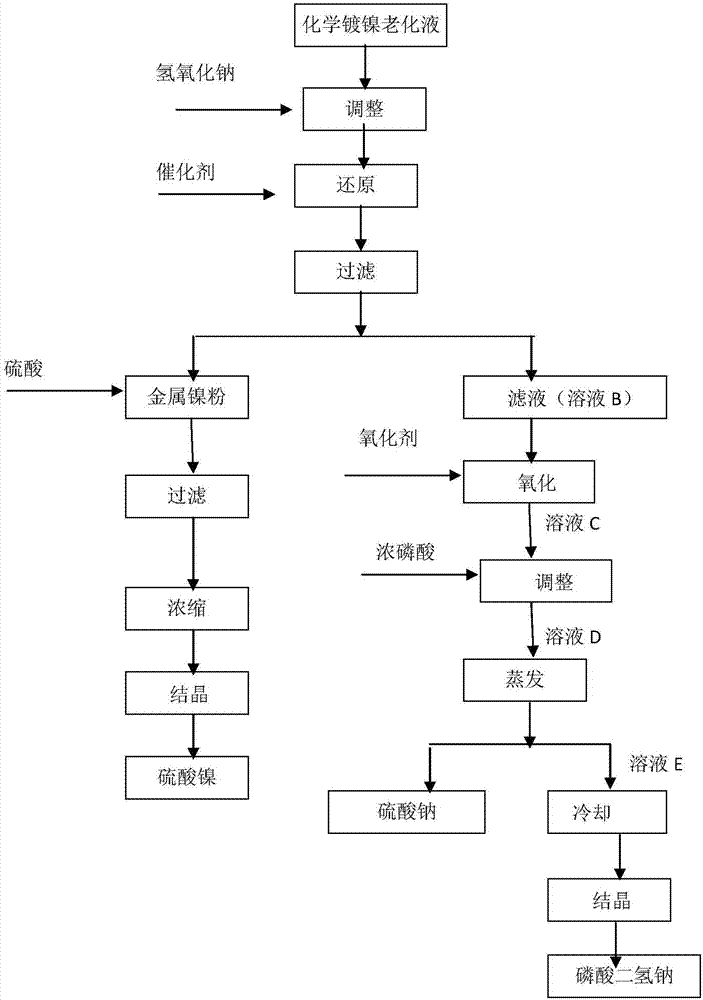

A kind of nickel plating aging solution prepares the method for metal nickel sulfate, sodium dihydrogen phosphate and sodium sulfate

A technology of sodium dihydrogen phosphate and aging solution, which is applied in the fields of alkali metal sulfite/sulfite, chemical instruments and methods, nickel sulfate, etc., and can solve problems such as use risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 1000mL of electroless nickel plating aging solution from the production line of a PCB manufacturer, add caustic soda to adjust pH=8, exothermic temperature rises to 80°C during the process, and keep it warm for 80min to obtain solution A; solution A is stirred, and the final concentration is 0.5wt% Activated carbon powder, metal nickel powder and solution B will be obtained, and 2g of metal nickel powder will be obtained by filtration; and 1% hydrogen peroxide will be added, after dissolution is complete, filtered, concentrated and crystallized to obtain 0.5g of nickel sulfate product; in solution B, add persulfuric acid 10g, stirred for 30 minutes, the remaining sodium dihydrogen phosphite and sodium dihydrogen hypophosphite in the aging solution can be converted into sodium dihydrogen phosphate, which is solution C; add concentrated phosphoric acid to solution C to adjust pH=4 , to obtain solution D; solution D is evaporated and crystallized at a controlled temper...

Embodiment 2

[0028] Take 1000mL of electroless nickel plating aging solution from the production line of a PCB manufacturer, add caustic soda to adjust pH=10, exothermic temperature rises to 90°C during the process, and keep warm for 60min to obtain solution A; solution A is stirred, and the final concentration is 0.1wt% Activated carbon powder, metal nickel powder and solution B will be obtained, and 3g of metal nickel powder will be obtained by filtration; and 3% hydrogen peroxide will be added, after dissolution is complete, filtered, concentrated and crystallized to obtain 1g of nickel sulfate product; in solution B, add 20g of persulfuric acid , stirred for 30 minutes, the residual sodium dihydrogen phosphite and sodium dihydrogen hypophosphite in the aging solution can be converted into sodium dihydrogen phosphate, which is solution C; add concentrated phosphoric acid to solution C to adjust pH=3, Obtain solution D; solution D is evaporated and crystallized, and the temperature is con...

Embodiment 3

[0030] Take 1000mL of electroless nickel plating aging solution from the production line of a PCB manufacturer, add caustic soda to adjust pH=11, exothermic temperature rises to 100°C during the process, and keep it warm for 50min to obtain solution A; solution A is stirred, and added with final concentration of 1wt% Activated carbon powder, metal nickel powder and solution B will be obtained, and 2g of metal nickel powder will be obtained by filtration; and 5% hydrogen peroxide will be added, after dissolution is complete, filtered, concentrated and crystallized to obtain 4g of nickel sulfate product; add iodine 15g to solution B, stir In 30 minutes, the residual sodium dihydrogen phosphite and sodium dihydrogen hypophosphite in the aging solution can be converted into sodium dihydrogen phosphate, which is solution C; add concentrated phosphoric acid to solution C, adjust pH = 5, and obtain a solution D; Evaporation and crystallization of solution D is carried out at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com