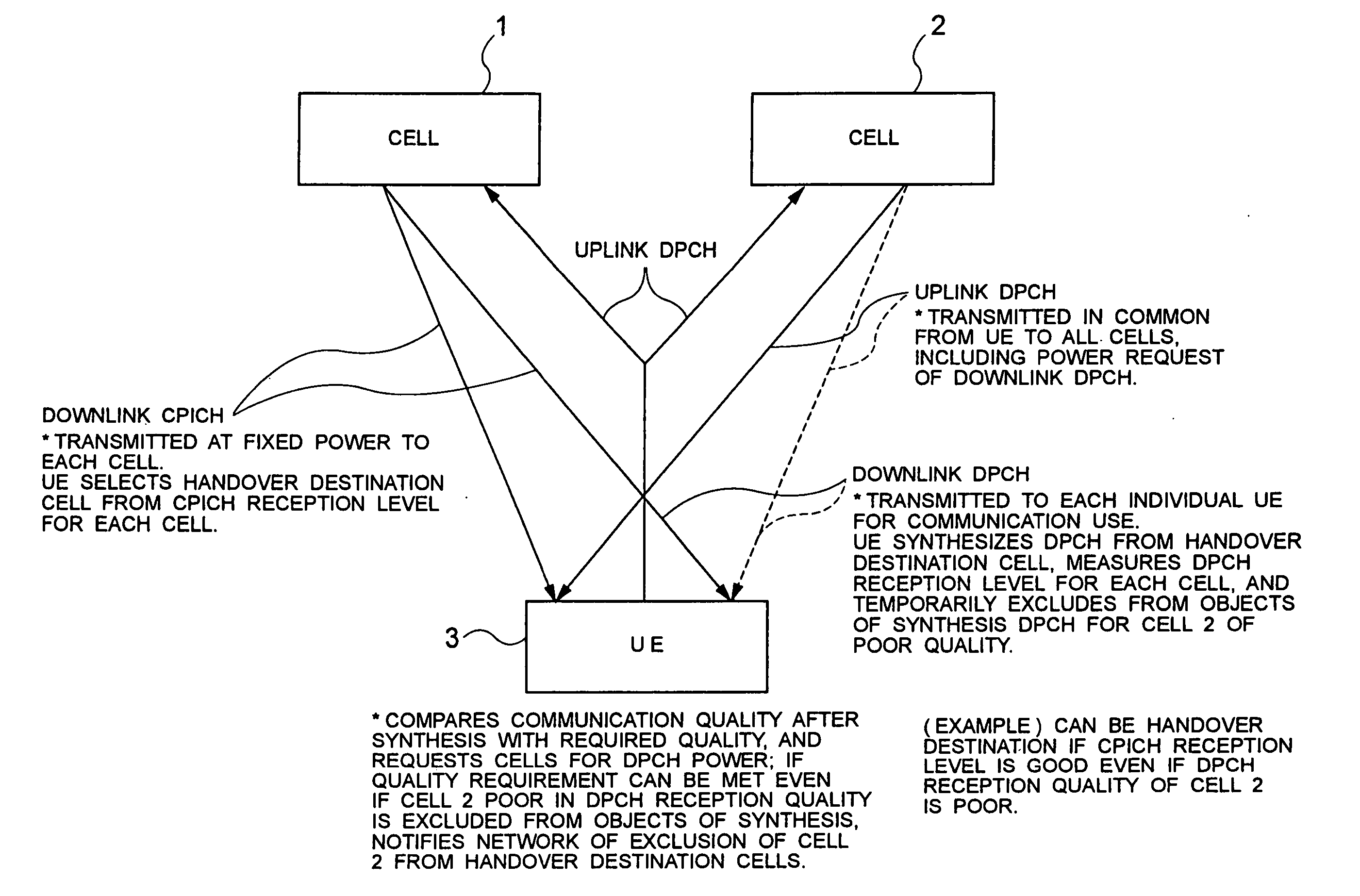

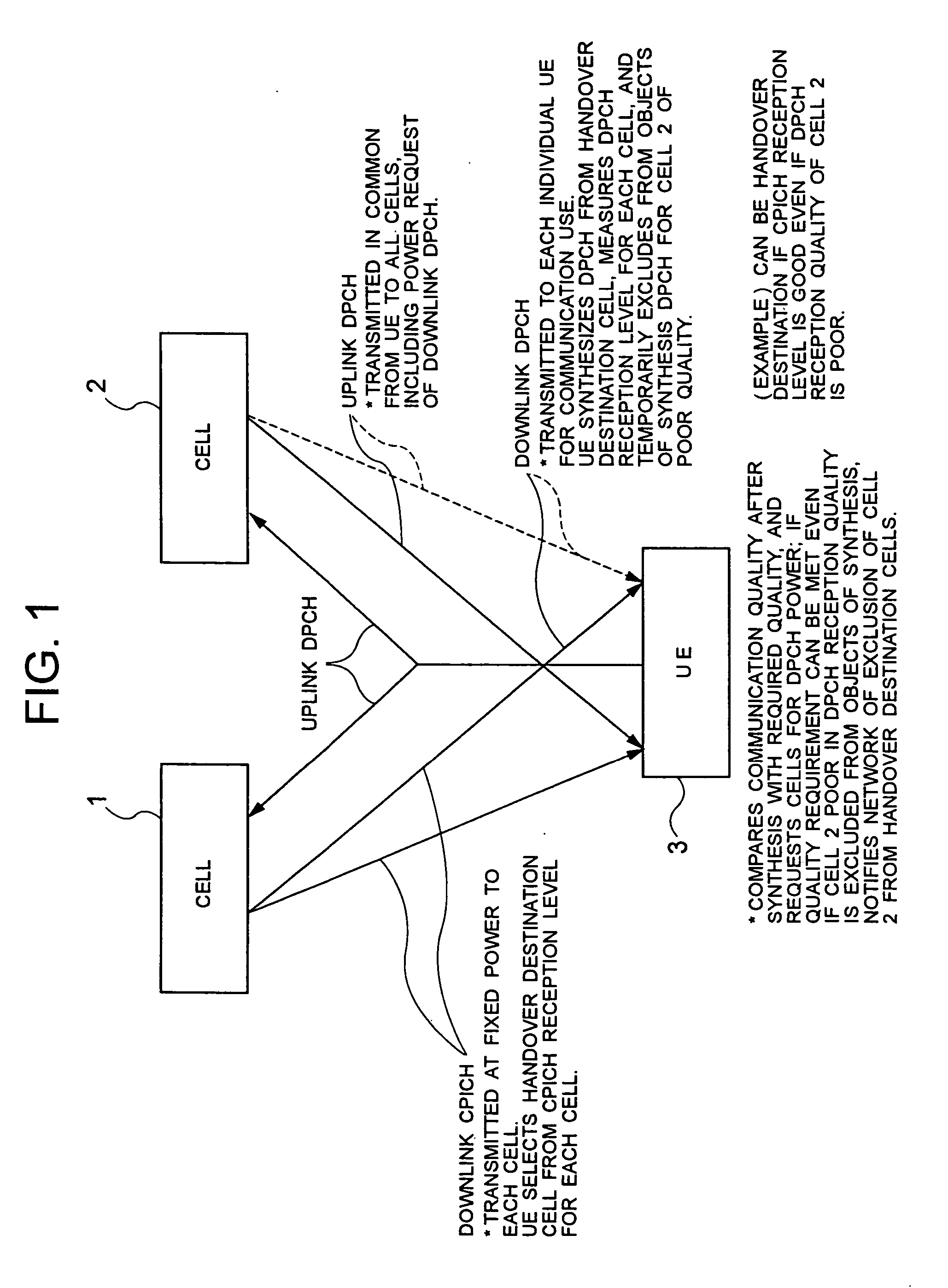

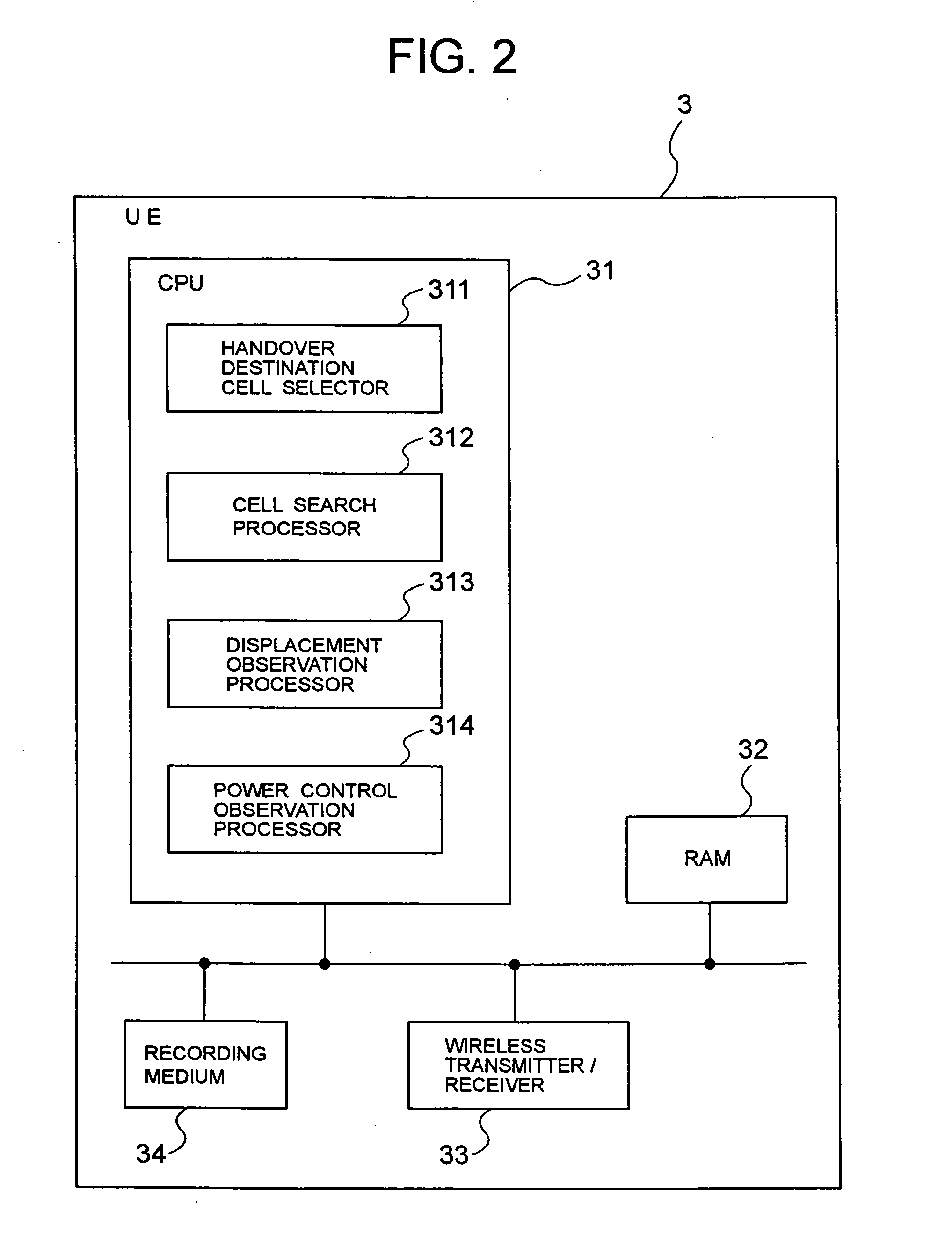

Mobile communication system, UE, handover control method for use thereof and program thereof

InactiveUS20060040668A1Steady communicationResource utilizationPower managementRadio/inductive link selection arrangementsCommunication qualityReal-time computing

The present invention provides a mobile communication system capable of effectively utilizing the limited reception resources available to the UEs and thereby performing steady communication for use in the handover control of UEs. A UE, during communication, determines a handover destination cell according to the result of measurement of the CPICH reception level of each of cells: (1) it measures the reception quality of the downlink DPCH of each of the cells and utilizes the result for the selection of the handover destination cell; (2) switches the handover destination cell and searches for a cell needed for obtaining required communication quality; (3) observes the displacement of the CPICH path loss of each of the cells; and (4) observes whether or not the downlink DPCH transmission power is controlled on the basis of the power request from the UE for each of the handover destination cells.

