Self-propelled solar sludge drying machine

A dryer and self-propelled technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of low sludge treatment level and complex process of incineration treatment facilities , high operating costs and other issues, to achieve the effect of reducing sludge treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

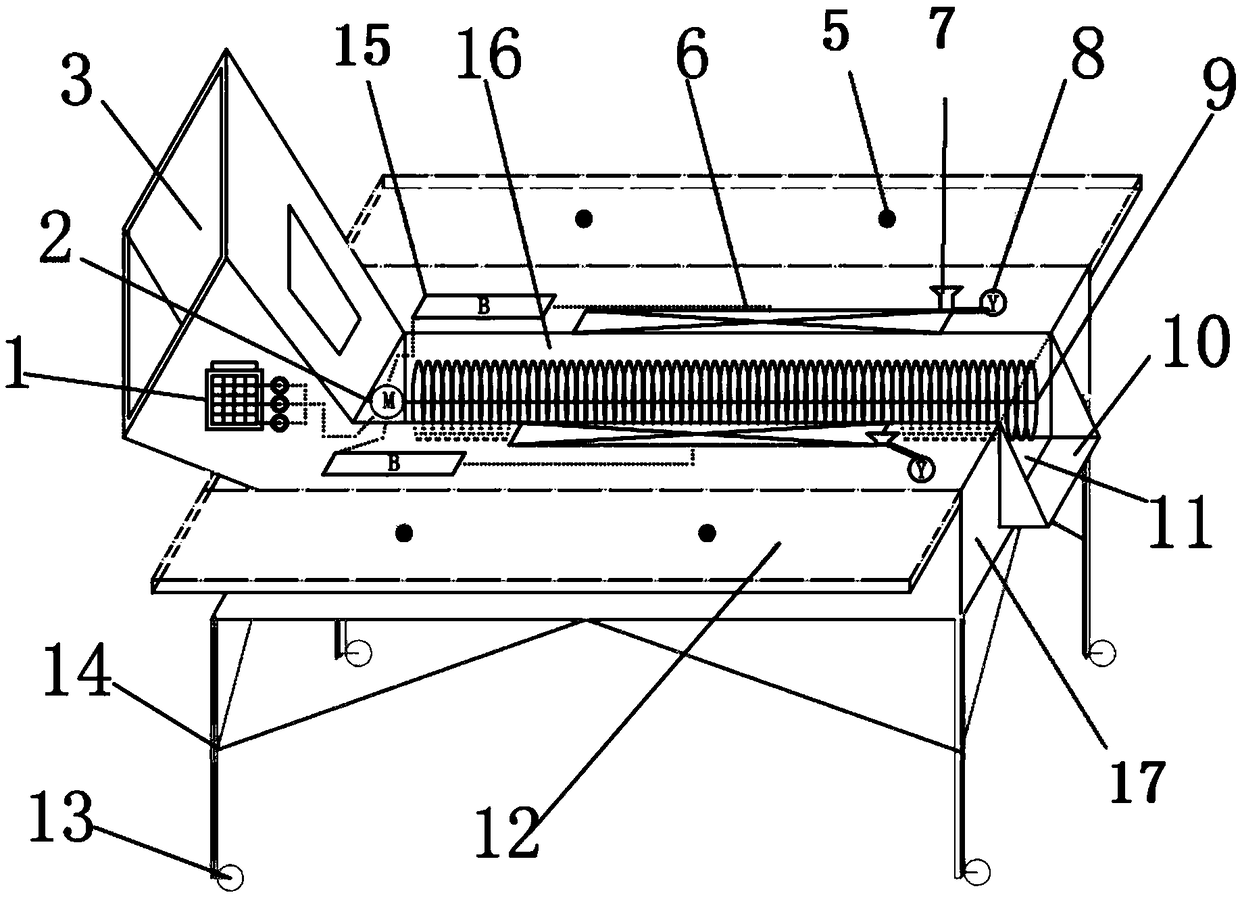

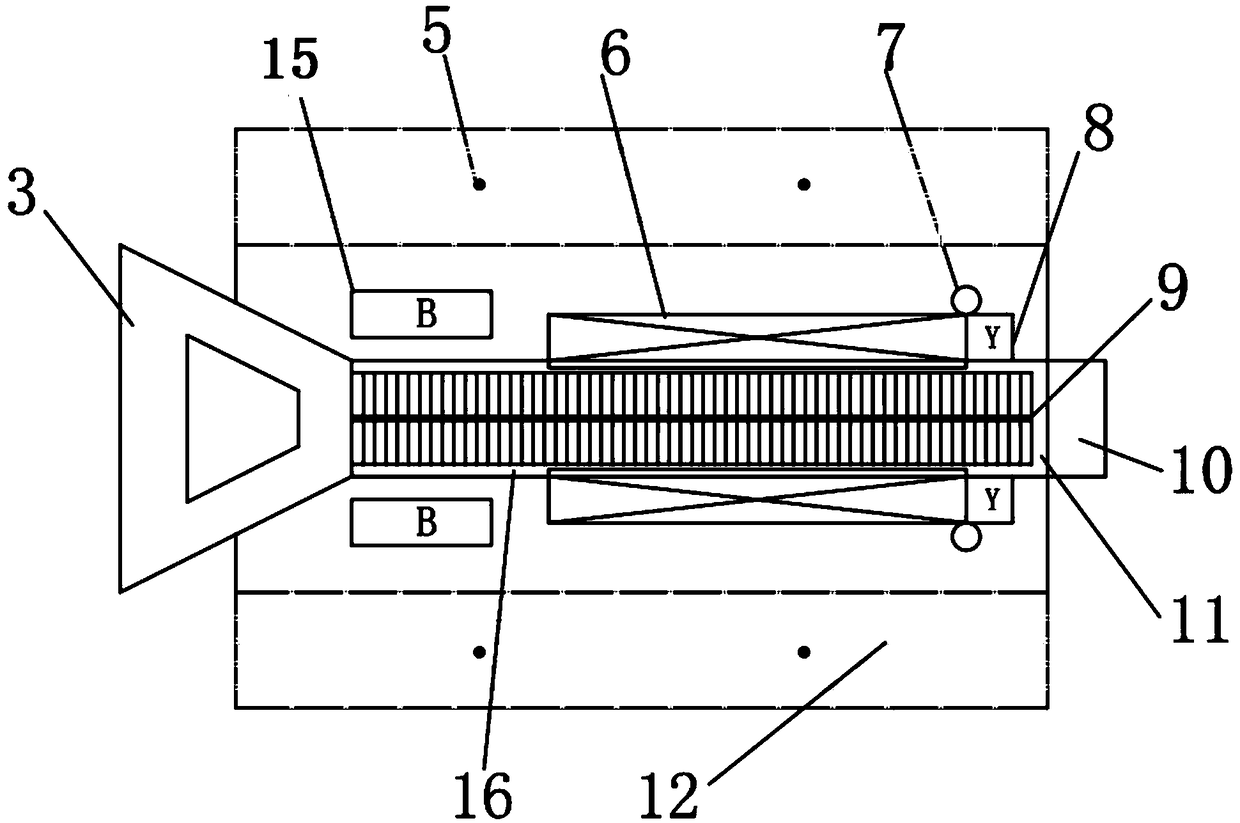

