Deep treatment method of pulping paper making wastewater

A technology for advanced treatment, pulping and papermaking, applied in the field of papermaking, can solve the problems of increasing pollutants, unfavorable waste water reuse, and high operating costs, and achieve the effects of simple and controllable process operation, satisfying resource utilization, and improving effluent color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

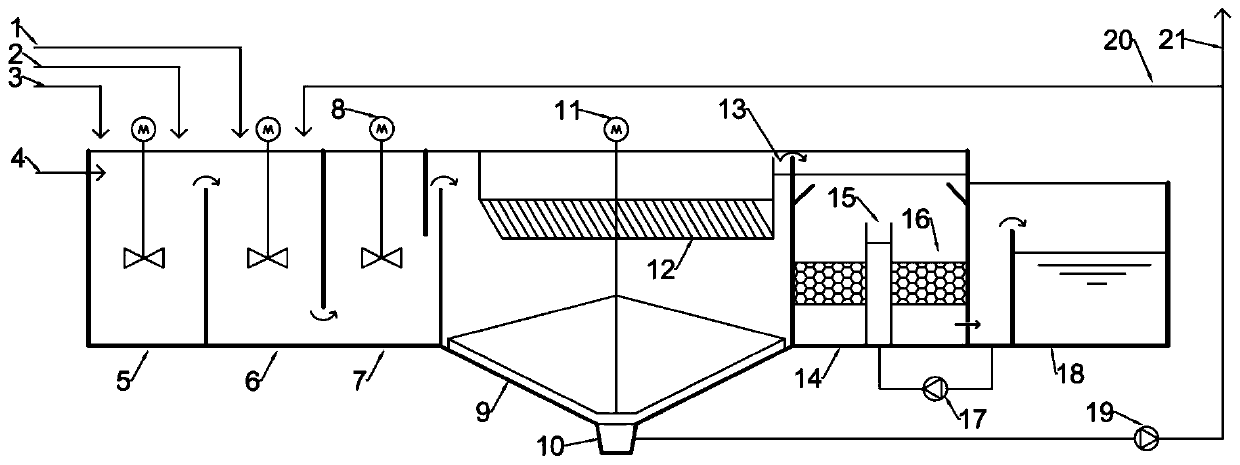

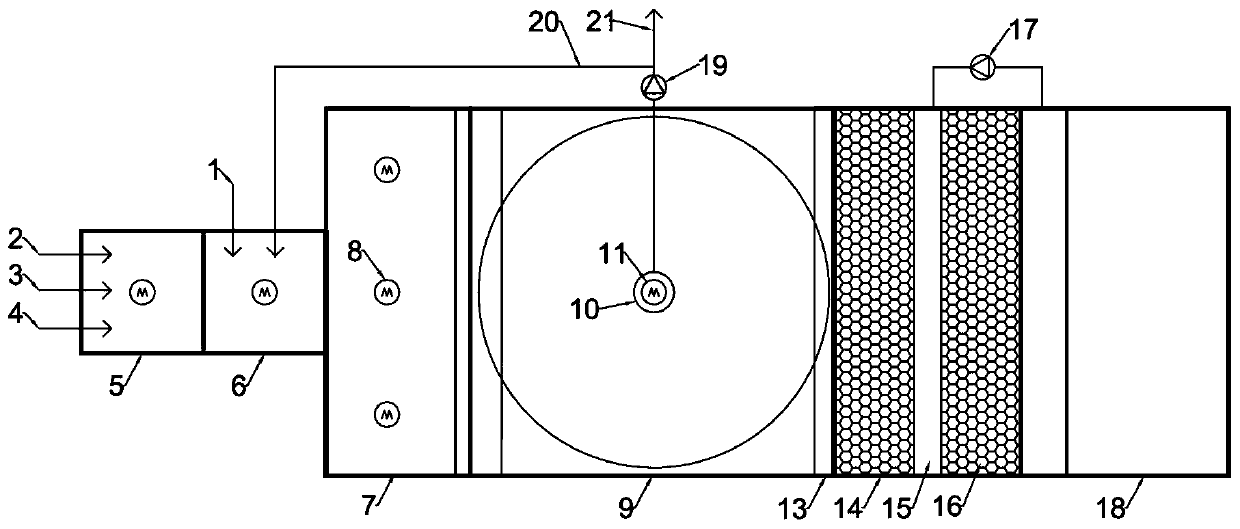

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0033] A method for advanced treatment of pulp and papermaking wastewater, comprising the following steps:

[0034] (1) Build a flocculation reaction tank (divided into three grids, of which 1 grid is coagulation tank 5, 1 grid is flocculation tank 6, and 1 grid is reaction tank 7), a inclined plate sedimentation tank 9, and a V-shaped filter tank 14 , a clear water pool 18. Supporting construction of 1 coagulant pool, 1 flocculant dissolution pool, 1 adsorbent dissolution pool and supporting dosing system;

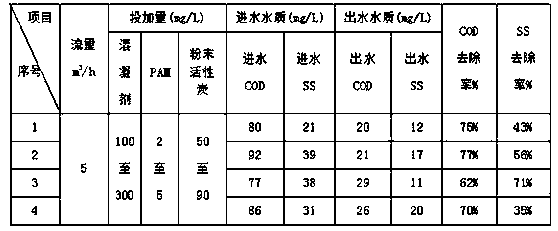

[0035] (2) Take several samples of wastewater 4, select the appropriate amount of coagulant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com