Owner:LENOVO INNOVATIONS LTD HONG KONG

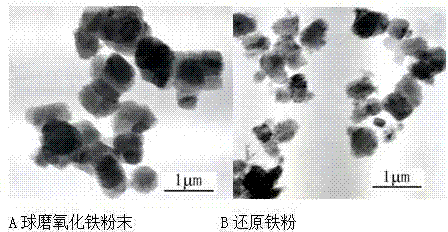

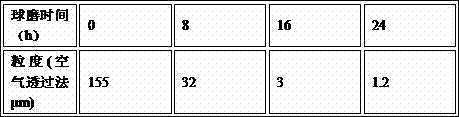

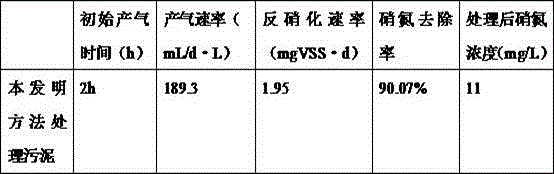

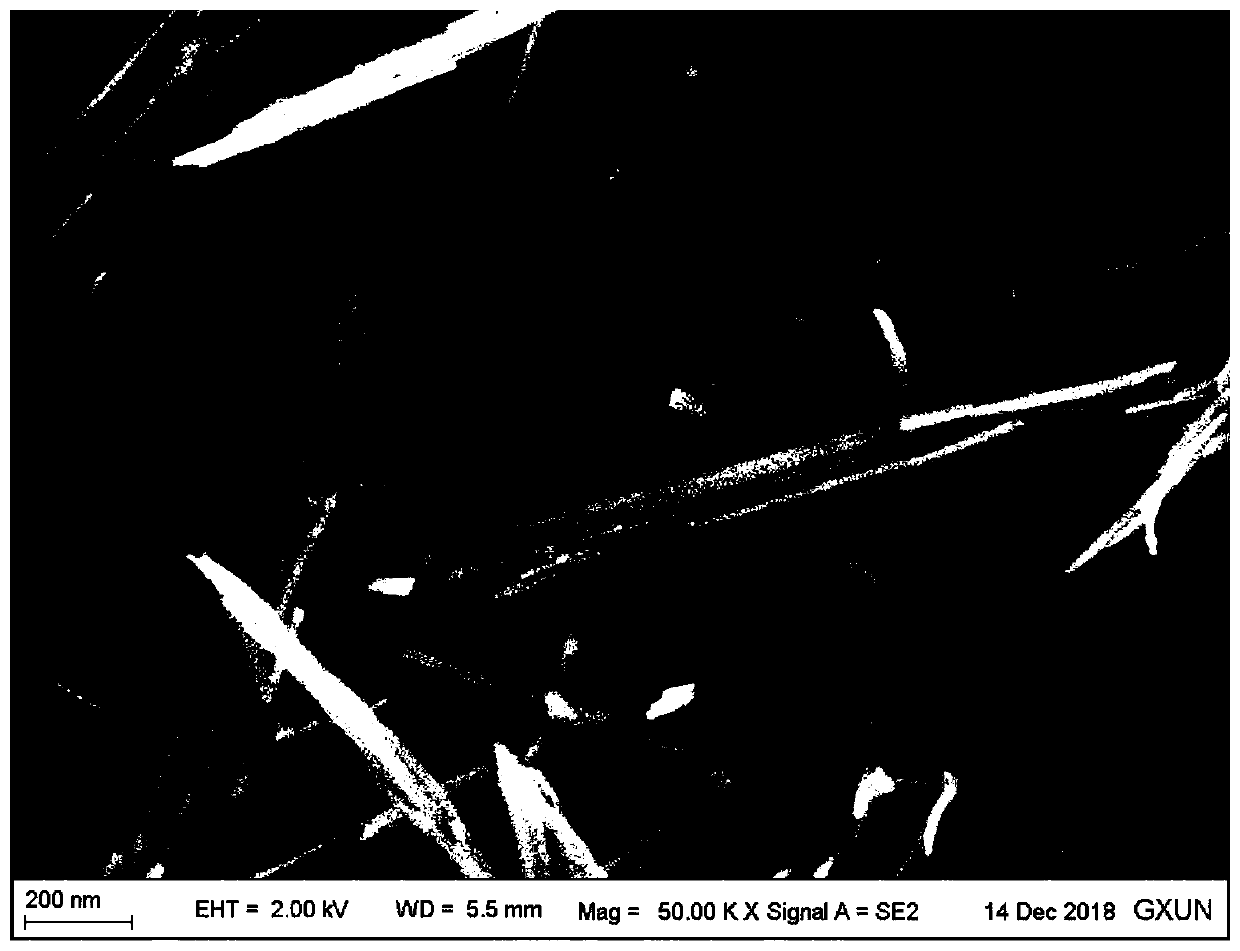

Micron-sized ultrafine iron powder preparation method

Owner:上海寰保渣业处置有限公司 +1

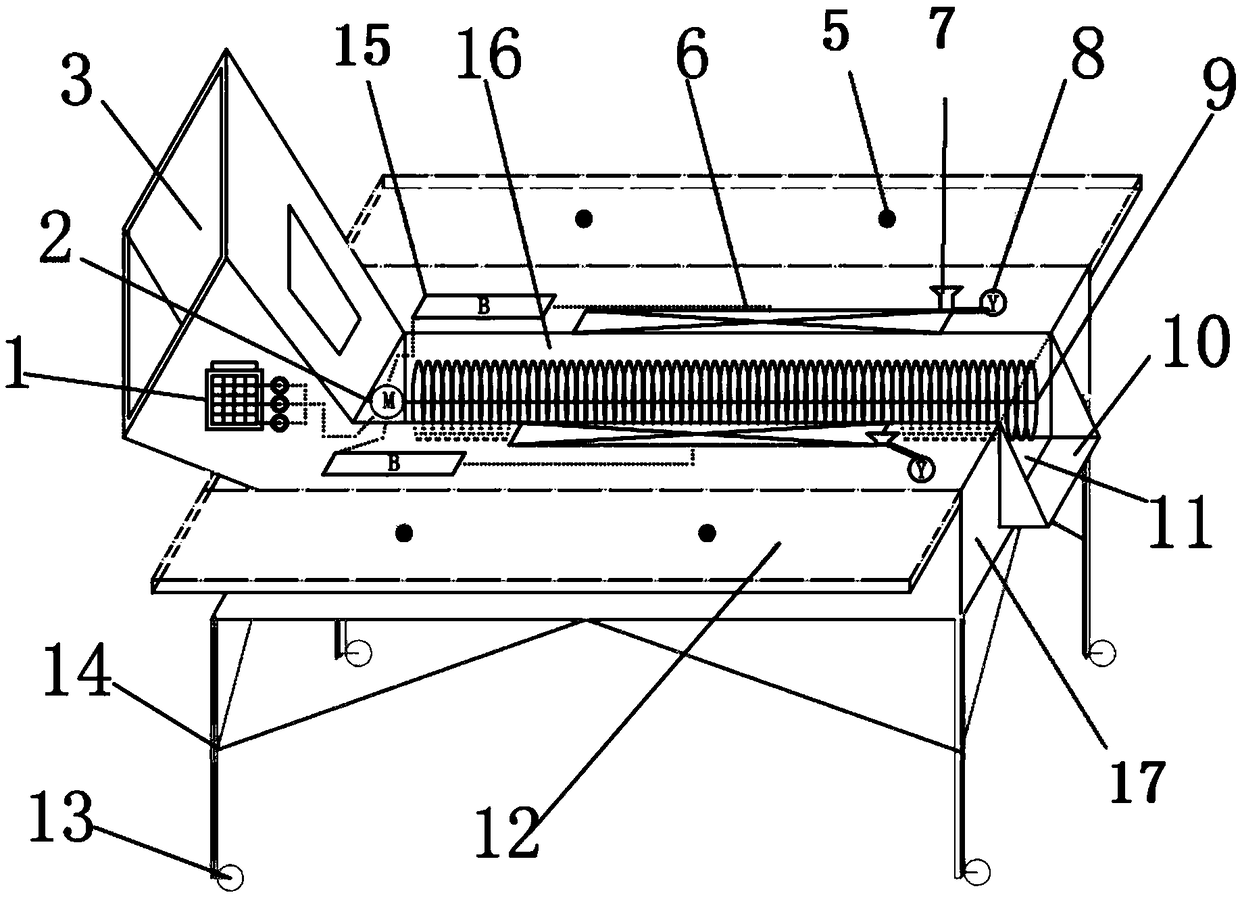

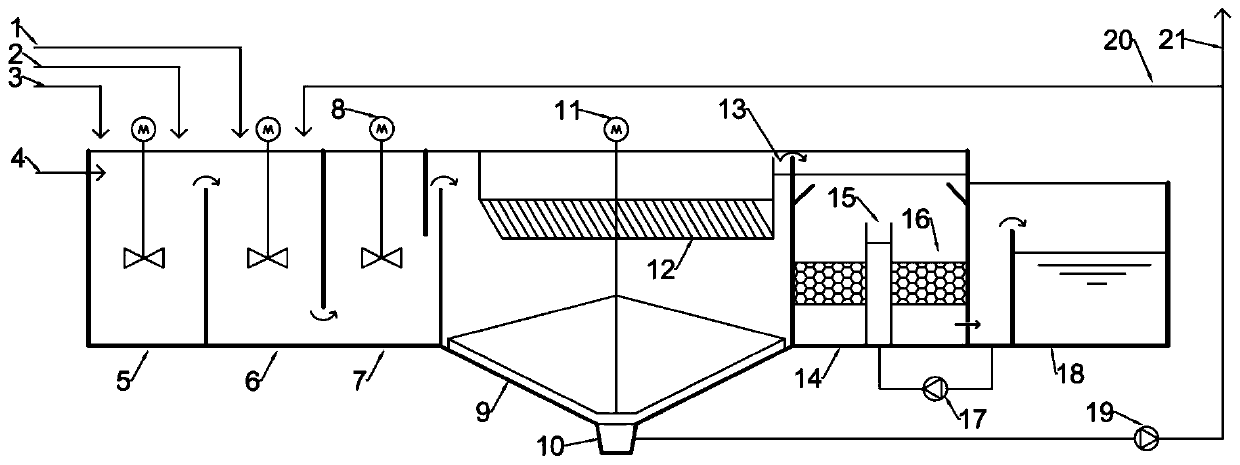

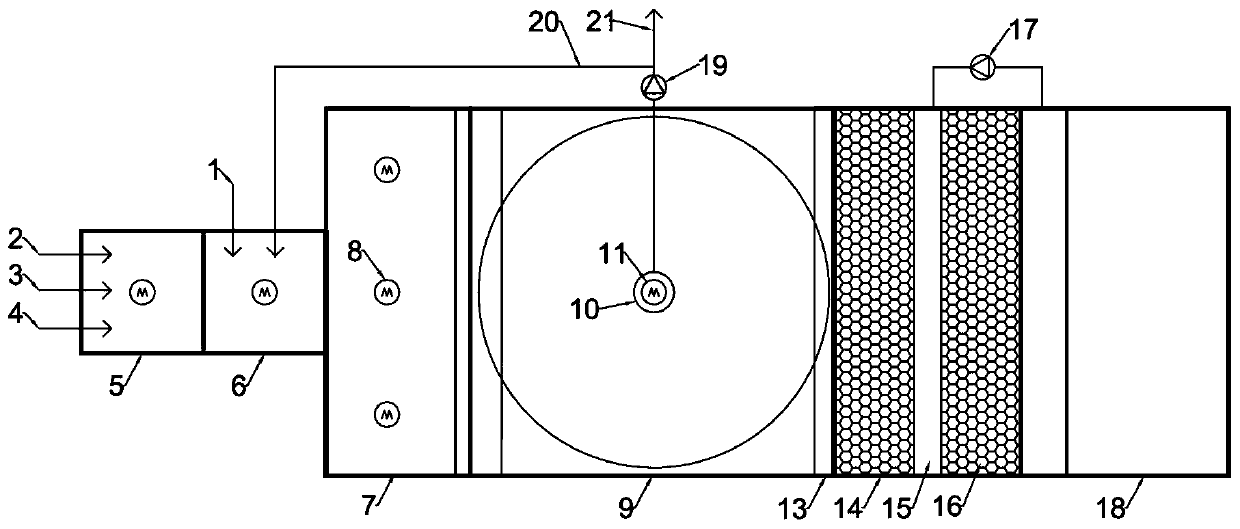

Novel kitchen waste residue-liquid separating device

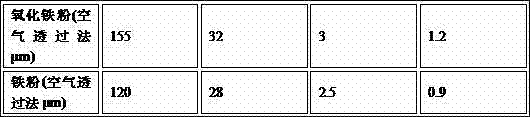

InactiveCN103908817AAchieve separationResource utilizationStationary filtering element filtersLiquid wasteHelical blade