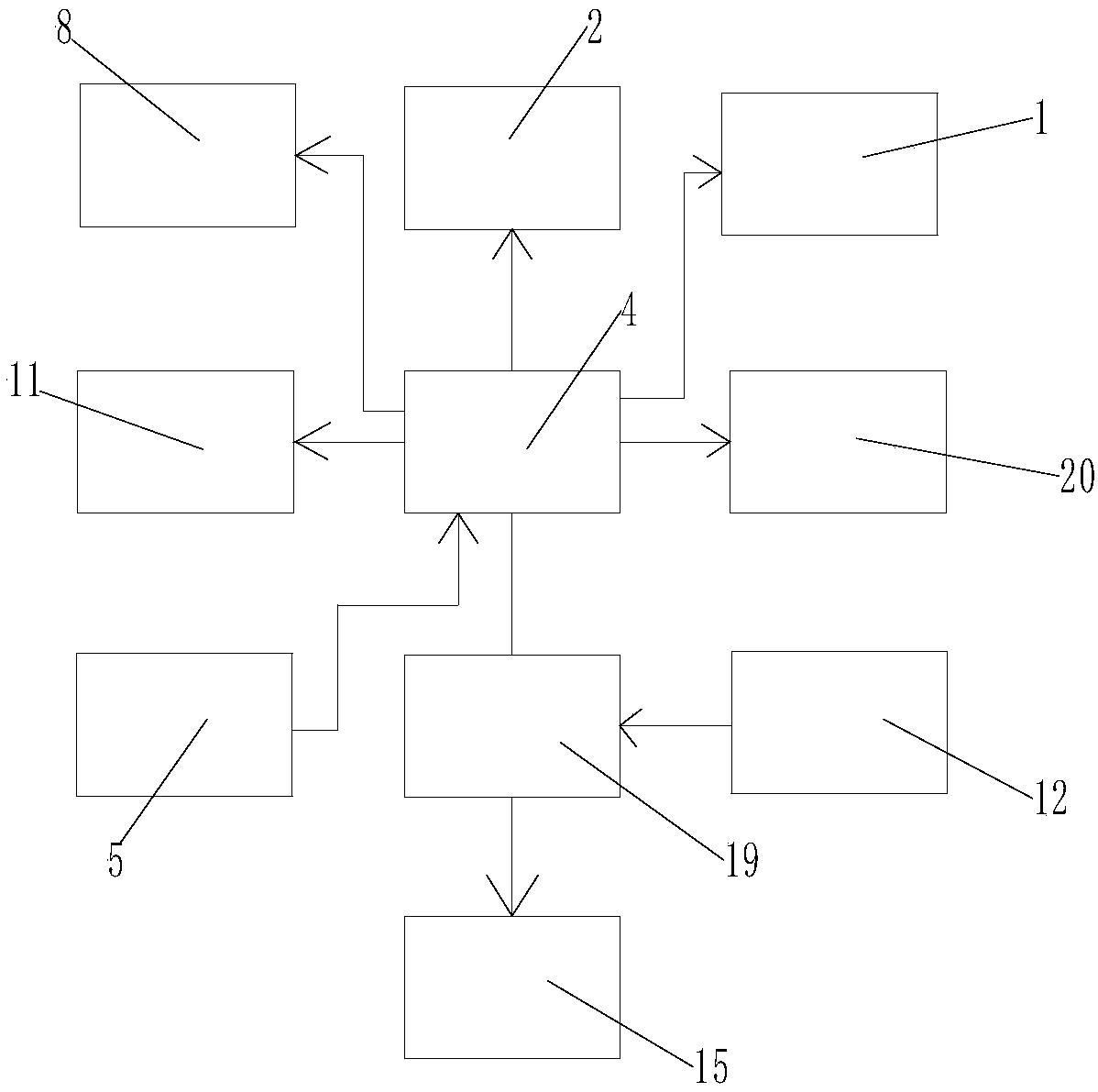

[0039] Such as Figure 1 to Figure 3 As shown, in the first embodiment of the self-propelled solar sludge dryer of the present invention, a workbench 17 is included, and the upper surface of the workbench 17 forms a mud feed tank 18, and the inside of the mud feed tank 18 is provided with a spiral The mud pushing unit is provided with a feeding bin 3 above the feed end of the screw mud pushing unit, and the opposite sides of the screw mud pushing unit are respectively provided with hot air flow generating units, and the upper surface of the workbench 17 is provided with more than one light energy component, The light energy component includes a light energy transmission electric energy component and a light energy heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com