Starch carbide/sepiolite composite material and preparation method thereof

A composite material and sepiolite technology, which is applied in the field of starch carbide/sepiolite composite material and its preparation, can solve the problems of high energy consumption of thermal modification, environmental pollution, equipment corrosion, etc., and achieve controllable reaction and adsorption effect Good, fast response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

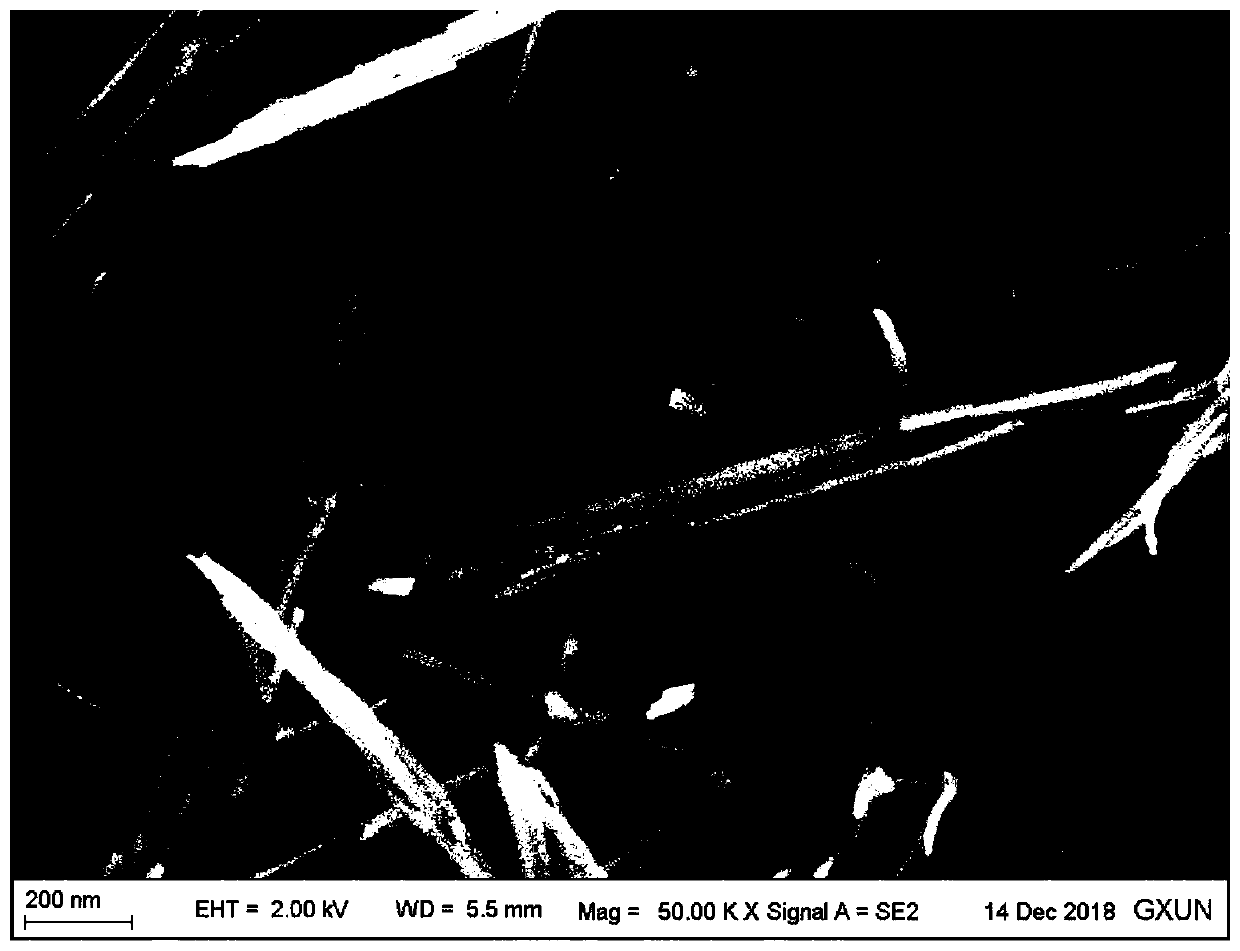

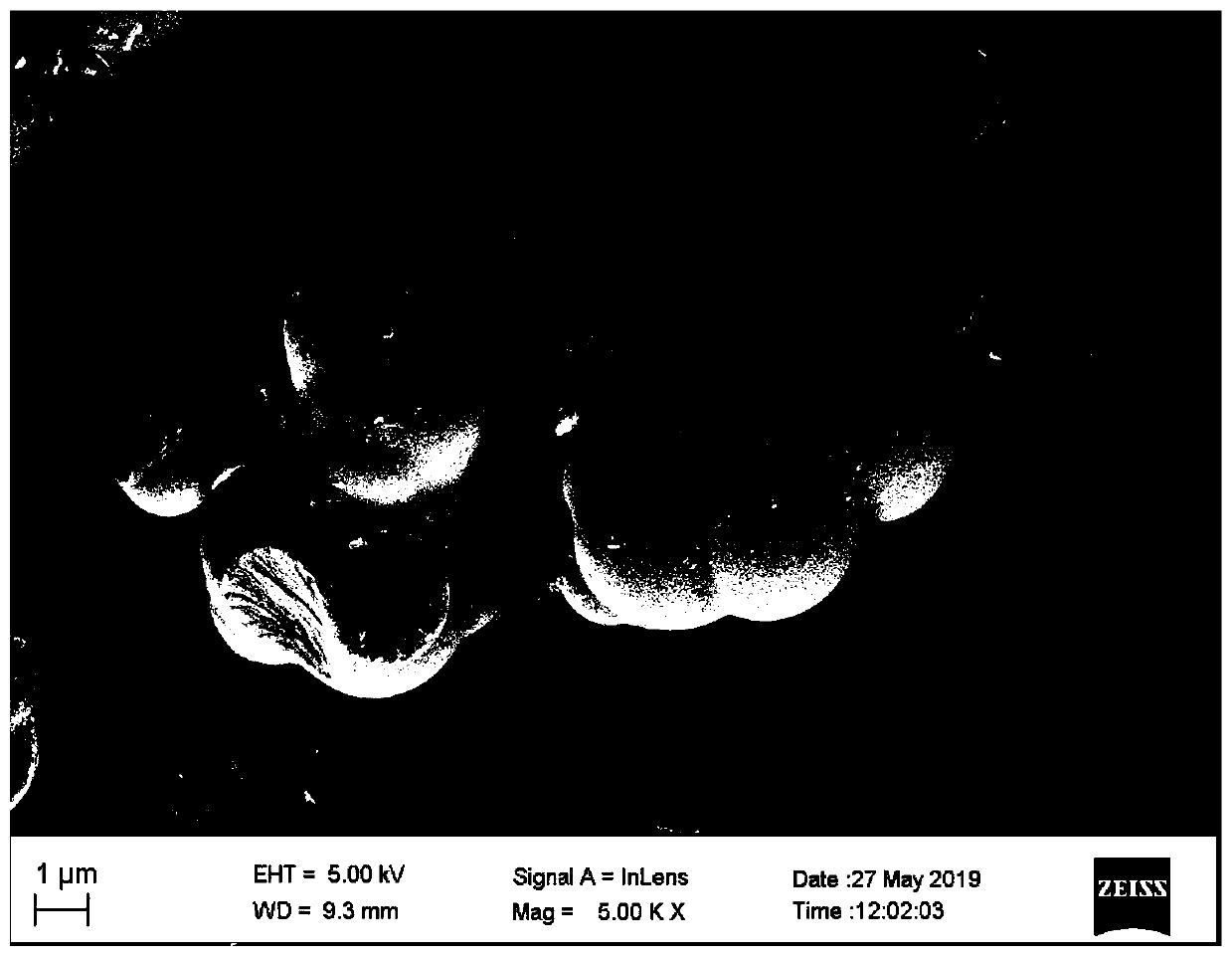

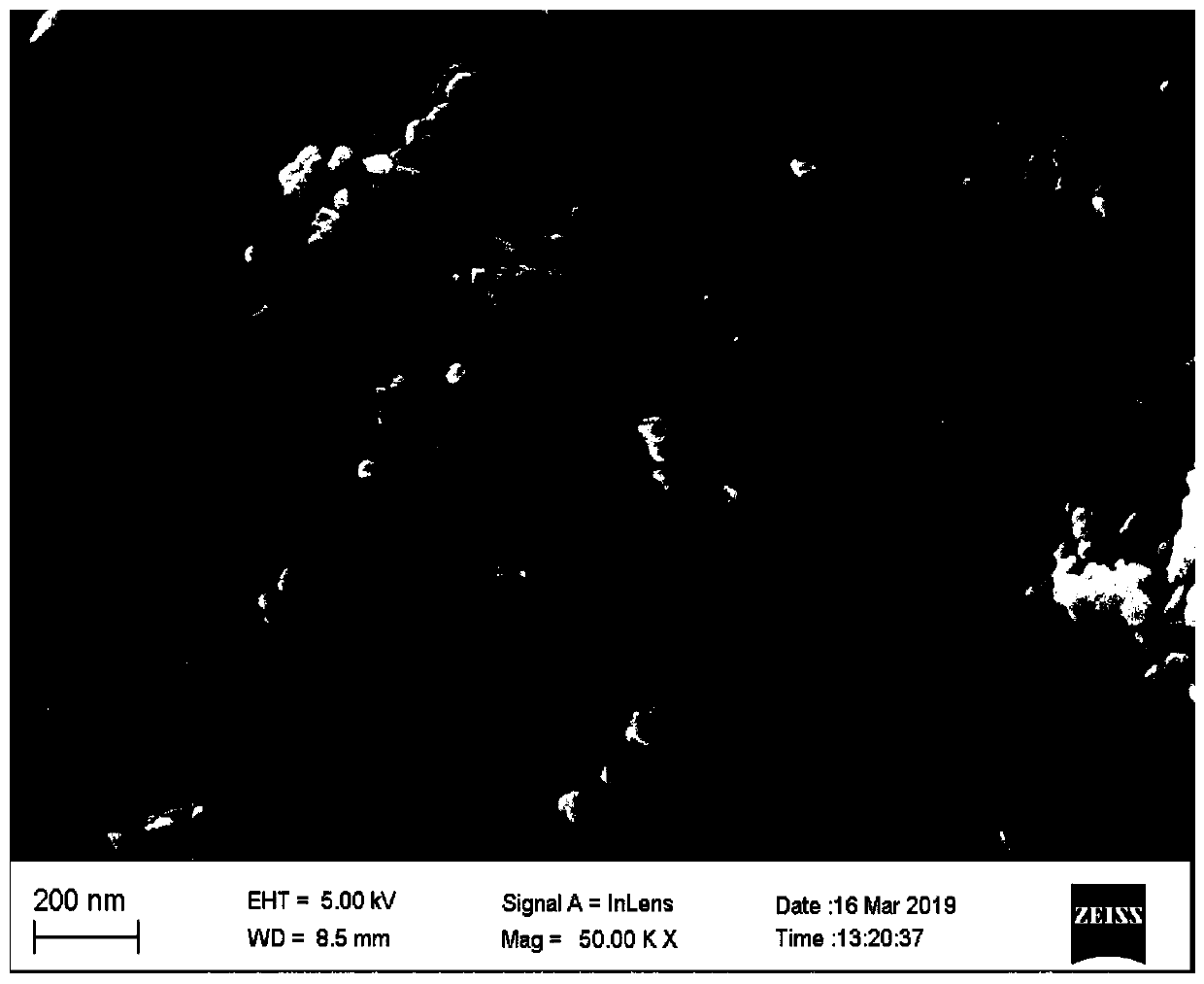

[0034] A kind of preparation method of starch carbide / sepiolite composite material, comprises the following steps:

[0035] (1) Add 0.5 g of ferrous ammonium sulfate hexahydrate into water, stir until dissolved, and obtain a catalytic solution.

[0036] (2) Disperse 8g of starch in water to obtain a starch solution, then add the starch solution and 5g of sepiolite to the catalytic solution, stir and disperse evenly, first stir at 600rpm for 1h, and then ultrasonically shake at 45kHz for 1h , to obtain a mixed suspension.