The invention relates to a kitchen waste resource recycling and residue-liquid separating device, and in particular relates to a novel kitchen waste residue-liquid separating device. The novel kitchen waste residue-liquid separating device is characterized by comprising a feeding box, a residue-liquid separator, a waste liquid storage tank and a support, wherein a feeding hole of the feeding box is communicated with a kitchen downcomer, a discharge hole of the feeding box is communicated with a feeding hole of the residue-liquid separator, the residue-liquid separator comprises a barrel body, a stranding cage, a first bearing block, a second bearing block and a motor, the barrel body is obliquely arranged on the waste liquid storage tank, a helical blade part of the stranding cage is positioned in the barrel body, a waste liquid outlet is formed in the bottom surface of the lower end part of the barrel body and is communicated with the waste liquid storage tank, and a waste residue outlet is formed in the bottom surface of the upper end part of the barrel body. The novel kitchen waste residue-liquid separating device has the characteristics of having capacitiy of continuously separating residue and liquid and discharging residue automatically without limitation of kitchen drainage, is suitable for recycling in kitchen waste production places.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

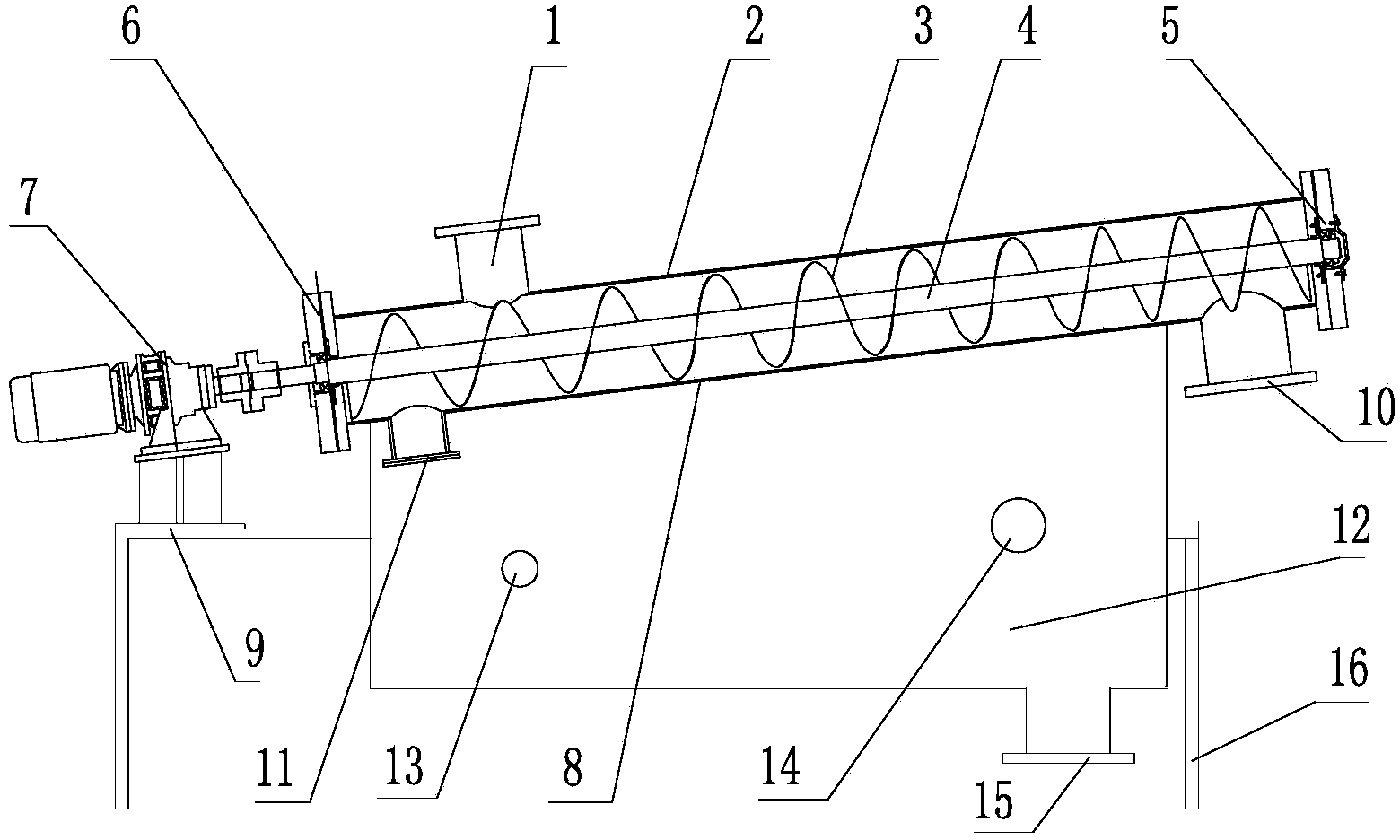

Microbial preparation for sludge anaerobic fermentation

InactiveCN106754543ALower initial costAdaptableBacteriaMicroorganism based processesBacillus amyloliquefaciensSludge

The present invention belongs to the field of microbial technology and discloses a microbial preparation for sludge anaerobic fermentation. The microbial preparation comprises a mixed bacteria liquid and a carrier, wherein the mixed bacteria liquid is prepared from Bacillus pumilus, enterobacter cloacae, denitrifying bacteria, paracoccus denitrificans, bacillus amyloliquefaciens, and lactococcus lactis. The microbial preparation can greatly increase the amount of methane generated by sludge, increase the utilization rate of the sludge, and recycle the sludge.

Owner:王筠涵

Method for preparing sludge with strongly-acidic fluorine-containing waste water to prepare calcium fluoride concentrate

PendingCN109399687AHigh degree of refinementMeet resource utilizationCalcium/strontium/barium fluoridesFlotationEtherSODIUM DODECYL BENZENE SULFONATE

The invention discloses a method for preparing sludge with strongly-acidic fluorine-containing waste water to prepare calcium fluoride concentrate. The method includes the steps that 1, calcium fluoride sludge is pre-treated and pulped after being treated, the calcium fluoride sludge, a trapping agent, a foaming agent and an adjusting agent are mixed and stirred, and the mixture is subjected to flotation, wherein the trapping agent is one or more of oleic acid, sodium alkyl sulfate, sodium naphthenate and modified fatty acid salt compound sodium dodecyl benzene sulfonate, the foaming agent isone of terpenic oil, methyl isobutyl carbinol and butyl ether oil, and the agenting agent is prepared from an activator, an inhibitor, a dispersant sodium carbonate and a flocculant; 2, the calcium fluoride sludge obtained after flotation is mixed with an acid solution; 3, the calcium fluoride sludge obtained after being treated in the second step is mixed with a fluorine-containing solution; 4, acalcium fluoride sludge mixture obtained after being treated in the third step is neutralized through an alkaline solution, the calcium fluoride sludge mixture is after-treated, and the calcium fluoride concentrate is obtained. The method has the advantages of being high in refining degree and achieving resource utilization of multiple industries.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

