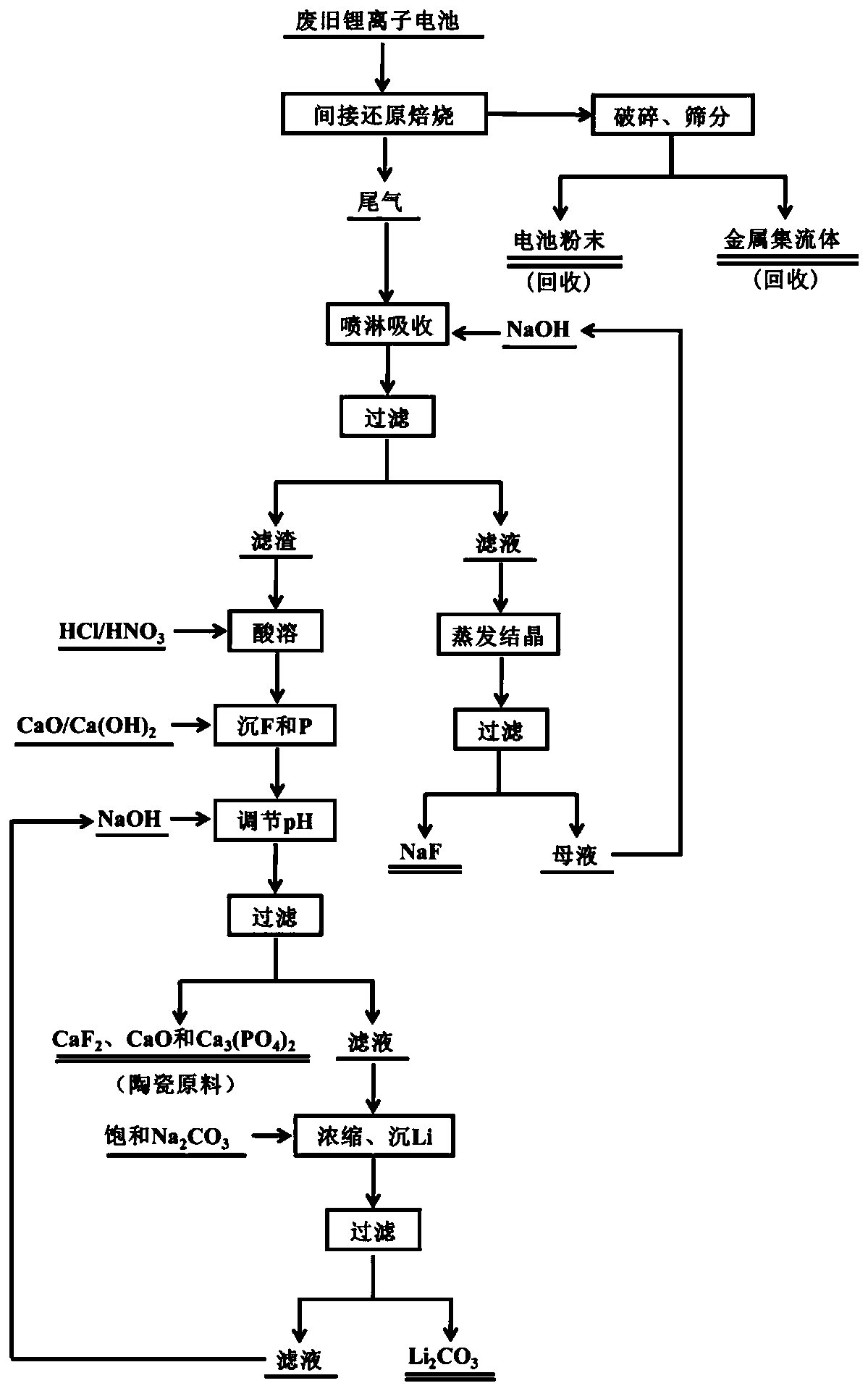

A method for resource utilization of waste lithium-ion battery roasting tail gas

A lithium-ion battery, resource-based technology, applied in battery recycling, recycling technology, alkali metal fluoride, etc., can solve secondary pollution resources, waste, not mentioned activated carbon and alkaline hydroxide or oxide recovery Treatment process and other problems, to achieve the effect of low energy consumption, low reagent cost, and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The waste lithium iron phosphate battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 500°C, and the roasting time was 2h. Use 1mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 8.0g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 120°C, and when the volume was evaporated to 31% of the volume of the original filtrate, it was filtered immediately, and the obtained filtrate was a crystal of sodium fluoride. Dissolve the filter residue with 6mol / L hydrochloric acid, add calcium oxide 1.2 times the total molar weight of F and P, and at the same time add 3mol / L sodium hydroxide to adjust the pH to 8.5, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lithium-contain...

Embodiment 2

[0023] The waste nickel-cobalt-manganese ternary battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 550°C, and the roasting time was 2h. Use 2mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 8.5g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 125°C, and when the volume was evaporated to 28% of the volume of the original filtrate, it was filtered immediately, and the filtrate obtained was a crystal of sodium fluoride. Dissolve the filter residue with 5 mol / L hydrochloric acid, add calcium oxide 1.3 times the total molar weight of F and P, and at the same time add 3 mol / L sodium hydroxide to adjust the pH to 9.5, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lith...

Embodiment 3

[0025] The waste lithium iron phosphate battery was placed in a rotary kiln for indirect reduction roasting, the roasting temperature was controlled at 500°C, and the roasting time was 2h. Use 1mol / L sodium hydroxide solution to spray and absorb the roasting tail gas to F - The concentration is 10.0g / L, and the filter residue containing lithium phosphate and lithium fluoride and the filtrate containing sodium fluoride are obtained by filtration. The filtrate was evaporated and crystallized at 110°C, and filtered immediately when the volume was evaporated to 36% of the volume of the original filtrate, and the obtained filtrate was a crystal of sodium fluoride. Dissolve the filter residue with 6mol / L hydrochloric acid, add calcium oxide 1.3 times the total molar weight of F and P, and at the same time add 3mol / L sodium hydroxide to adjust the pH to 9.0, and filter to obtain calcium fluoride, calcium oxide and calcium phosphate The mixed filter residue and lithium-containing fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com