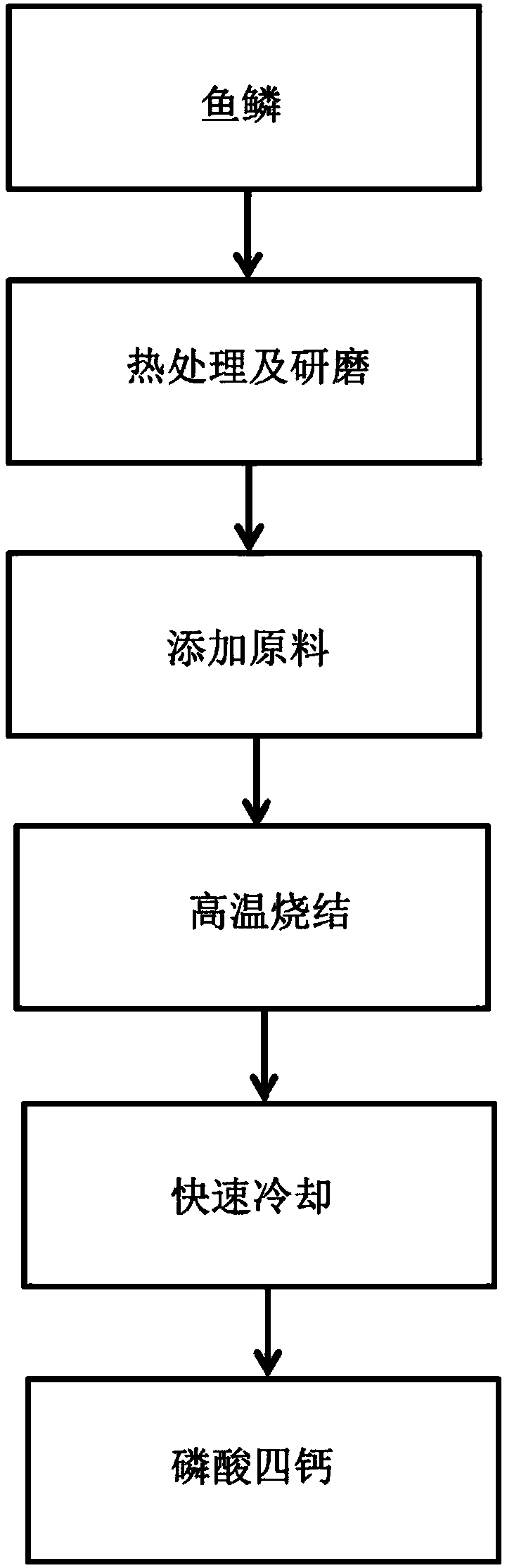

Method for preparing tetracalcium phosphate

A technology of tetracalcium phosphate and phosphorus pentoxide, applied in chemical instruments and methods, phosphorus compounds, medical science and other directions, can solve the problems of low purity and low preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