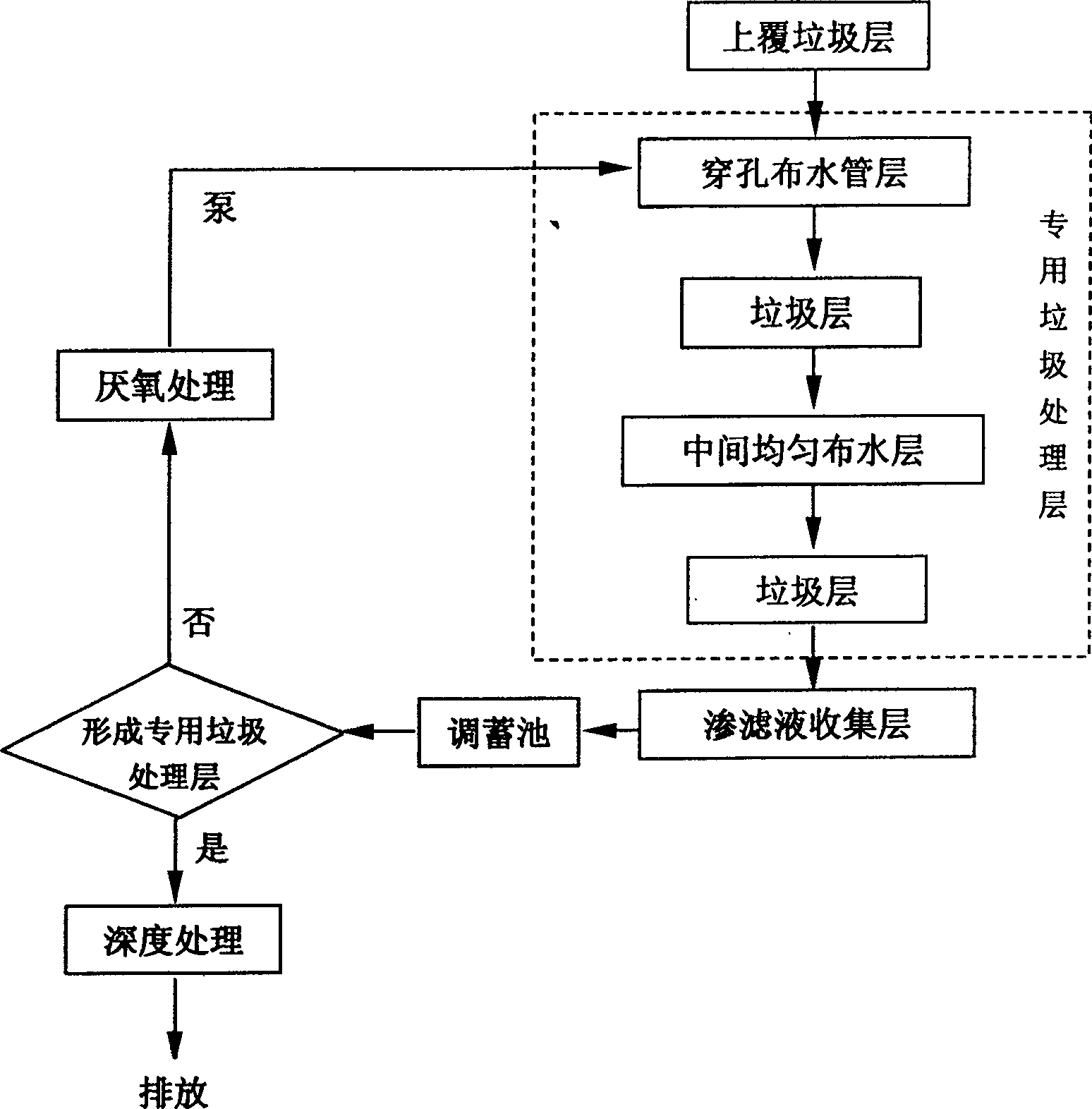

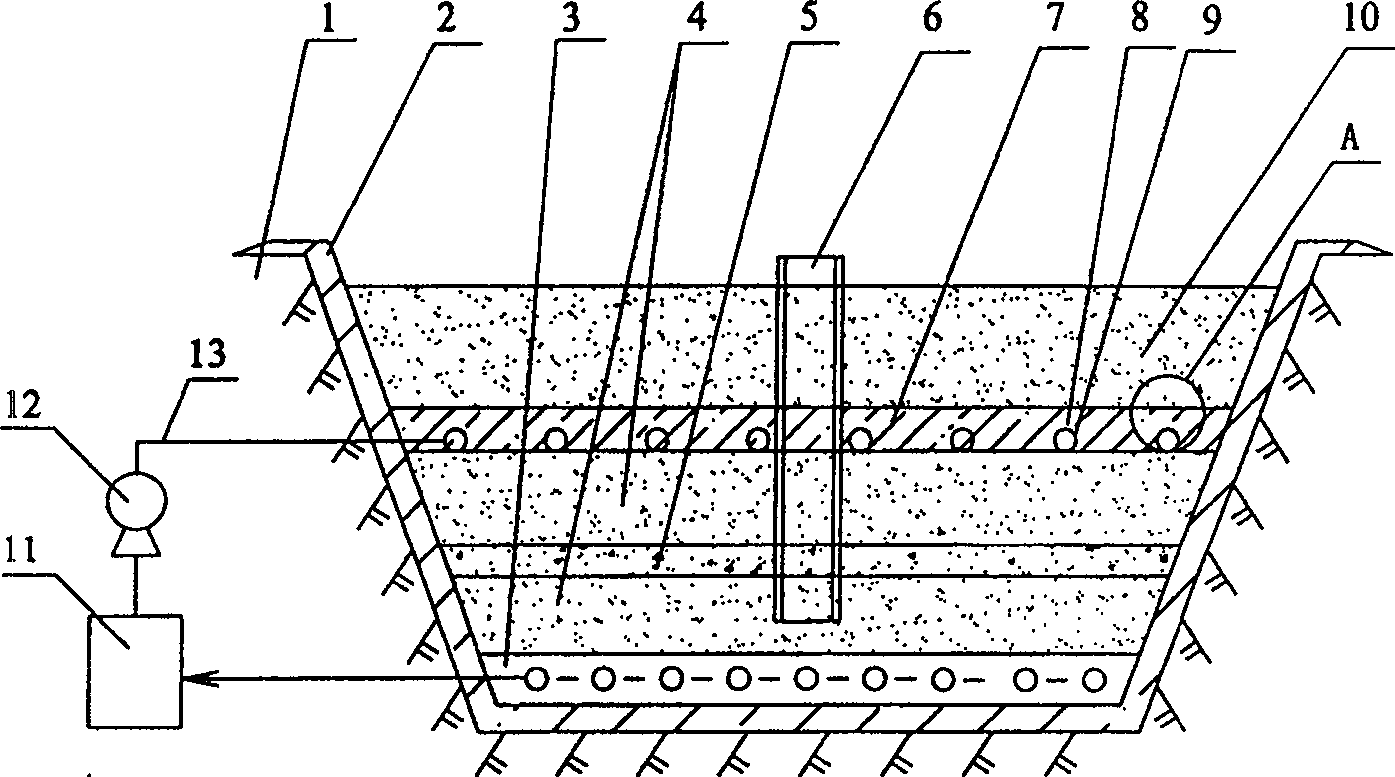

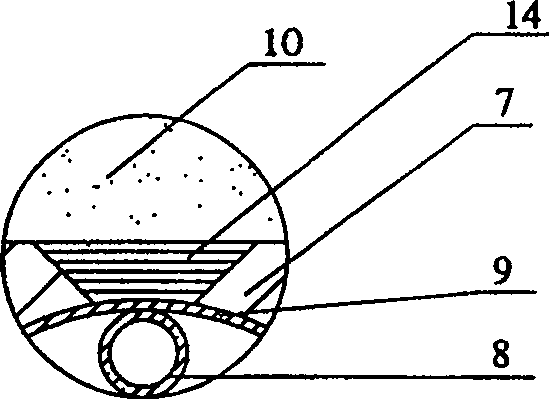

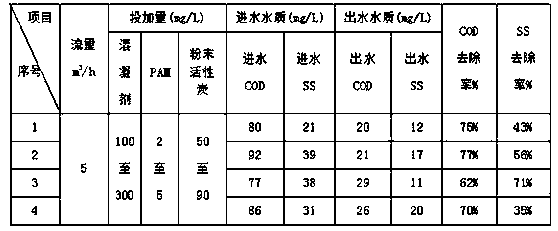

On-spot treatment method for leachate of landfill field

ActiveCN100531942CImprove water qualityLow costSolid waste disposalMunicipal solid waste landfillTherapeutic effect

Owner:TONGJI UNIV

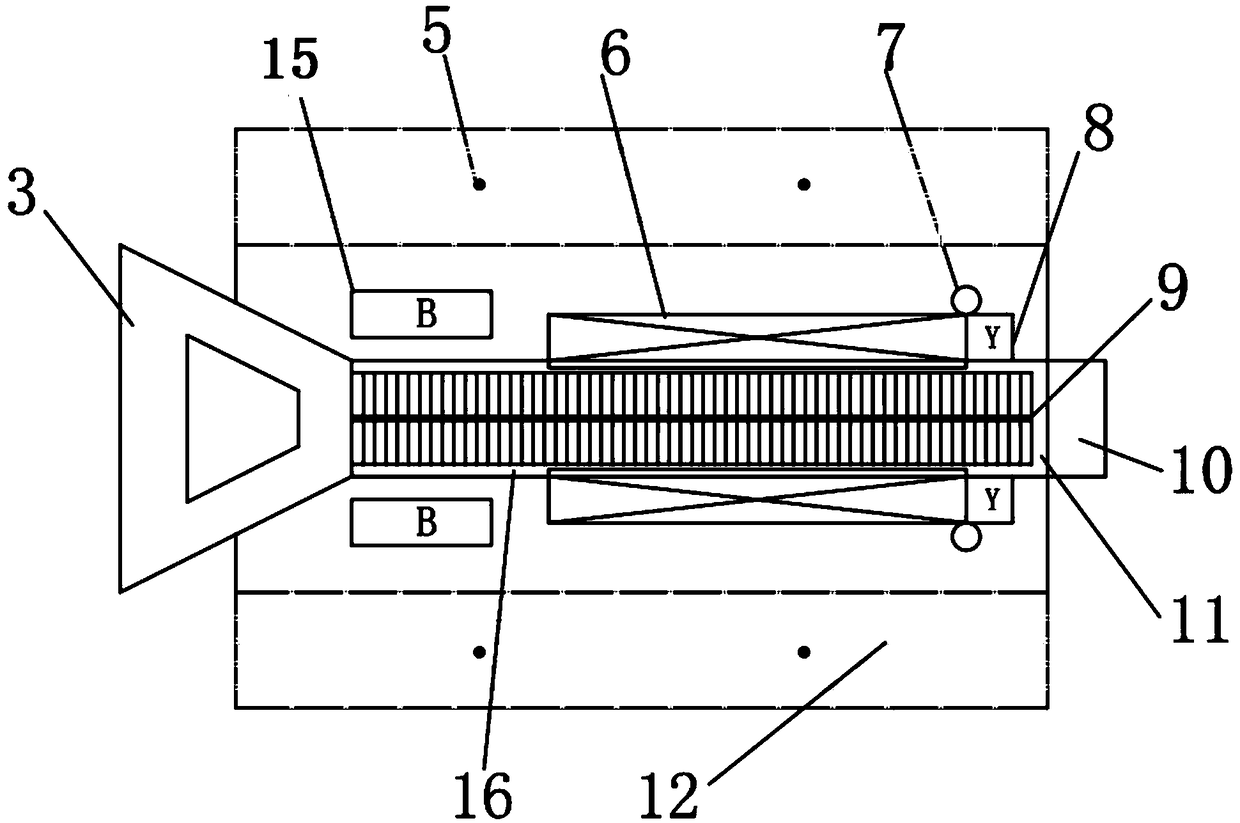

Self-propelled solar sludge drying machine

InactiveCN109052904AReduce processing costsWith reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCarbon dioxide productionSludge

The invention relates to a self-propelled solar sludge drying machine, which comprises a workbench, and the upper surface of the workbench is provided with a sludge feeding trough; a spiral sludge pushing unit is arranged in the sludge feeding trough; a feeding bin is arranged above the feeding end of the spiral sludge pushing unit; and hot air flow generating units are arranged on both oppositvesides of the spiral sludge pushing unit. The self-propelled solar sludge drying machine has the beneficial effects of low cost, no secondary pollution, clean energy use, no carbon dioxide production and no heat production, and achieves the goals of sludge reduction and decontamination, energy conservation, emission reduction and environment-friendliness.

Owner:HUBEI UNIV

Chicken manure moulded solid fuel

InactiveCN105779062ASolve the pollution of the environmentResource utilizationBiofuelsSolid fuelsSodium carbonateRosin

The invention discloses a chicken manure moulded solid fuel, which comprises the following components in parts by weight: 55 to 85 parts of dry chicken manure, 2 to 7 parts of anthracite, 10 to 30 parts of coke, 1 to 3 parts of quicklime, 1 to 1.5 parts of sodium carbonate, 0.5 to 1 part of potassium chloride, 2 to 3 parts of alcohol (35%), and 0.2 to 0.5 part of rosin. The agricultural waste (chicken manure) is converted into valuable resources. The provided solid fuel is clean and environment-friendly and is the best substitute of fossil energy.

Owner:刘良贵

Deep treatment method of pulping paper making wastewater

InactiveCN109879479AShort stayReduce civil costMultistage water/sewage treatmentActive carbonEngineering

The invention discloses a deep treatment method of pulping paper making wastewater. The method comprises the following steps that (1) a system is built; (2) a plurality of wastewater samples are taken; a coagulant, PAM and powdery active carbon are added; a solution is prepared; (3) the wastewater enters a coagulating pool; mixing and stirring are performed; (4) the wastewater enters a reaction pool for forming alumen ustum; the alumen ustum flows into an inclined plate sedimentation pool; a flocculating body is intercepted on an inclined plate; then, precipitates enter a mud collecting pool;a mud backflow pump is used for lifting; most wastewater is reused to the flocculation pool; little wastewater is outwards discharged; the outward discharging quantity can be regulated according to the COD value of outlet water; (5) after being clarified, the wastewater enters a filtering pool for filtering; collection is performed in a clear water pool. By flocculation, adsorption, precipitationand filtering methods, the pulping paper making wastewater is deeply treated; the outlet water quality is enabled to meet higher discharging requirements; the investment and operation cost is reduced;favorable conditions are created for reusing the wastewater in further.

Owner:YUEYANG FOREST & PAPER CO LTD

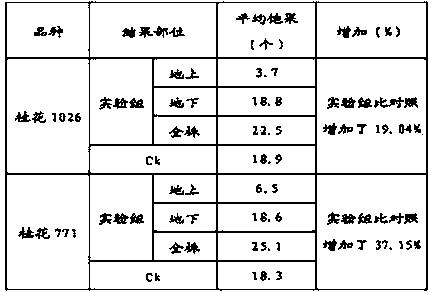

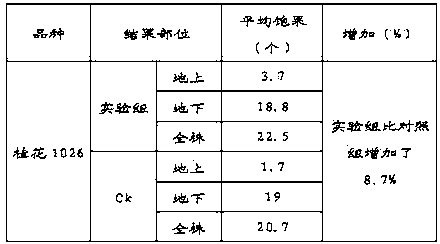

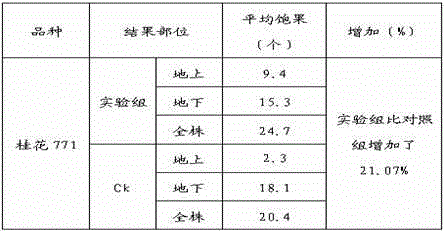

Culture medium for culturing peanut gynophores

ActiveCN103739389AResource utilizationEfficient use ofFertilizer mixturesInterspecific hybridizationGermplasm

The invention discloses a culture medium for culturing peanut gynophores, which is prepared from a seedling raising substrate used as a main raw material, and white lime and a gelatinizer used as auxiliary materials. The culture medium is prepared by evenly mixing the white lime, gelatinizer and seedling raising substrate in a mass ratio of 1:(5-380):(25-1520). The culture medium mainly solves the problem that the overground gynophores of peanuts can not penetrate into soil to develop into full pods, enhances the propagation coefficients of peanut hybrid F1 and rare seed resources, and can solve the problem that the interspecific cross subsequent generation can not form pods since the plant grows vigorously and the gynophores are too far away from the ground.

