Strontium-calcium composite bone cement and preparation method thereof

A technology of bone cement and calcium nitrate, applied in the field of bone tissue engineering, can solve the problems of restricting wide application and slow degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

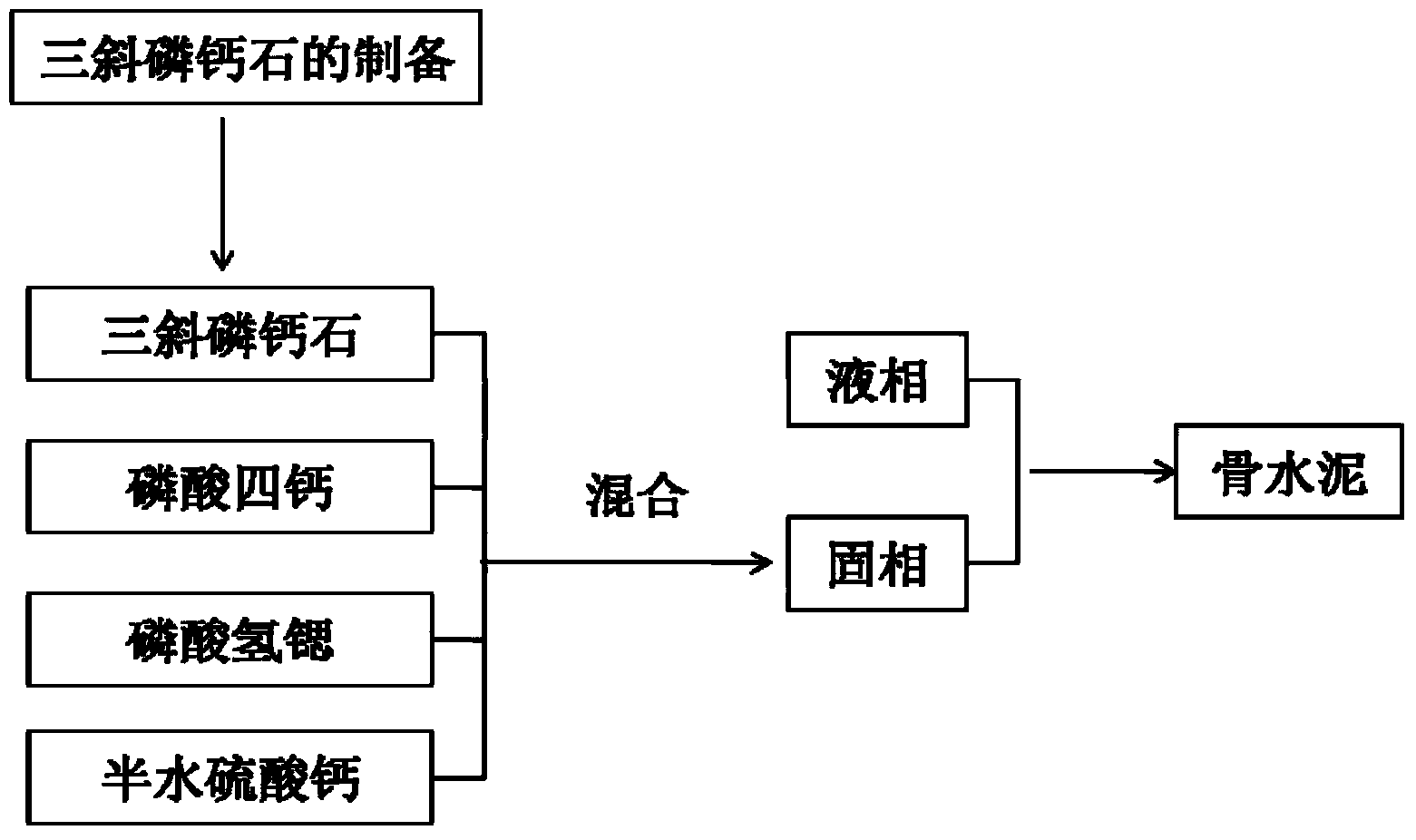

Method used

Image

Examples

Embodiment 1

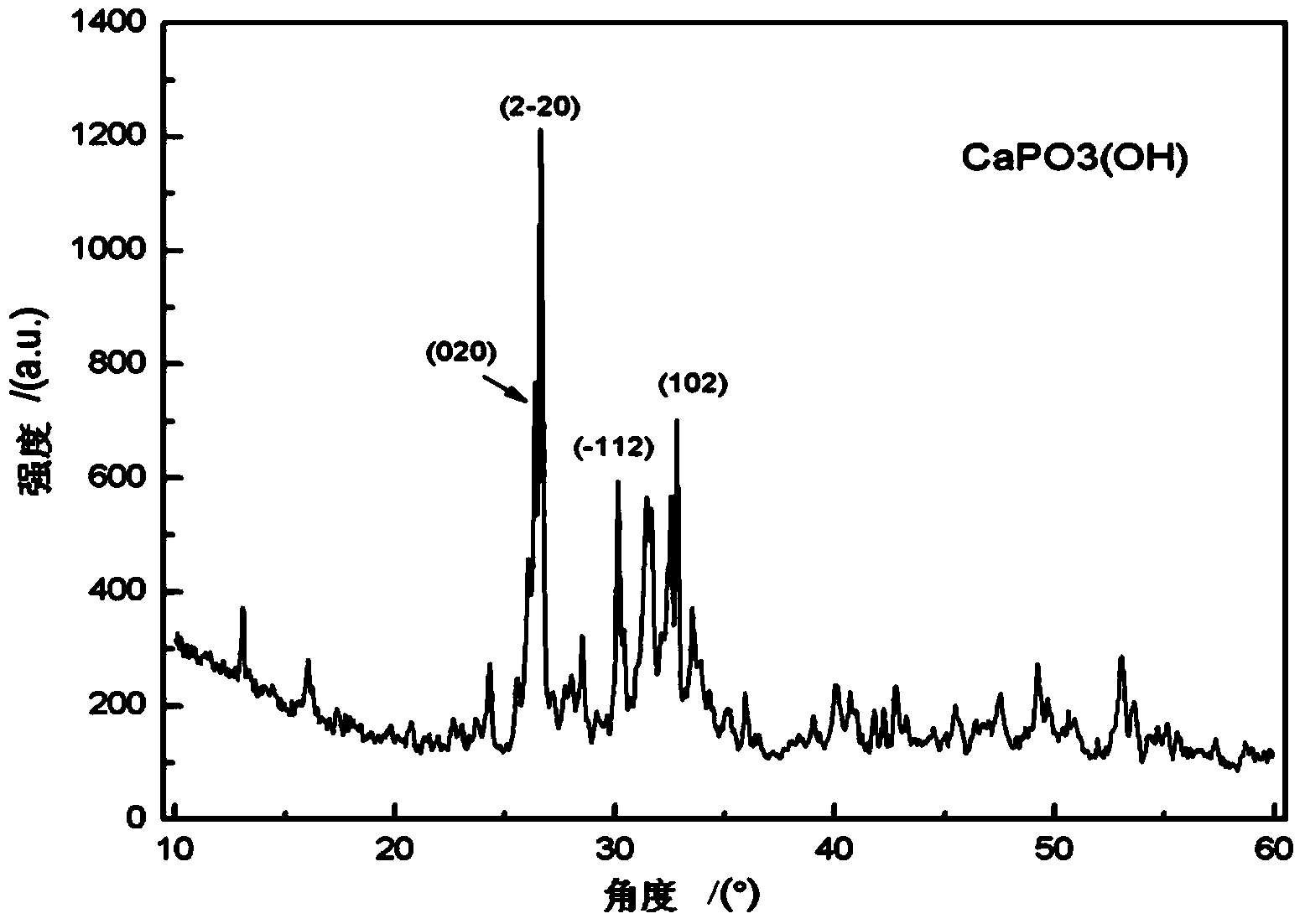

[0029] (1) Preparation of monetite whiskers: configure 0.5mol / L calcium nitrate solution (200ml calcium nitrate mole is 0.5×0.2=0.1mol), add 0.6mol urea (add to mix and stir to fully dissolve, then add 0.5 200ml of mol / L diammonium hydrogen phosphate solution, mixed and stirred to obtain a suspension; then concentrated nitric acid (65-68%) was added to the suspension, the solution became clear, and the pH value was adjusted to 2, and the clear solution was dissolved at 100 React at a constant temperature in a water bath at ℃ for 2 hours, pour off the supernatant, add distilled water to wash repeatedly to remove impurity ions, and filter with suction to obtain a white precipitate. At 100°C, dry at a constant temperature and grind to obtain a powder product. The prepared product was characterized by XRD. as attached figure 1 As shown, the diffraction peak corresponds well to the standard peak (PDF09-0080), and it can be determined that the prepared product is monetite whisker. ...

Embodiment 2

[0033] (1) Preparation of monetite whiskers: configure 200ml of 0.3mol / L calcium nitrate solution, add 0.3mol urea to mix and stir to fully dissolve, then add 200ml of 0.3mol / L diammonium hydrogen phosphate solution, mix and stir Obtain a suspension; then add concentrated nitric acid (65-68%) into the