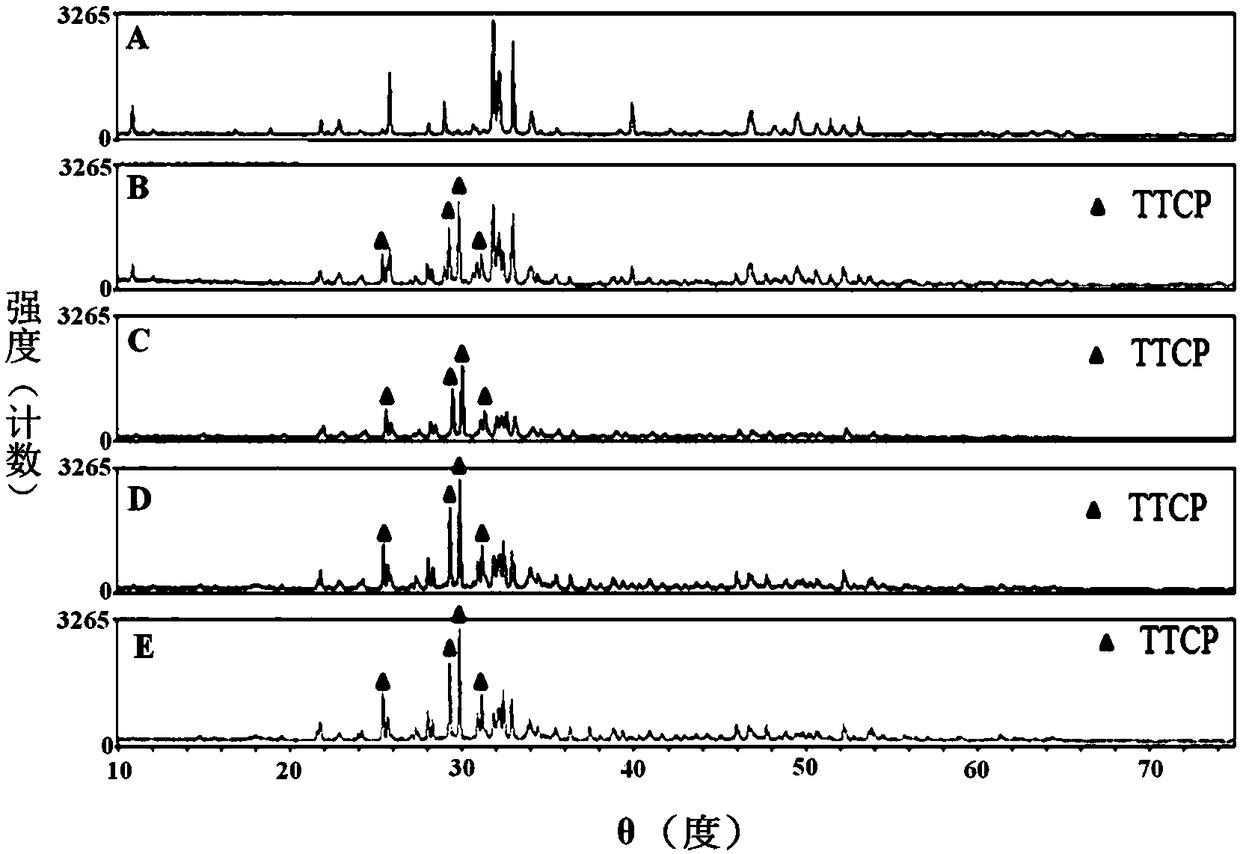

Examples

Embodiment Construction

[0035] The present invention includes, but is not limited to, the above and the following descriptions. The implementation is shown in the following example.

[0036] 1. Materials and methods

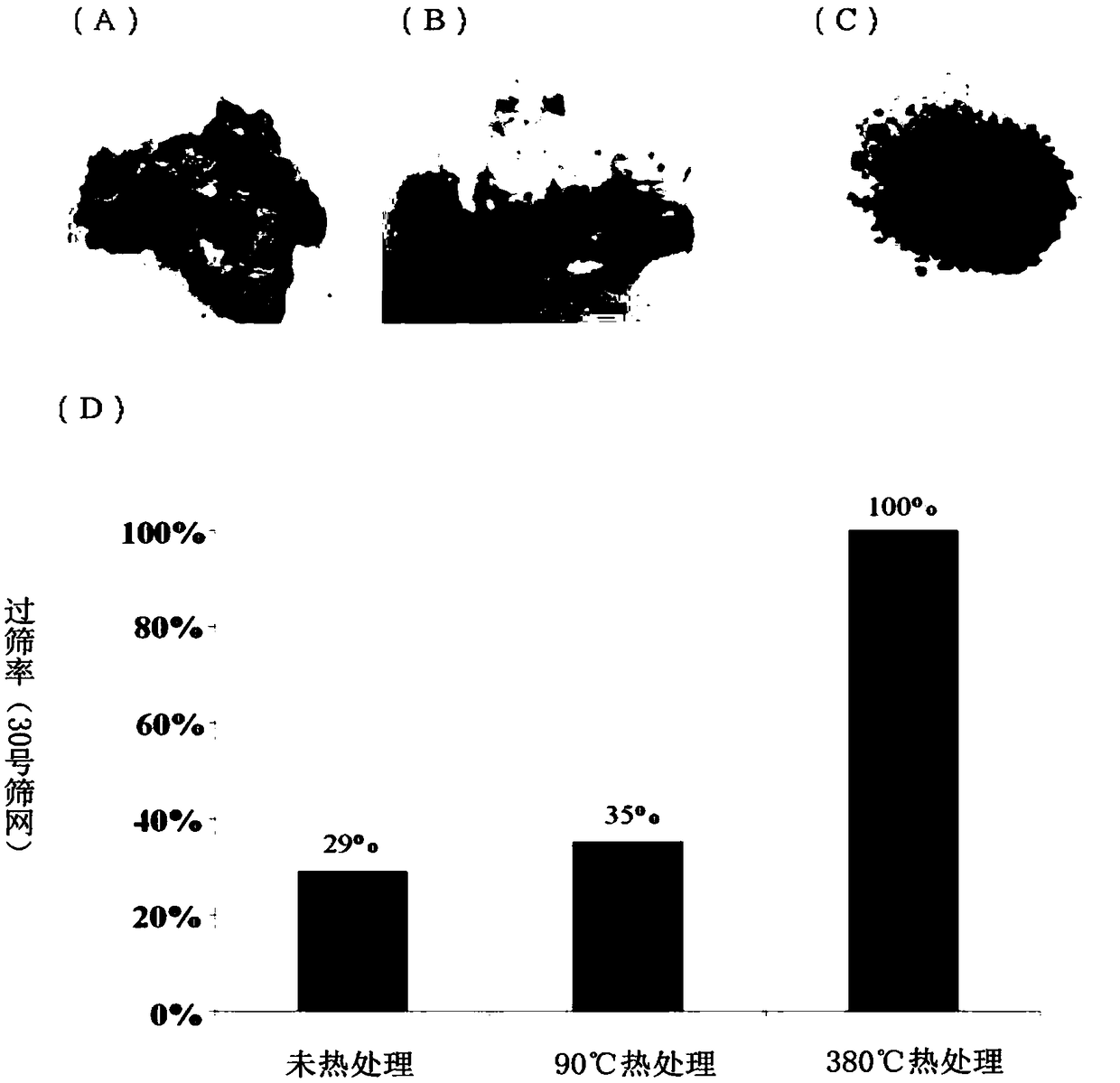

[0037] (a) Thermal analysis and thermal pretreatment test of fish scales

[0038] The present invention utilizes general fish scales to be used as raw materials for preparing tetracalcium phosphate (TTCP) powders. Therefore, in order to understand the characteristics that heat-treated fish scales can be crushed into powder by grinding equipment, the present invention utilizes a thermogravimetric / thermal difference analyzer (TG / DTA, Hitachi TG7200) To investigate the thermal cracking characteristics of fish scales, the temperature of the sample was raised from 25°C to 600°C; the heating rate was 10°C / min. The heat-treated fish scales were ground for 5 minutes with crushing and grinding equipment and sieved with a No. 30 sieve (ASTM No.30mesh). The effects of fish scales treated at diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com