Owner:广西壮族自治区农业科学院经济作物研究所

Preparation and use method of composite deoxidized modified pellets

The invention discloses a preparation and use method of a composite deoxidized modified pellet. The ppreparation and use method comprises the following steps of A pellet, specifically, the the balling components of the A pellet comprises the following components of, in parts by mass, 30-40 parts of dolomite powder, 20-30 parts of steel slag powder, 20-30 parts of process coke breeze, 1.5-2 parts of an X-type organic binder, 15-20 parts of a Y-type inorganic binder and 3 parts of water, and is produced by adopting a cold pressing pellet process; and B pellet, specifically, the balling components of the B pellet comprises the following components of, in parts by mass, 30-40 parts of dolomite powder, 20-30 parts of limestone powder, 20-30 parts of process coke breeze, 1.5-2 parts of an X-type organic binder, 15-20 parts of a Y-type inorganic binder and 3 parts of water, and is procuced by adopting the cold pressing pellet process; and the A pellet and the B pellet are correspondingly in two process links of a converter and a refining furnace.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

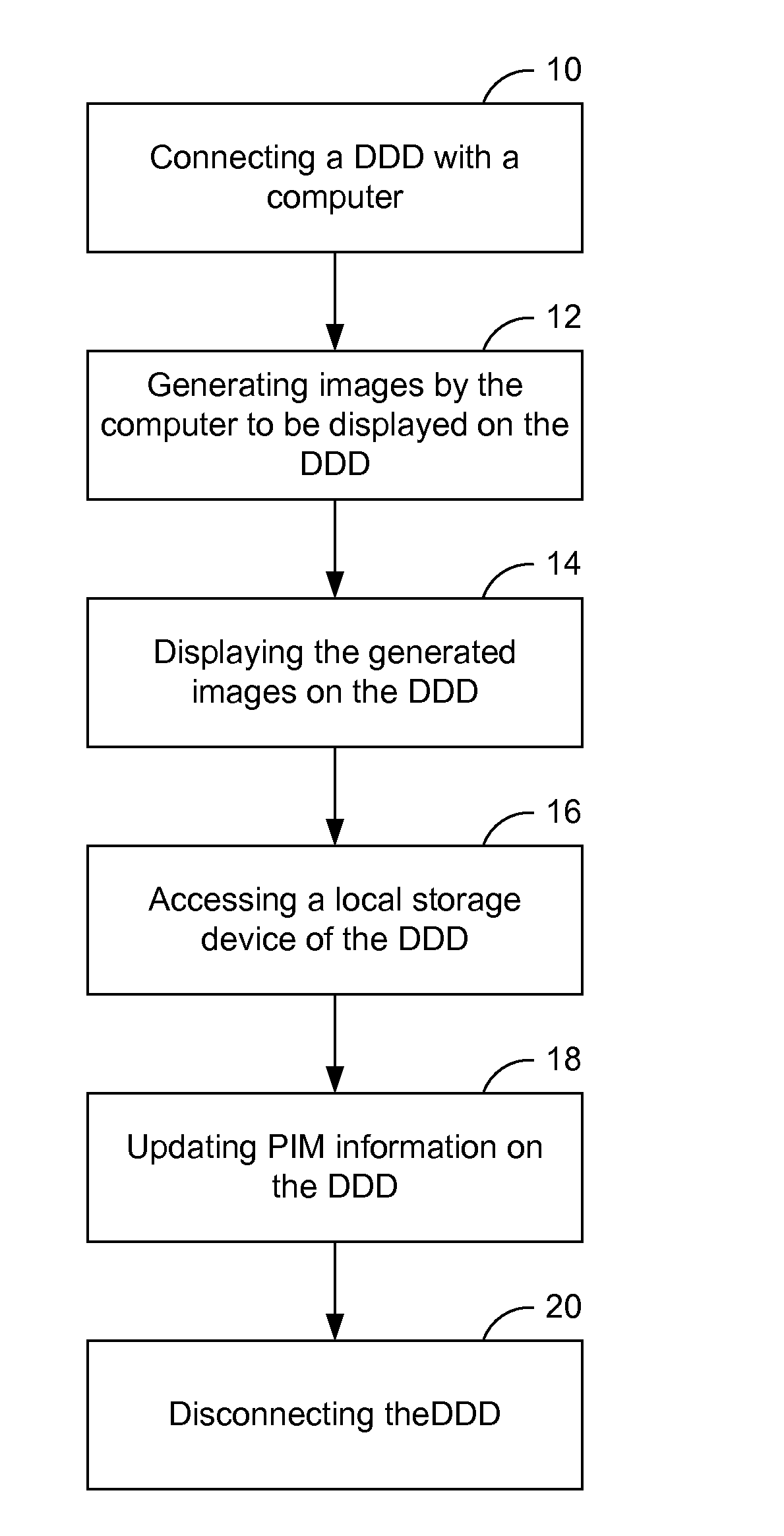

Methods for Utilizing the Resources of a Digital Display Device by a Computer

InactiveUS20100205146A1Resource utilizationMemory loss protectionStatic indicating devicesDisplay deviceWorld Wide Web

A method for utilizing the resources of a digital display device (“DDD”) for use by a computer comprises the steps of: connecting the DDD to the computer; displaying one or more images on the DDD, wherein the images are transmitted from the computer to the DDD; updating and storing PIM information on the DDD, wherein the PIM information is retrieved from the computer; and generating by the DDD one or more alerts based on the updated PIM information to be displayed on the DDD.

Owner:AMLOGIC

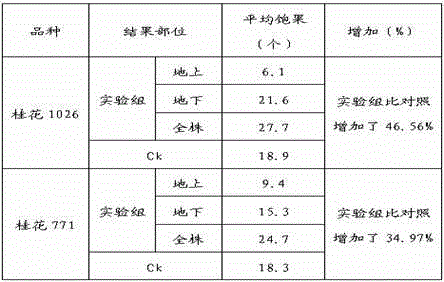

A kind of culture medium for peanut needle cultivation

The invention discloses a culture medium used for peanut needle culture, wherein a seedling matrix served as a main raw material is matched up with calcium superphosphate and gels, and the culture medium is prepared by uniformly mixing the calcium superphosphate, the gels and the seedling matrix according to the mass ratio of 1: (4-110): (16-440). According to the culture medium, the problems that pods can not be formed by high peanut needles and the upper peanut needles can not be developed to be full pods can be solved, so that the propagation coefficients of peanut hybrid generation F1 and valuable and rare genetic resources can be improved, and the problem that the pods can not be formed by interspecies cross filial generations due to the fact plants grow flourishingly and the peanut needles are too far away from the ground can be solved.

Owner:广西壮族自治区农业科学院经济作物研究所

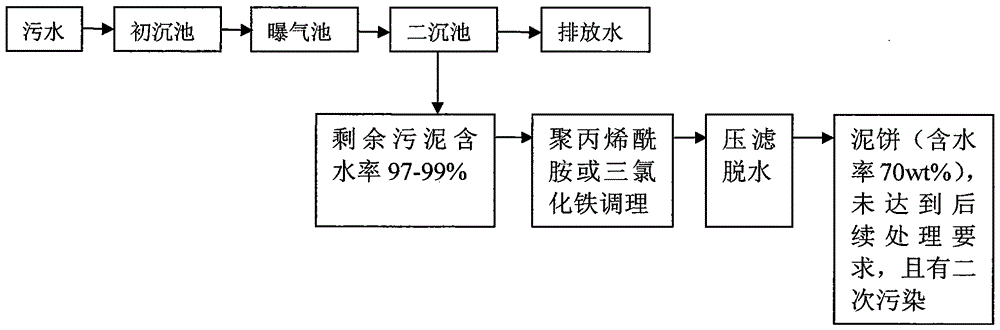

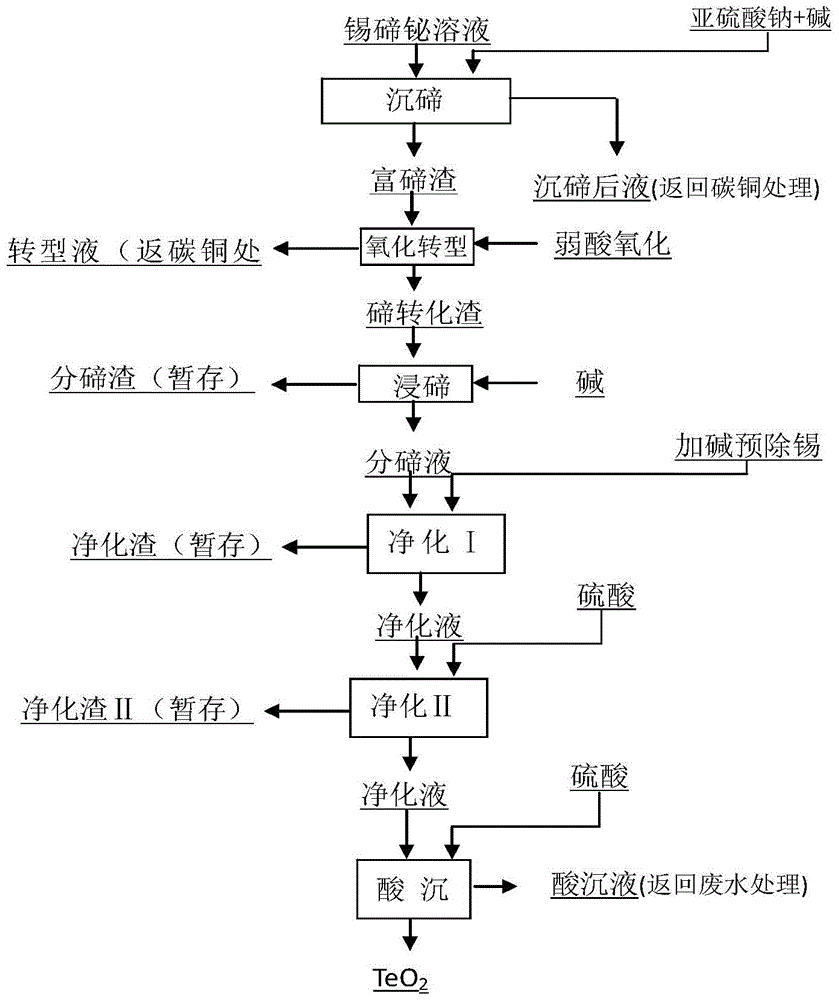

A method of applying natural friendly compound conditioner to realize efficient dehydration of sludge

InactiveCN104326642BNo corrosionEasy to handleSludge treatment by de-watering/drying/thickeningSlagCompost

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

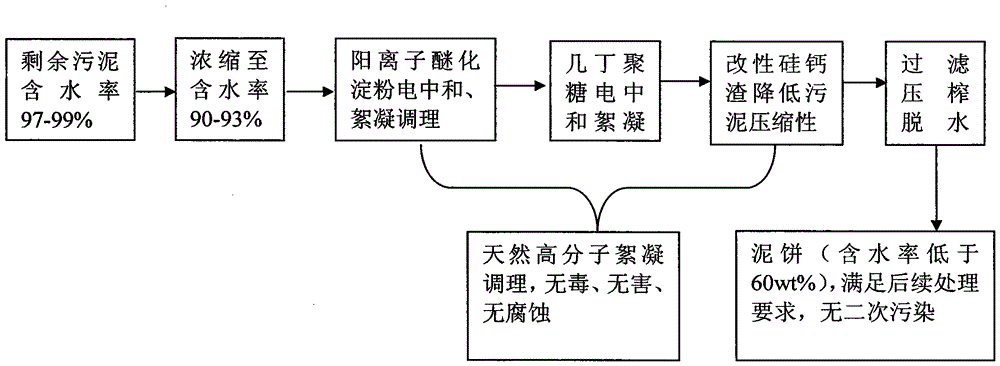

A kind of method for separating element from tin-containing bismuth tellurium solution

ActiveCN104651618BDowngradeHigh spent acid concentrationProcess efficiency improvementElemental selenium/telluriumHigh concentrationRefining (metallurgy)

The invention discloses a method for separating elements from a tin-tellurium-bismuth containing solution, and belongs to hydrometallurgy. Because of the low content and low grade of tin, tellurium and bismuth, tin, tellurium and bismuth in the tin-tellurium-bismuth containing solution cannot be economically recycled when basic cupric carbonate is produced along with wastewater treatment at present, and the resources can be greatly wasted. The method comprises the following steps: adding an industrial waste liquid containing multiple components, appropriately adjusting the pH value, primarily separating from other base metals, performing oxidation conversion treatment on the obtained tellurium enriched product so as to obtain a secondary enriched product, further leaching tin and bismuth by using low-concentration sodium hydroxide strong base, and separating tin by using high-concentration sodium hydroxide strong base, thereby obtaining a high-grade crude tin product, adjusting the pH value of a tellurium solution by using a diluted acid, and removing impurities such as tin and lead for a second time, thereby obtaining high-grade tellurium dioxide, providing the high-grade tellurium dioxide to a tellurium refining plant for refining tellurium, and extracting other elements from converted slag which is rich in bismuth and silver. The method is free of dispersion in the tellurium extraction process, has the advantages of high tellurium recycling rate and direct yield, is good in tin and bismuth separation effect and is applicable to treatment on low-concentration tin-tellurium-bismuth containing solutions.

