A kind of method for separating element from tin-containing bismuth tellurium solution

A solution and bismuth tellurium technology is applied in the field of hydrometallurgy and multi-element separation, which can solve the problems of low and multi-element tellurium-containing materials, single recovered elements, and difficult to handle grades, and achieves low tellurium-containing grades and high enrichment ratios. , the effect of short transition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

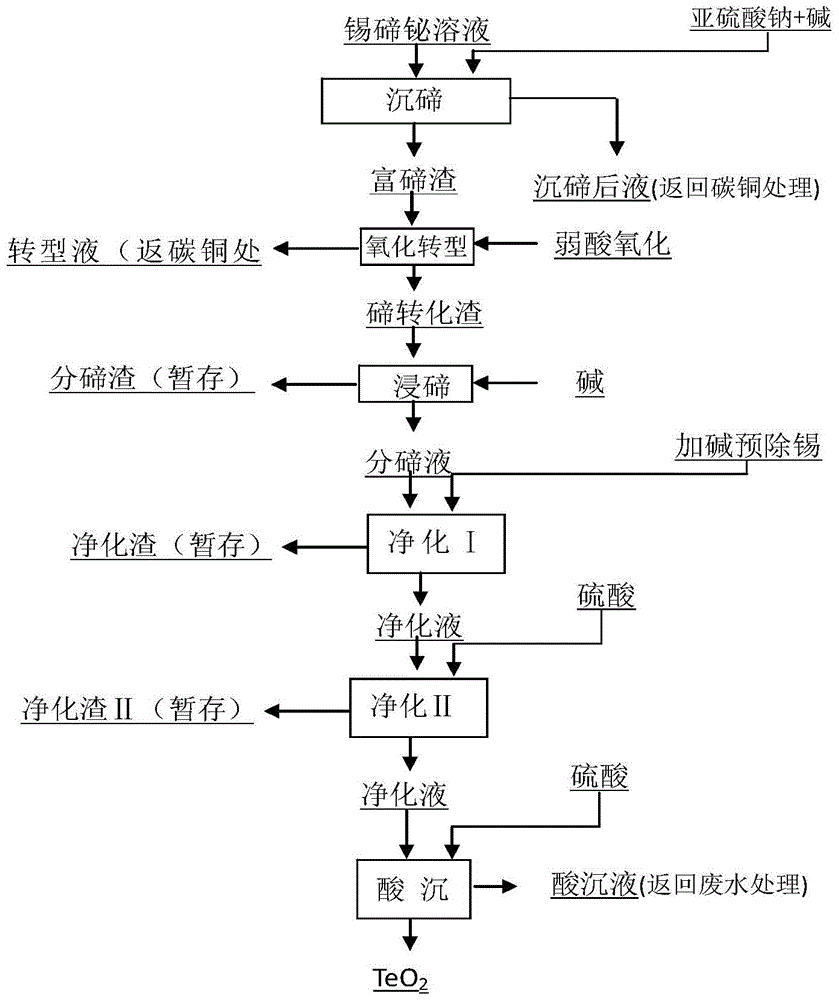

Image

Examples

Embodiment 1

[0039] The composition of the tellurium-containing solution adopted is as follows: Cu 6.80g / L, Te2g / L, Bi0.75g / L%, Sn0.77g / L, Ag36ppm;

[0040] a. Reduction neutralization and precipitation

[0041] The multi-element solution containing tellurium, tin and bismuth is mixed and stirred with the silver deep reduction waste liquid containing 120g / L sodium sulfite and 20g / L sodium hydroxide. The temperature is controlled at 20°C, the time is 1 hour, and the pH value is 3.0. After the reaction, the liquid contains tellurium Below 0.01g / L, the tellurium precipitation rate is above 99%. After the reaction is completed, filter for solid-liquid separation, and the valuable metals tin, copper, bismuth, tellurium, and silver enter the slag phase, which is bismuth-silver slag rich in tin and tellurium , most of the copper enters the solution and is sent to carbon copper for treatment;

[0042] The composition of gold and silver slag rich in tin and tellurium is as follows: Cu 6.18%, Te32....

Embodiment 2

[0059] The composition of the tellurium-containing solution adopted is as follows: Cu 6.80g / L, Te:5g / L, Bi0.75g / L%, Sn0.77g / L, Ag36ppm;

[0060] a. Reduction neutralization and precipitation

[0061] Contain tellurium tin bismuth multi-element solution and contain sodium sulfite 250g / L, the silver deep reduction waste liquid containing sodium hydroxide 10g / L is mixed and stirred, and the control temperature is 60 ℃, and the time is 1.5 hours, and the pH value is 4.0, and the liquid after reaction The tellurium content is less than 0.01g / L, and the tellurium precipitation rate is above 99%. After the reaction is completed, the solid-liquid separation is carried out by filtration, and the valuable metals tin, copper, bismuth, tellurium, and silver enter the slag phase, which is bismuth rich in tin and tellurium. Silver slag, most of the copper enters the solution and is sent to carbon copper for treatment;

[0062] The composition of gold and silver slag rich in tin and telluri...

Embodiment 3

[0079] The composition of the tellurium-containing solution adopted is as follows: Cu 6.80g / L, Te9g / L, Bi0.75g / L%, Sn0.77g / L, Ag36ppm;

[0080] a. Reduction neutralization and precipitation

[0081] The multi-element solution containing tellurium, tin and bismuth is mixed and stirred with a solution containing 50g / L sodium sulfite and 30g / L sodium hydroxide, the temperature is controlled at 99°C, the time is 3 hours, and the pH value is 5.0. After the reaction, the solution contains tellurium at 0.01g / L Below, the tellurium precipitation rate is above 99%. After the reaction is completed, filter for solid-liquid separation, and the valuable metals tin, copper, bismuth, tellurium, and silver enter the slag phase, which is bismuth-silver slag rich in tin and tellurium, and most of the copper enters the slag phase. Solution, sent carbon copper treatment;

[0082] The composition of gold and silver slag rich in tin and tellurium is as follows: Cu 6.18%, Te32.32%, Bi12.77%, Sn13.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com