suspension, the solution becomes clear, adjust the pH value to 2.5, react the clear solution at a constant temperature in a water bath at 90°C for 2.5 hours, and pour off the supernatant , add distilled water to wash repeatedly to remove impurity ions, filter with suction to obtain a white precipitate, dry at a constant temperature at 90°C, and grind to obtain a powder product. The product was subjected to phase analysis according to the method of Example 1.

[0034] (2) Preparation of bone cement: at room temperature, weigh 4.0gCSH (80%), 0.70gTTCP (14%), 0.15g monetite whiskers (3%) and 0.15gSrHPO4 (3%) respectively, mix Uniform; measure 2g of distilled water, stir and mix for...

Embodiment 3

[0036] (1) Preparation of monetite whiskers: configure 200ml of 0.05mol / L calcium nitrate solution, add 0.04mol urea to mix and stir to fully dissolve, then add 200ml of 0.05mol / L diammonium hydrogen phosphate solution, mix and stir Obtain a suspension; then add concentrated nitric acid to the suspension, the solution becomes clear, adjust the pH value to 3, and react the clear solution in a water bath at 80°C for 3 hours at a constant temperature, pour off the supernatant, add distilled water to wash and remove repeatedly Impurity ions were obtained by suction filtration to obtain a white precipitate, which was dried and ground at a constant temperature at 90°C to obtain a powder product. The product was subjected to phase analysis according to the method in Example 1.

[0037] (2) Preparation of bone cement: at room temperature, weigh 3.5g CSH (70%), 1.095g TTCP (21.9%), 0.4g monetite whiskers (8%) and 0.005g SrHPO4 (0.1%), mix well ; Measure 1.67g of 0.01mol / L polyvinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com