Owner:JIANGXI COPPER

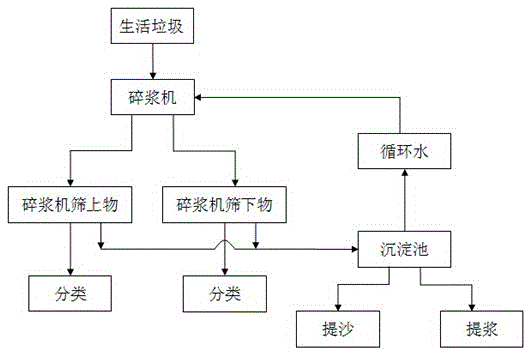

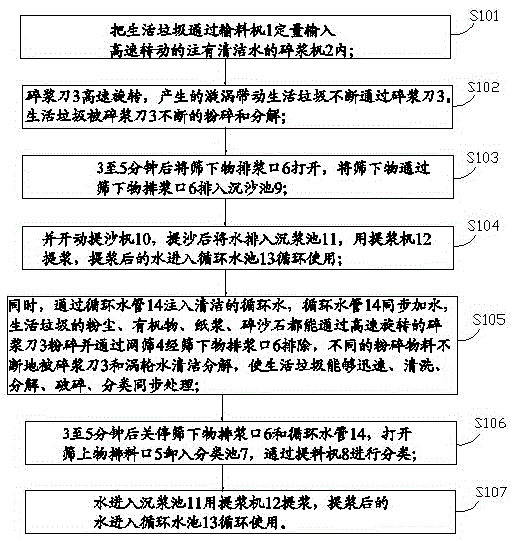

Domestic waste treatment system and its treatment method

InactiveCN104138891BCategory Synchronization Processing SynchronizationSuitable for large-scale processingSolid waste disposalDecompositionChest side

Owner:GUANGZHOU ZHENGLV ENVIRONMENTAL PROTECTION TECH CO LTD

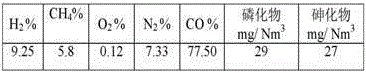

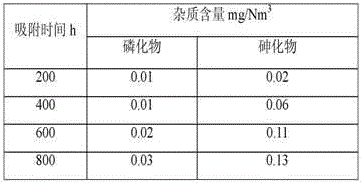

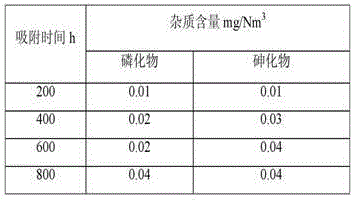

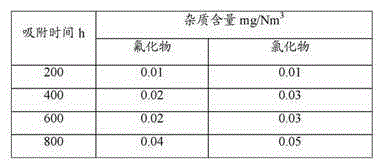

Purifying agent for removing phosphorus and arsenic in calcium carbide furnace tail gas and its preparation method and application

ActiveCN103551030BWide pore size distributionEfficient removalDispersed particle separationResource utilizationCleansing Agents

The invention discloses a cleaning agent for removing phosphorous and arsenic in calcium carbide furnace exhaust. The cleaning agent is prepared by the processes of taking A-X combined zeolite as a vector and loading an active metal component for removing phosphorous and arsenic by a kneading method. Compared with the prior art, the cleaning agent disclosed by the invention takes metals such as copper, molybdenum, ferrum and zinc as active components, and takes the A-X combined zeolite as the vector, so that the aperture of an adsorption layer of the cleaning agent is wider in distribution, and the cleaning agent has a good absorption effect on different apertures of phosphides and arsenides. The cleaning agent disclosed by the invention is efficient and fast; effective removal of heavily contaminated materials such phosphides and arsenides in the calcium carbide furnace exhaust can be simultaneously achieved at normal temperature; the phosphorous content and arsenic content in the purified calcium carbide furnace exhaust are smaller than or equal to 0.1 mg / Nm<3>; the resource utilization of carbon monoxide can be completely met.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

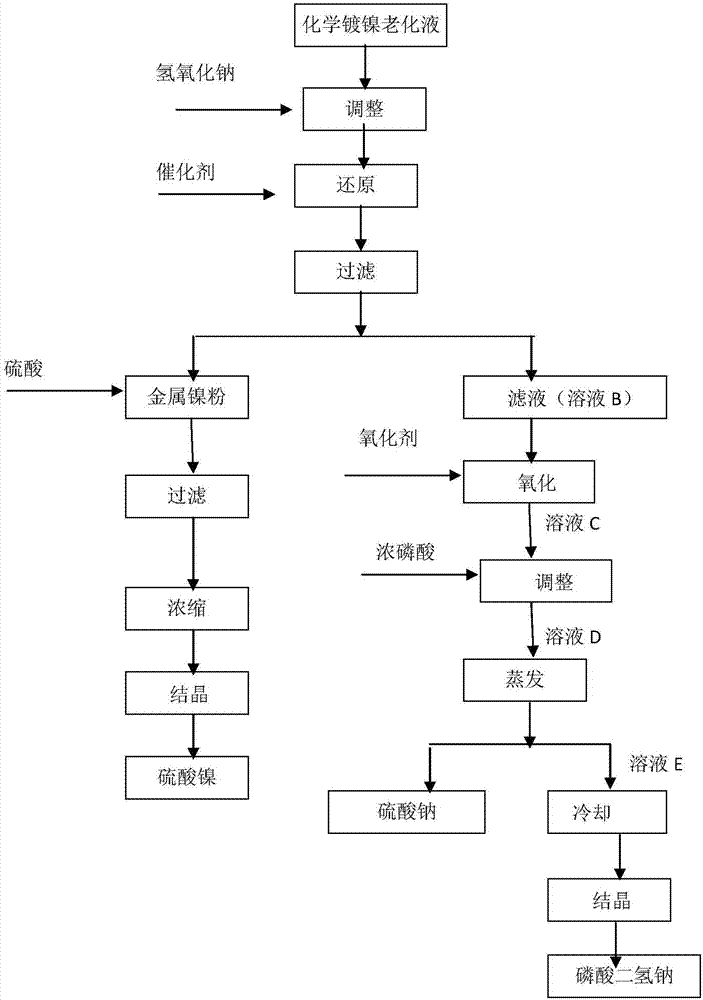

A kind of nickel plating aging solution prepares the method for metal nickel sulfate, sodium dihydrogen phosphate and sodium sulfate

ActiveCN106241897BResource utilizationNickel sulfatesPhosphorus compoundsAcid dissolutionSodium sulfate

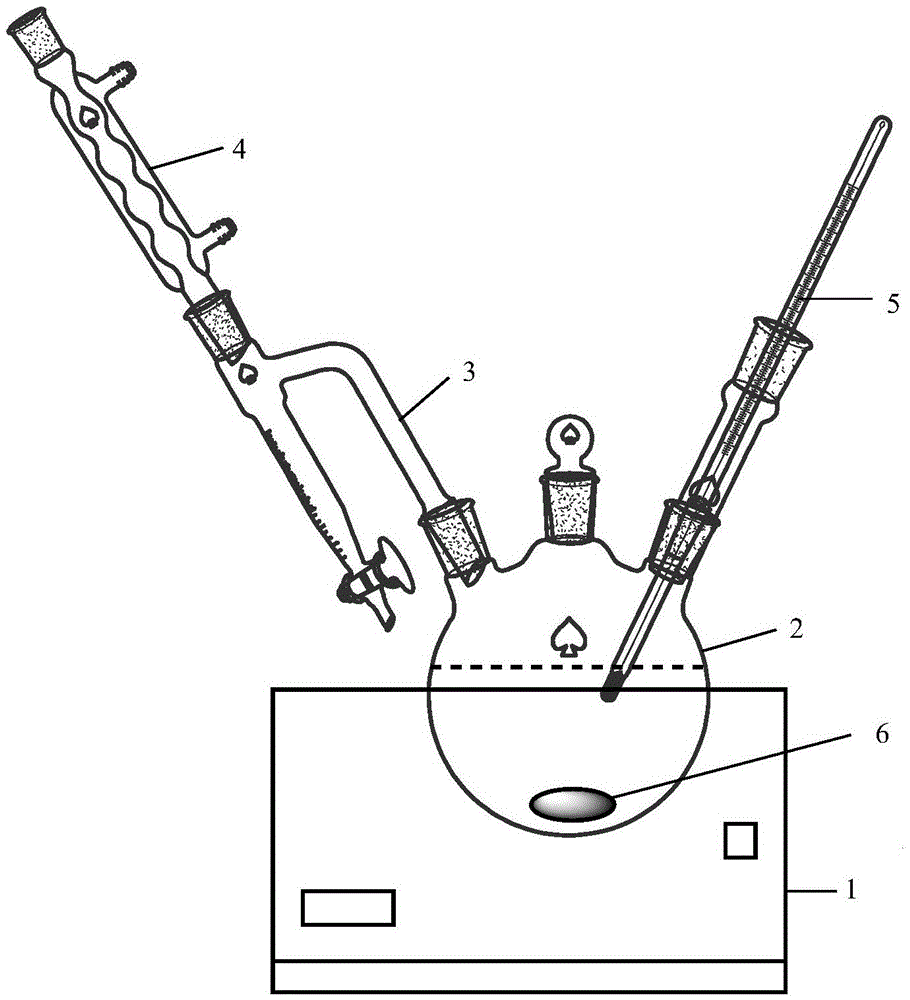

The invention provides a method for preparing metal nickel sulfate, sodium dihydrogen phosphate and sodium sulfate by using a nickel plating aging liquid. The method comprises: (1) adjusting the pH value of a nickel plating aging liquid by using an alkali, and carrying out thermal insulation to obtain a solution A; (2) stirring the solution A, adding a catalyst, and filtering to obtain metal nickel powder and a solution B; (3) adding sulfuric acid to the metal nickel powder to dissolve, adding hydrogen peroxide, and carrying out filtration concentration crystallization to obtain the nickel sulfate product; (4) adding an oxidizing agent to the solution B to obtain a solution C; (5) adding a concentrated acid to the solution C and adjusting the pH value to obtain a solution D; (6) evaporating and crystallizing the solution D, and filtering to obtain the sodium sulfate product and a solution E; and (7) continuously concentrating the solution E, carrying out cooling crystallization, and filtering to obtain the sodium dihydrogen phosphate product, wherein the mother liquor returns to the next batch so as to be continuously concentrated and used. According to the present invention, the treatment process is easy to achieve, no secondary waste is produced, the three products such as nickel sulfate, sodium dihydrogen phosphate and sodium sulfate can be obtained at the same time, and the good economic benefits and the good environmental benefits are provided.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

