Purifying agent for removing phosphorus and arsenic in calcium carbide furnace tail gas and its preparation method and application

A technology of calcium carbide furnace tail gas and purification agent, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of large environmental impact, poor purification effect, complex process, etc., and achieve wide pore size distribution and effective removal , good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares cleaning agent I

[0027] (1) Weigh 600 grams of sodium silicate (SiO 2 content 27.1wt%) was dissolved in 2400 ml of deionized water, and 570 g of sodium aluminate (Al 2 o 3 Content 19.3wt%), make SiO in this reaction raw material 2 / Al 2 o 3 The molar ratio is 2.5:1, the obtained gel is stirred for 1 hour, then moved to a 1-liter stainless steel crystallizer, left to age for 2 hours to 4 hours, the temperature of the water bath is raised to 55°C, and the temperature of the water bath is raised to 95°C after 40 hours of crystallization, crystallization 10 hours to complete the reaction. After filtering, the solids were washed three times with 600 ml of deionized water, and dried at 90° C. to obtain A-X intergrowth combined zeolite powder.

[0028] X-ray diffraction analysis (XRD analysis) showed that the combined zeolite contained 30% A-type zeolite and 68% X-type zeolite, and the Si / Al molar ratio was 1.07:1.

[0029] (2) Mix 65 grams of ze...

Embodiment 2

[0030] Embodiment 2 The effect comparative example of three kinds of purifiers

[0031] Utilizing the preparation method of Example 1, using commercially available A-type zeolite instead of the A-X combined zeolite powder obtained in step (1), to prepare Purifier II, using commercially available low-silicon X-type zeolite (Si / Al atomic ratio 1.03) Purifier III is prepared by replacing the A-X combined zeolite powder obtained in step (1).

[0032] Three kinds of purifiers were installed in the fixed adsorption bed respectively, and their removal effects on phosphide and arsenide impurities were investigated.

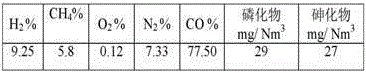

[0033] Table 1 Feed gas composition

[0034]

[0035] Operating conditions: DN25 reaction tube, superficial linear velocity: 0.05m / s, residence time: 20s, operating temperature: 25°C, operating pressure: 0.5MPa, the results are as follows:

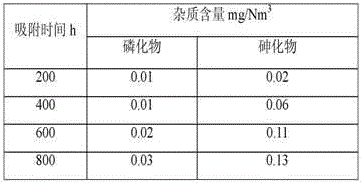

[0036] Table 2 Purifying agent I to the absorption result of phosphorus, arsenic impurity

[0037]

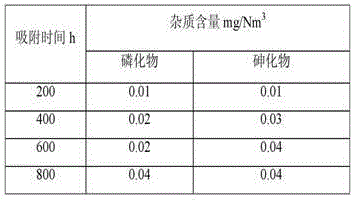

[0038] Table 3 Purifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com