[0037] (3) The mixed suspension was placed in a stainless steel reactor for hydrothermal carbonization at a reaction temperature of 180° C. and a reaction time of 12 hours to obtain a brown solid substance.

[0038] (4) Alternately washing the brown solid matter with water and absolute ethanol until the filtrate is colorless, and then vacuum freeze-drying to obtain a starch carbide / sepiolite composite material.

Embodiment 2

[0040] A kind of preparation method of starch carbide / sepiolite composite material, comprises the following steps:

[0041] (1) Add 0.7 g of ferrous ammonium sulfate hexahydrate into water, stir until dissolved, and obtain a catalytic solution.

[0042] (2) Disperse 10g of starch in water to obtain a starch solution, then add the starch solution and 9g of sepiolite to the catalytic solution, stir and disperse evenly, first stir at 550rpm for 2.5h, and then ultrasonically oscillate at 47kHz After 1.3h, a mixed suspension was obtained.

[0043] (3) The mixed suspension was placed in a stainless steel reactor for hydrothermal carbonization at a reaction temperature of 170° C. and a reaction time of 16 hours to obtain a brown solid substance.

[0044] (4) Alternately washing the brown solid matter with water and absolute ethanol until the filtrate is colorless, and then vacuum freeze-drying to obtain a starch carbide / sepiolite composite material.

Embodiment 3

[0046] A kind of preparation method of starch carbide / sepiolite composite material, comprises the following steps:

[0047] (1) Add 0.3 g of ferrous ammonium sulfate hexahydrate into water, stir until dissolved, and obtain a catalytic solution.

[0048] (2) Disperse 5g of starch in water to obtain a starch solution, then add the starch solution and 1g of sepiolite to the catalytic solution, stir and disperse evenly, first stir at 500rpm for 1h, and then ultrasonically shake at 50kHz for 1h , to obtain a mixed suspension.

[0049] (3) The mixed suspension was placed in a stainless steel reactor for hydrothermal carbonization at a reaction temperature of 150° C. and a reaction time of 20 h to obtain a brown solid substance.

[0050](4) Alternately washing the brown solid matter with water and absolute ethanol until the filtrate is colorless, and then vacuum freeze-drying to obtain a starch carbide / sepiolite composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com