A method of applying natural friendly compound conditioner to realize efficient dehydration of sludge

A friendly, conditioning agent technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of sludge treatment capacity decline, direct discharge, metal environmental hazards, etc., to achieve Realize the utilization of resources, improve the processing capacity, and improve the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

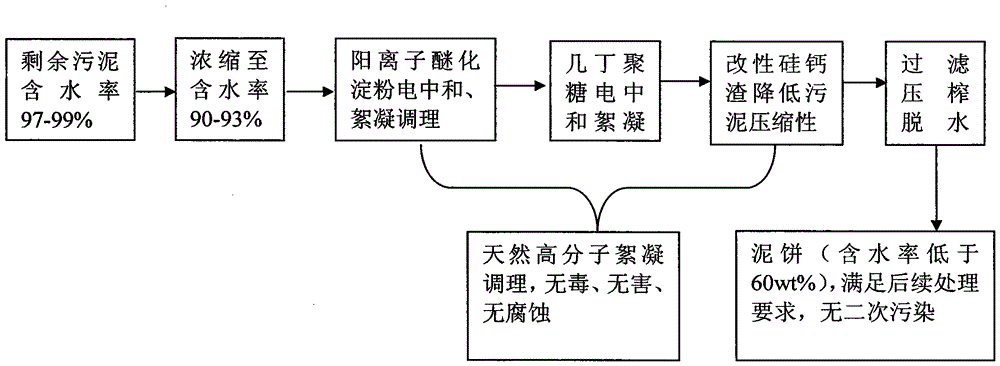

[0024] The water content of the remaining sludge at the bottom of the secondary settling tank is 97-99%, a method of using a natural and friendly compound conditioner to achieve high-efficiency sludge dehydration, and its technical route is as follows figure 2 As shown, the specific steps are as follows:

[0025] (1) Concentrate and dehydrate the sludge to a moisture content of 90-93% by using a horizontal spiral sedimentation centrifuge;

[0026] (2) Add an aqueous solution of cationic etherified starch to the sludge suspension with a water content of 90-93%, and mechanically stir for 5 minutes to ensure that the electrical neutralization reaction is fully carried out; addition amount: cationic etherified starch and sludge The mass ratio of solid phase is 0.2%: 1;

[0027] (3) Add the acetic acid solution of chitosan and mechanically stir for 10 minutes to ensure that the long-chain molecules of chitosan form a strong bridging effect with the sludge flocs and particles, the...

Embodiment 2

[0033] The water content of the remaining sludge at the bottom of the secondary settling tank is 97-99%, a method of using a natural and friendly compound conditioner to achieve high-efficiency sludge dehydration, and its technical route is as follows figure 2 As shown, the specific steps are as follows:

[0034] (1) Concentrate and dehydrate the sludge to a moisture content of 90-93% by using a horizontal spiral sedimentation centrifuge;

[0035] (2) Add an aqueous solution of cationic etherified starch to the sludge suspension with a water content of 90-93%, and mechanically stir for 5 minutes to ensure that the electrical neutralization reaction is fully carried out. Addition amount: cationic etherified starch and sludge The mass ratio of solid phase is 0.5%: 1;

[0036] (3) Add the acetic acid solution of chitosan and mechanically stir for 10 minutes to ensure that the long-chain molecules of chitosan form a strong bridging effect with the sludge flocs and particles, the...

Embodiment 3

[0042] The water content of the remaining sludge at the bottom of the secondary settling tank is 97-99%, a method of using a natural and friendly compound conditioner to achieve high-efficiency sludge dehydration, and its technical route is as follows figure 2 As shown, the specific steps are as follows:

[0043] (1) Concentrate and dehydrate the sludge to a moisture content of 90-93% by using a horizontal spiral sedimentation centrifuge;

[0044] (2) Add an aqueous solution of cationic etherified starch to the sludge suspension with a water content of 90-93%, and mechanically stir for 5 minutes to ensure that the electrical neutralization reaction is fully carried out. Addition amount: cationic etherified starch and sludge The mass ratio of solid phase is 0.75%: 1;

[0045] (3) Add the acetic acid solution of chitosan and mechanically stir for 10 minutes to ensure that the long-chain molecules of chitosan form a strong bridging effect with the sludge flocs and particles, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com