3D printing material for medical bone tissue regeneration, and preparation method of 3D printing material

A 3D printing and bone tissue technology, applied in the field of 3D printing materials, can solve the problems of low mechanical strength, poor water solubility, fast dissolution and absorption, etc., and achieve the effect of good biocompatibility and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A 3D printing material for medical bone tissue repair, which consists of:

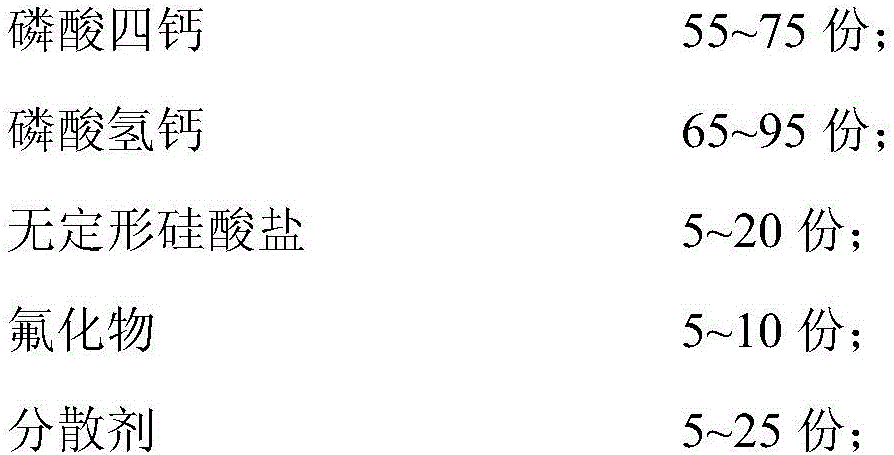

[0034] (1) Powder material components:

[0035]

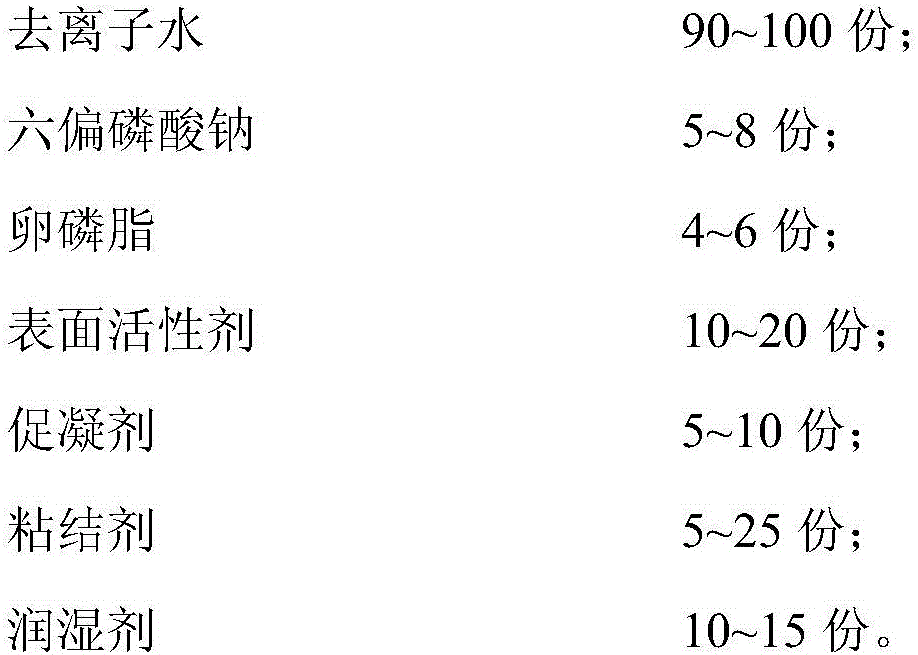

[0036] (2) Components of the bonding solution:

[0037]

[0038]

[0039] Production process: (a) Use a dry powder mixer to mix various components of the powder material, and then use a grinder to grind until the particle size is 1-10 microns, that is, the powder material 1# for 3D printing is obtained. (b) Put all kinds of non-aqueous components in the bonding solution into deionized water under the condition of stirring, stir until the system is completely clear and transparent, and finally stand still to prepare the bonding solution 1# for 3D printing.

Embodiment 2

[0041] A 3D printing material for medical bone tissue repair, which consists of:

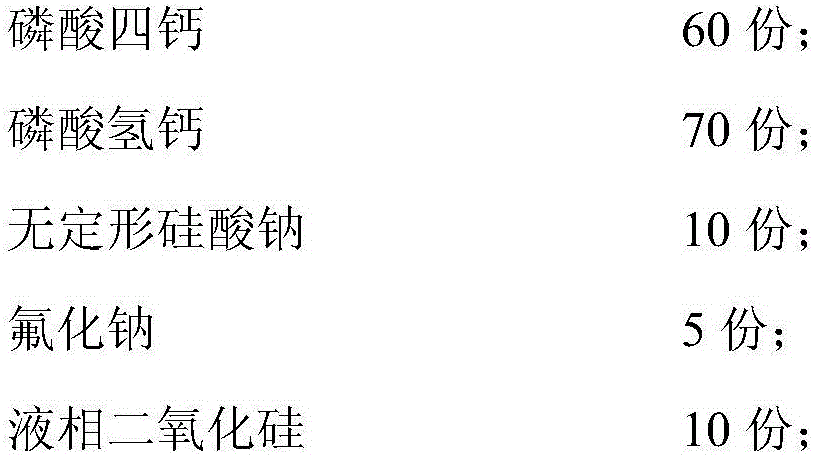

[0042] (1) Powder material components:

[0043]

[0044](2) Components of the bonding solution:

[0045]

[0046] According to the production process of Example 1, 3D printing powder material 2# and bonding solution 2# were prepared.

Embodiment 3

[0048] A 3D printing material for medical bone tissue repair, which consists of:

[0049] (1) Powder material components:

[0050]

[0051]

[0052] (2) Components of the bonding solution:

[0053]

[0054] According to the production process of Example 1, 3D printing powder material 3# and bonding solution 3# were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com