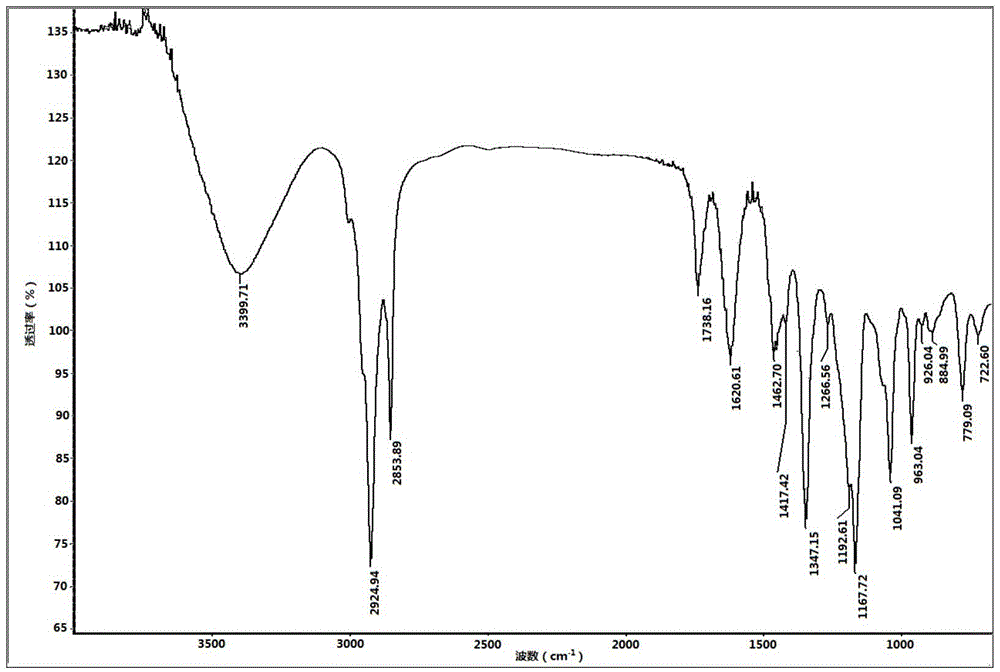

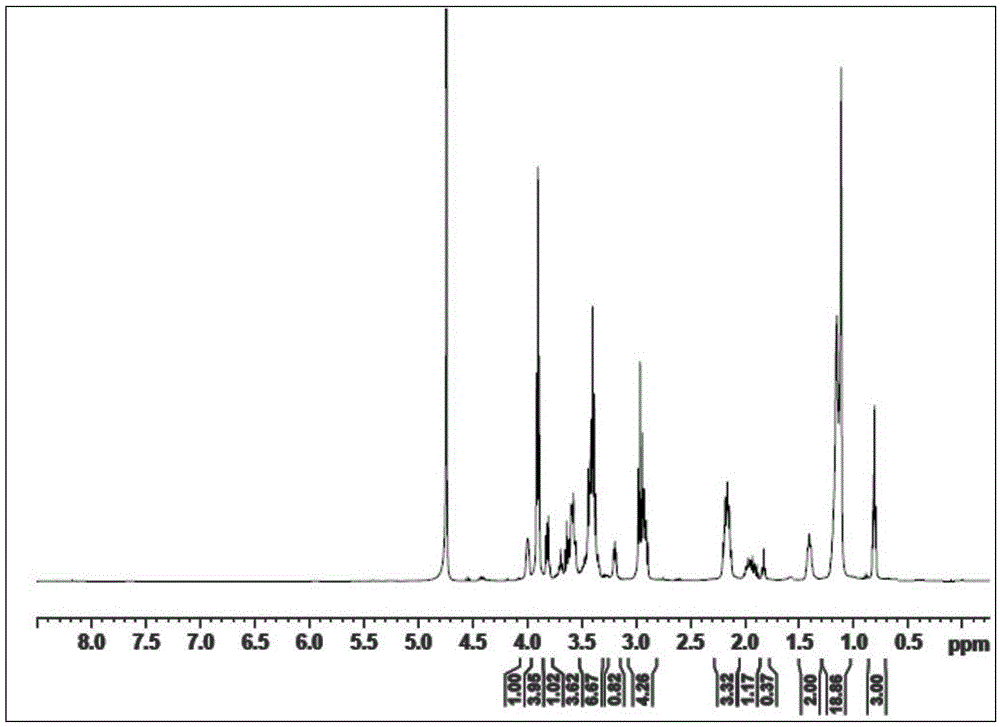

Sulfonate type biomass surfactant and synthesis method thereof

ActiveCN103805155BImprove surface activityHigh interface activitySulfonic acids salts preparationDrilling compositionSynthesis methodsWaste oil

The present invention relates to the field of organic compound synthesis, and specifically, relates to a sulfonate-type biomass surfactant based on a fatty acid methyl ester and a synthesis method thereof. A main component of city restaurant and kitchen swill waste oil is the fatty acid methyl ester. The sulfonate-type biomass surfactant based on the fatty acid methyl ester is prepared from the following steps: preparing fatty acid alkanolamide, and carrying out a sulfopropyl reaction. The sulfonate-type biomass surfactant based on the fatty acid methyl ester is applied in the field of oil production. The sulfonate-type biomass surfactant synthesized in the present invention has better surface activity and interfacial activity, is non-toxic, non-hazardous and degradable, does less harm to an environment and a stratum layer, can replace a conventional petroleum diesel-based surfactant, achieves purposes of resourceful comprehensive utilization of city restaurant and kitchen swill and added value improvement, and has a good application prospect; in addition, a synthesis reaction condition is mild, a preparation process is simple, and the process is reasonable, applying to scale production; the surfactant is used as an oil washing agent of a chemical flooding system in oil drilling, improves an oil washing effect, and thus improves a crude oil recovery rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

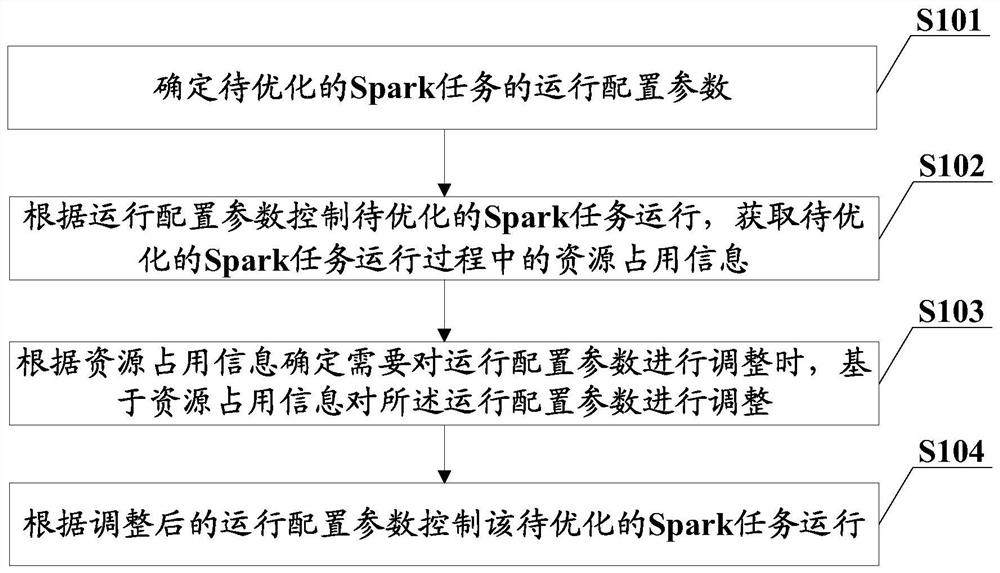

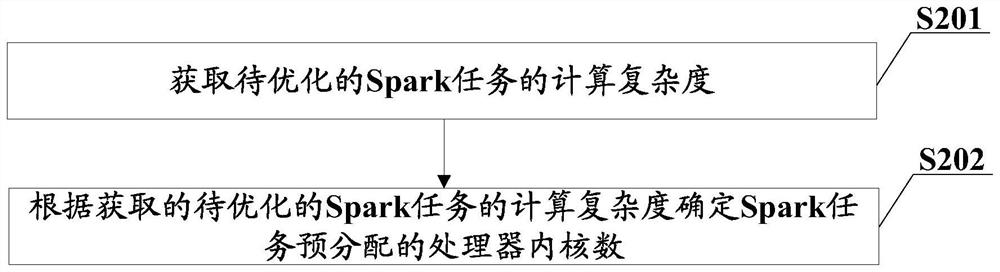

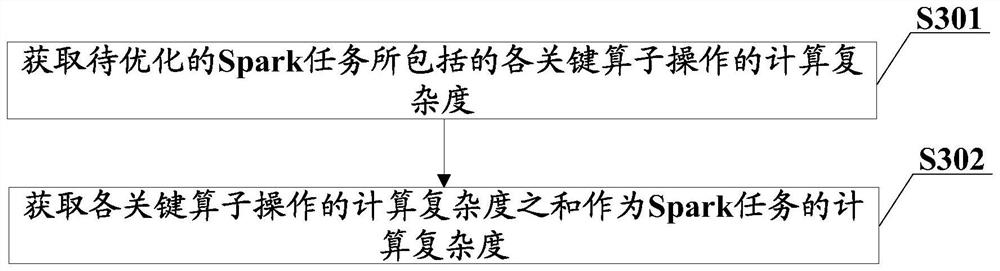

Spark performance optimization control method, device and equipment and storage medium

PendingCN112379935AImprove performanceResource utilizationResource allocationProgram loading/initiatingProcess engineeringParameter control

Owner:ZTE CORP

A kind of method for purification and treatment of waste water from vanadium extraction by wet method

ActiveCN109205873BSimple stepsWeight increaseWater contaminantsTreatment involving filtrationPurification methodsSlag

