A method and device for monitoring and managing an assembly line

A monitoring management and assembly line technology, applied in electrical program control, comprehensive factory control, etc., can solve problems such as congestion, inability to optimize, and wait, so as to improve production efficiency and product quality, reduce blockage and waiting time, and reduce discovery. The effect of question time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

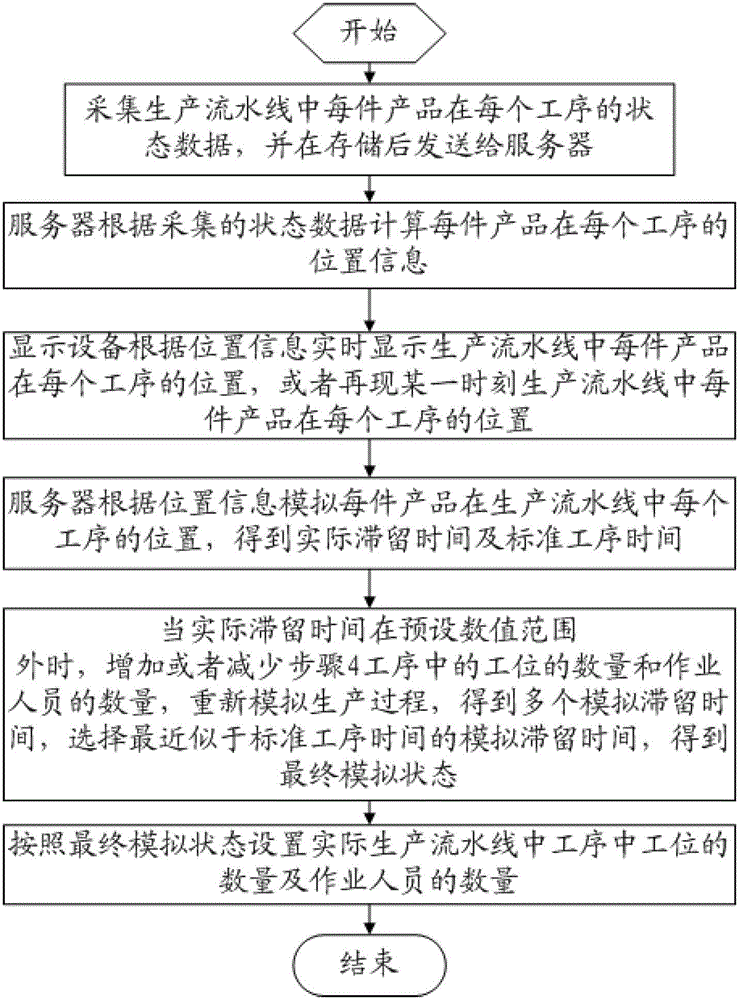

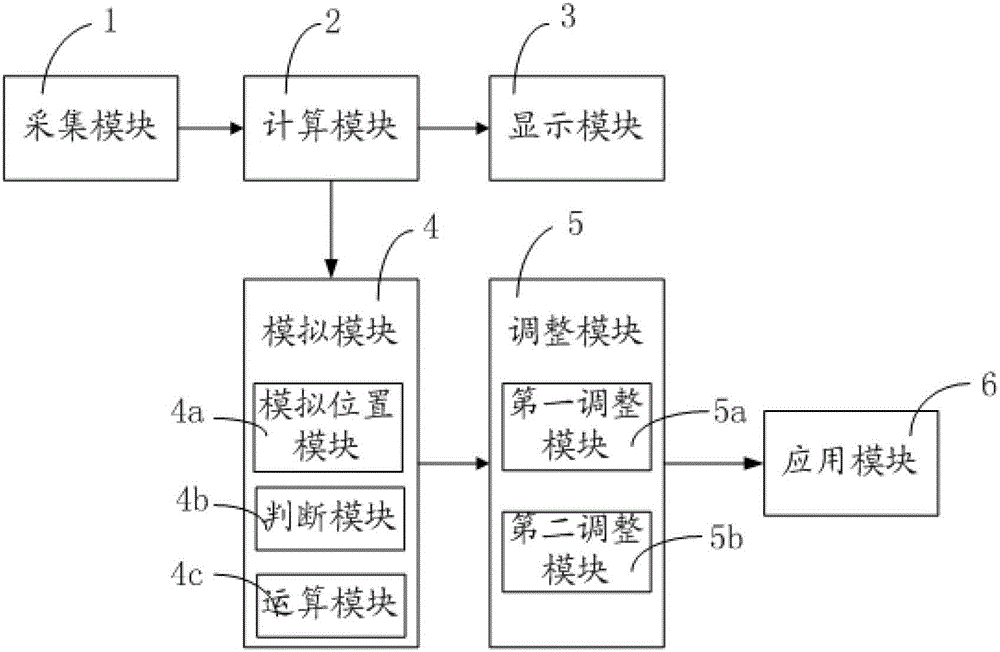

[0064] A production line simulation method, comprising the following steps:

[0065] Step 1: Collect the status data of each product in each process in the production line, and send it to the server after storage;

[0066] Step 2: The server calculates the position information of each product in each process according to the collected status data;

[0067] Step 3: The display device displays the position of each product in each process in the production line in real time according to the position information, or reproduces the position of each product in each process in the production line at a certain moment;

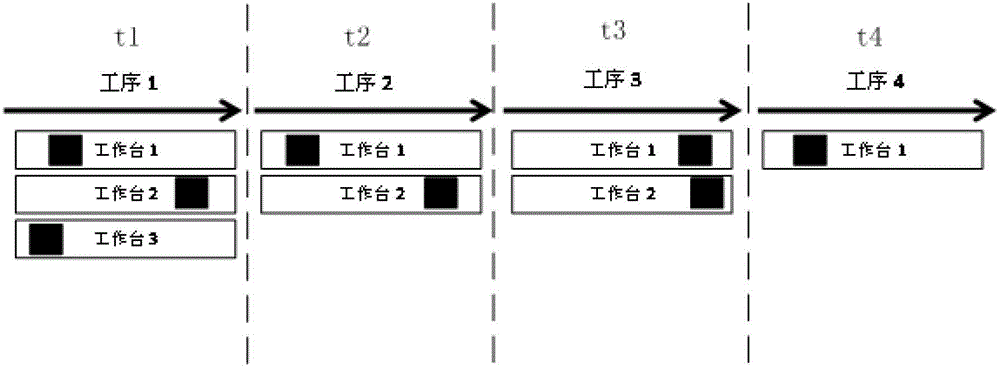

[0068] Step 4: The server simulates the position of each product in each process in the production line according to the position information, and obtains the actual retention time and standard process time;

[0069] Step 5: When the actual residence time is outside the preset value range, increase or decrease the number of stations and the number of workers in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com