Owner:宜昌银钒科技有限公司

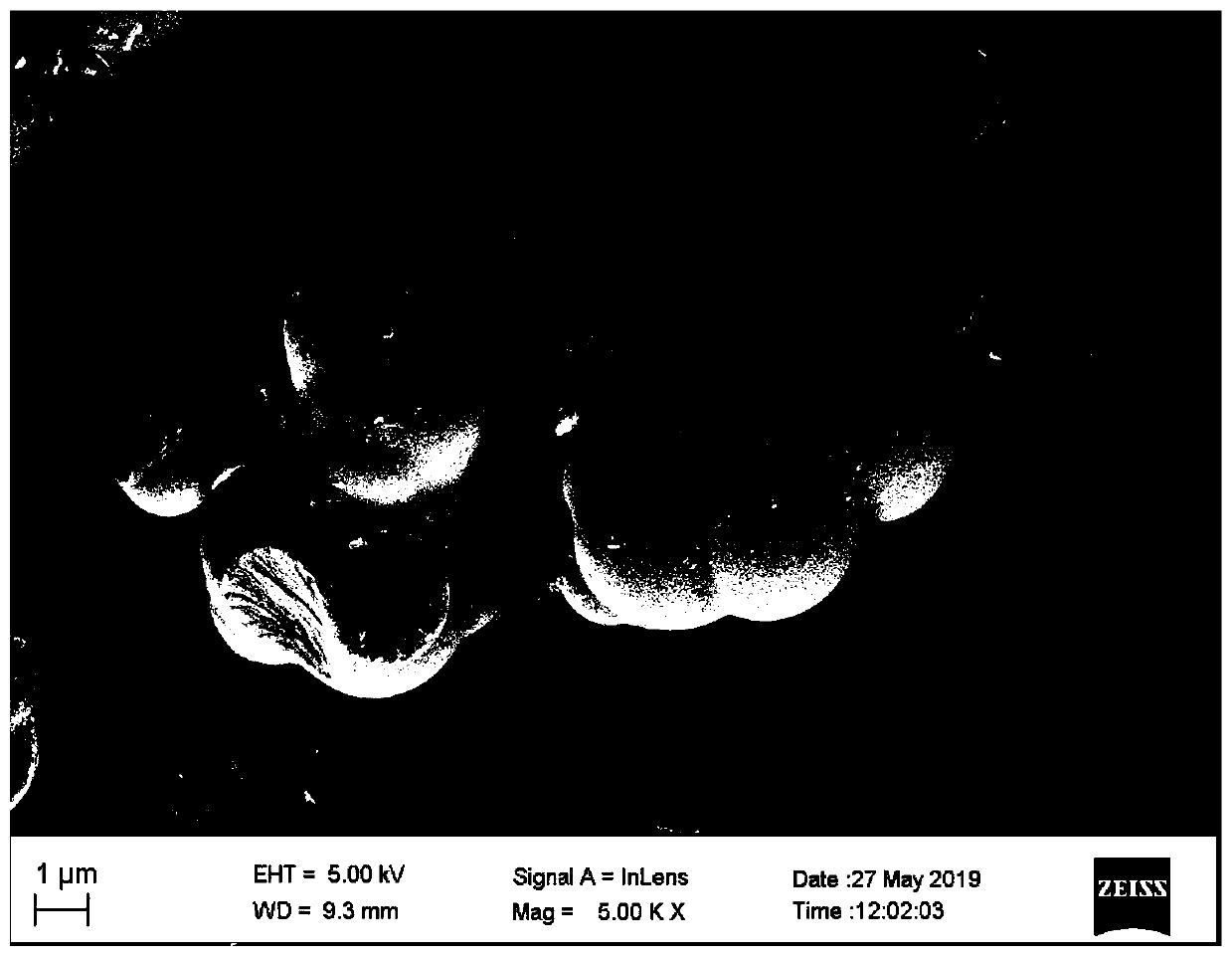

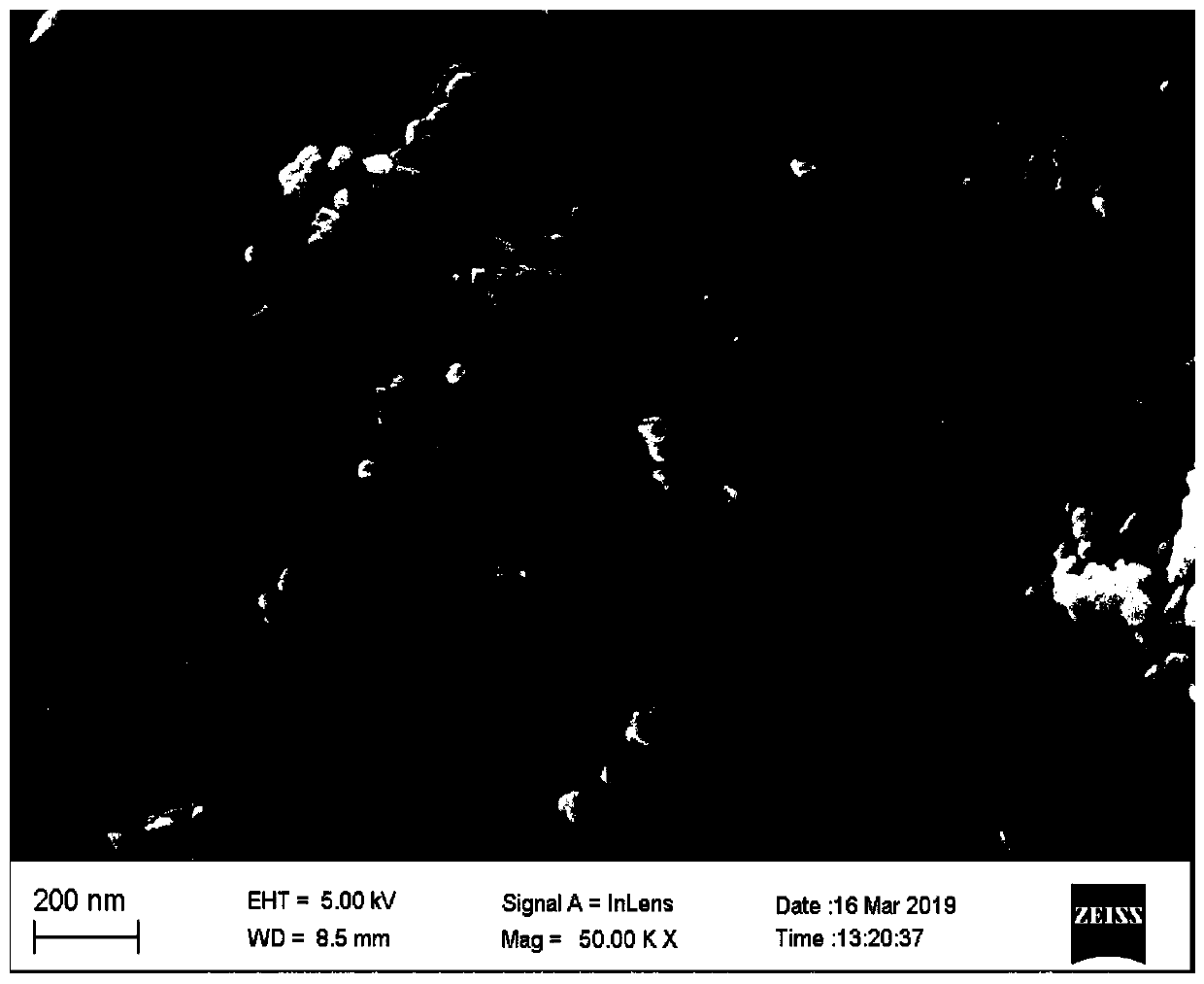

Starch carbide/sepiolite composite material and preparation method thereof

PendingCN110665459ALarge specific surface areaIncrease contact areaOther chemical processesWater contaminantsPtru catalystFreeze-drying

The invention discloses a starch carbide / sepiolite composite material and a preparation method thereof. The preparation method comprises the following steps: dissolving a catalyst in water, adding starch and sepiolite, uniformly mixing, carrying out hydrothermal carbonization reaction, carbonizing the starch to form carbon microspheres, loading the carbon microspheres on the surface of the sepiolite, and carrying out vacuum freeze drying to obtain the starch carbide / sepiolite composite material. The composite material disclosed by the invention is large in specific surface area and good in adsorption effect on organic pollutants, and the adsorption capacity on methylene blue reaches 39.36 mg / g or above and is improved by 12.04% or above compared with the adsorption effect of a sepiolite raw material; the preparation method has the advantages of simplicity, mild reaction conditions, low raw material cost, facilitation of realization of the high added value of sepiolite, and good application prospect.

Owner:GUANGXI UNIV FOR NATITIES

A method and device for monitoring and managing an assembly line

InactiveCN103197623BEasy to findReduce cloggingProgramme total factory controlDisplay deviceAssembly line

The invention relates to a method and a device of assembly line monitoring management. The method includes the following steps that state data of each product in the assembly line in each process are collected, a server calculates location information of each product in each process according to the collected state data, a display device displays the location of each product in each process in the assembly line according to the location information, the server simulates the location of each product in each process in the assembly line according to the location information, actual residence time and standard process time are obtained, when the actual residence time is out of a preset value range, the number of processes in the simulation process in the step 4 is adjusted to obtain a final simulation status, and the number of stations and the number of operating personnel in the processes in the actual assembly line are set according to the final simulation status. According to the method and the device of the assembly line monitoring management, the problems in the assembly line can be discovered timely and conveniently, resources of all processes can be used to a maximum degree, stoppage and waiting time of the assembly line are reduced, and production efficiency is improved.

Owner:张舒

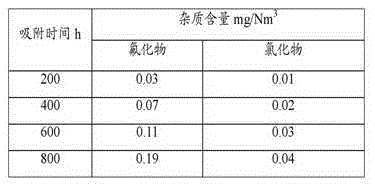

Purifying agent for removing fluorine and chlorine in calcium carbide furnace tail gas and its preparation method and application

ActiveCN103551106BWide pore size distributionEfficient removalOther chemical processesCarbon monoxideCeriumEngineering

The invention discloses a cleaning agent for removing fluorine and chlorine in calcium carbide furnace exhaust. The cleaning agent is prepared by the processes of taking A-X combined zeolite as a carrier and loading an active metal component for removing fluorine and chlorine by a kneading method. Compared with the prior art, the cleaning agent disclosed by the invention takes metals such as silver, cerium, nickel and cobalt as active components, and takes the A-X combined zeolite as the carrier, so that the aperture of an adsorption layer of the cleaning agent is wider in distribution, and the cleaning agent has a good absorption effect on fluorides and chlorides with different apertures. The cleaning agent disclosed by the invention is efficient and fast; effective removal of heavily contaminated materials such the fluorides and the chlorides in the calcium carbide furnace exhaust can be simultaneously achieved at normal temperature; the fluorine content and chlorine content in the cleaned exhaust are smaller than or equal to 0.1 mg / Nm<3>; the resource utilization of carbon monoxide can be completely met.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

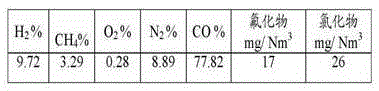

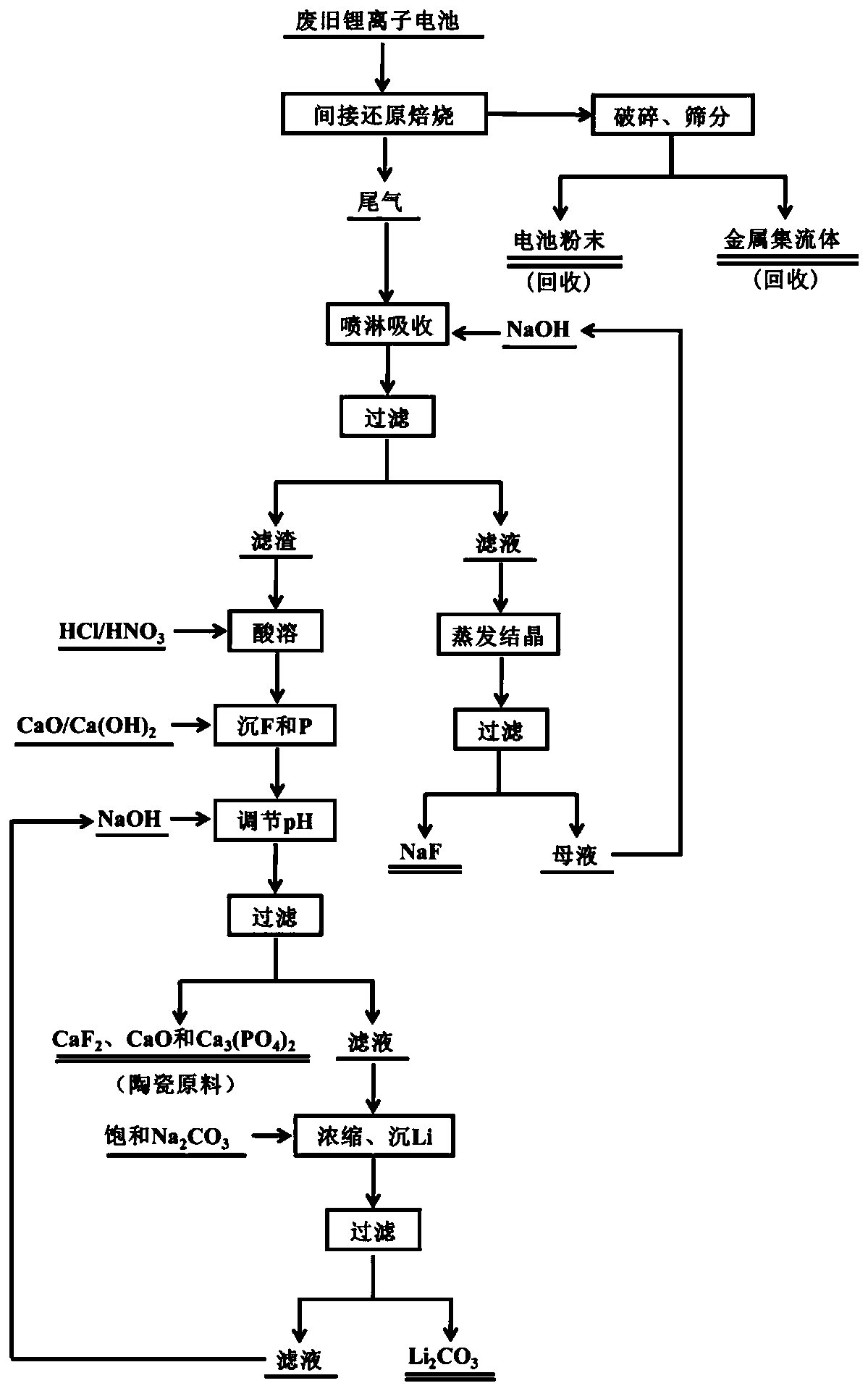

A method for resource utilization of waste lithium-ion battery roasting tail gas

ActiveCN110092398BHigh purityLow costWaste accumulators reclaimingAlkali metal fluoridesPhosphoric acidEngineering

The invention discloses a method for the resource utilization of waste lithium ion battery roasting tail gas. Indirect reduction roasting is performed on waste lithium ion batteries in a rotary kiln,and battery powder and metal current collectors which are used for the recycling of follow-up processes after roasting, crushing and sieving; after tail gas generated during roasting is absorbed through the spraying of an alkaline solution, mixed filter residues of lithium phosphate and lithium fluoride and sodium fluoride containing filtrate can be obtained through filtering; a sodium fluoride product and crystallization mother liquor can be obtained after the evaporation, crystallization and filtration of the filtrate, and the crystallization mother liquor can return to be absorbed through spraying; calcium oxide or calcium hydroxide is added to precipitate fluorine and phosphor after the acid dissolution of the filter residues, mixed filter residues of calcium fluoride, calcium oxide and calcium phosphate which can be used as ceramic raw materials and lithium containing filtrate can be obtained after filtering; and a lithium carbonate product and alkaline filtrate are obtained afterthe concentration, lithium precipitation and filtering of the filtrate, and the alkaline filtrate can return back to the alkaline solution to adjust the pH of the solution. The method is simple in technology, short in process and low in reagent cost, and secondary pollution cannot be generated, so that the recycling problems of fluorine, phosphor and lithium in waste lithium ion battery roastingtail gas can be effectively solved.

Owner:GUANGDONG GUANGHUA SCI TECH

Grading optimization method of waste asphalt concrete based on gray system theory

InactiveCN104496284BImprove road performanceImprove high temperature stabilitySolid waste managementForecastingPorosityEffective factor

The invention discloses a waste asphalt concrete gradating optimization method based on grey system theory, belonging to the material technical field. The method includes performing grading pre-treatment of waste asphalt concrete, building virtual screen size gradation among each grade of waste asphalt concrete direct screening results and the screening results after removal of asphalt, preparing macroporous asphalt concrete under the condition of different virtual screen size gradation blending proportions, performing grey relational analysis and grey correlation degree ordering by adopting porosity deviation changes of macroporous asphalt concrete as the main behavior of the system, and proportional changes of different virtual coefficients in synthesis screening as an effective factor affecting the main behavior, and choosing the virtual screen size gradation with maximum correlation as mixture ratio design basis of actual production of recycled asphalt concrete. The method can accurately control the mixture ratio design of the recycled asphalt concrete, improve recycled asphalt concrete performance, and provide theoretical guidance for application of the waste asphalt concrete in skeleton asphalt mixture.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com