Bone cement formula and bioresorbable hardened bone cement composites prepared with the same

A composite material and bone cement technology, which can be used in tissue regeneration, surgical adhesives, medical science, etc., and can solve problems such as prolonging setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

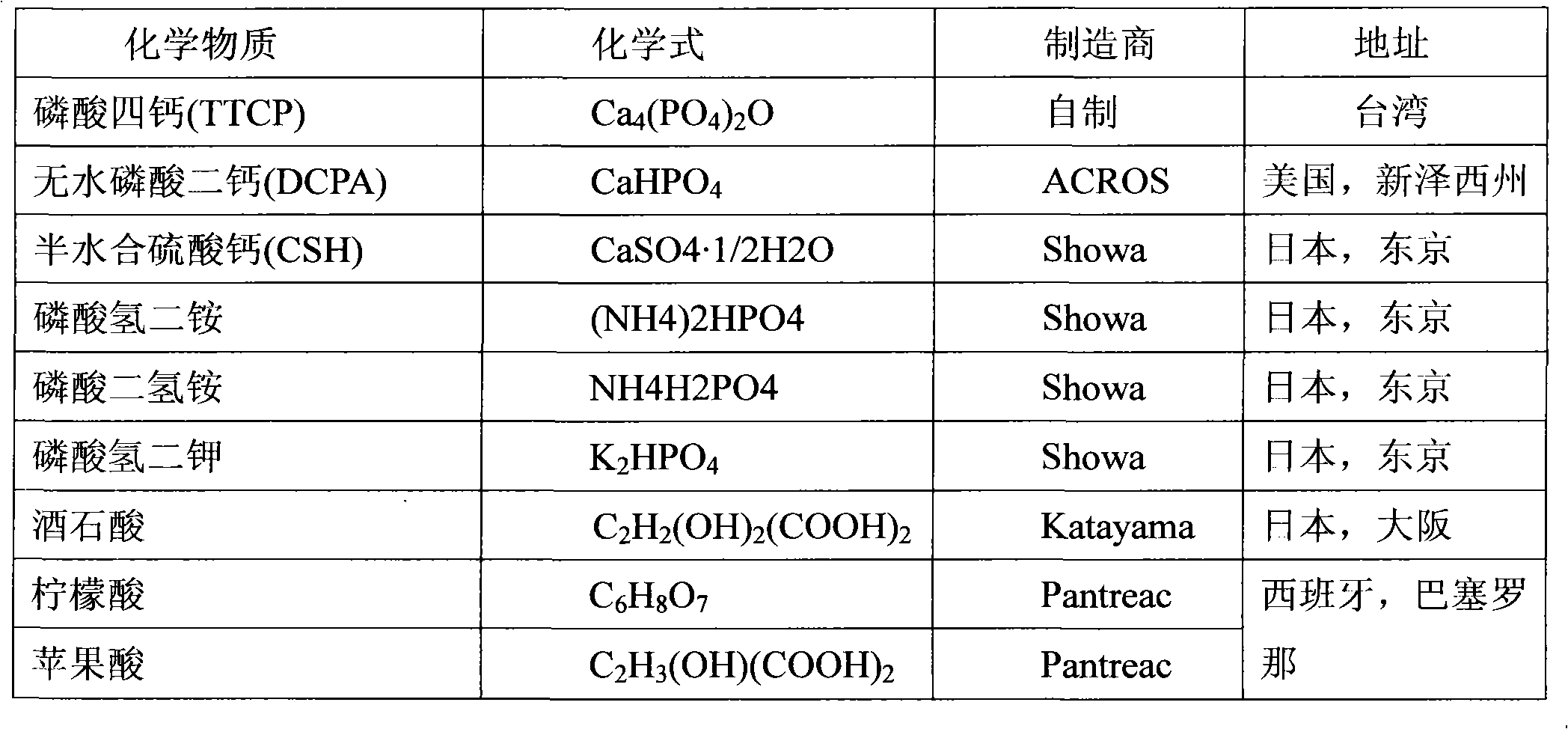

[0044] Preparation of TTCP powder

[0045] TTCP powder adopts the method proposed by Brown and Epstein [Journal of Research of the National Bureau of Standards-A Physics and Chemistry 6 (1965) 69A 12], from dicalcium pyrophosphate (Ca 2 P 2 o 7 ) (Sigma Chem.Co., St.Louis, MO, USA) and calcium carbonate (CaCO 3 ) (Katayama Chem.Co., Japan, Tokyo) reaction and self-made.

[0046] TTCP powder by adding Ca 2 P 2 o 7 Powder with CaCO 3 The powder was prepared by uniform mixing for 12 hours. Ca 2 P 2 o 7 Powder with CaCO 3 The mixing ratio of the powders was 1:1.27 (weight ratio), and the powder mixture was heated to 1400° C. to react the two powders to form TTCP.

[0047] Preparation of TTCP / DCPA / CSH Composite Paste

[0048] Mix an appropriate amount of TTCP and DCPA powder uniformly in a ball mill, and then uniformly mix with an appropriate amount of CSH powder. Mix the obtained TTCP / DCPA / CSH mixed powder with the desired coagulation solution (for example, 0.6M (NH ...

Embodiment 1

[0085] Embodiment 1: (TTCP / DCPA) / CSH cement and various coagulation solutions

[0086] Table 5: 75 wt% phosphate (TTCP / DCPA) / 25 wt% CSH composite cement

[0087]

[0088]

[0089] The data shown in Table 5 can be summarized as follows:

[0090] 1. K 2 HPO 4 - WT / ST of derived hardened cement composites is too short and CS is low.

[0091] 2. (NH 4 )H 2 PO 4 - Derived hardened cement composites have reasonable WT / ST, but disperse after immersion in Hanks' solution.

[0092] 3. NaH 2 PO 4 2H 2 O-derived hardened cement composites have reasonable WT / ST, but are too acidic and have low strength.

[0093] 4. In all coagulation solutions tested, (NH 4 ) 2 HPO 4 Generate the highest CS.

[0094] 5. In all (NH 4 ) 2 HPO 4 Among the concentrations, 0.6M gives the highest CS (41MPa).

Embodiment 2

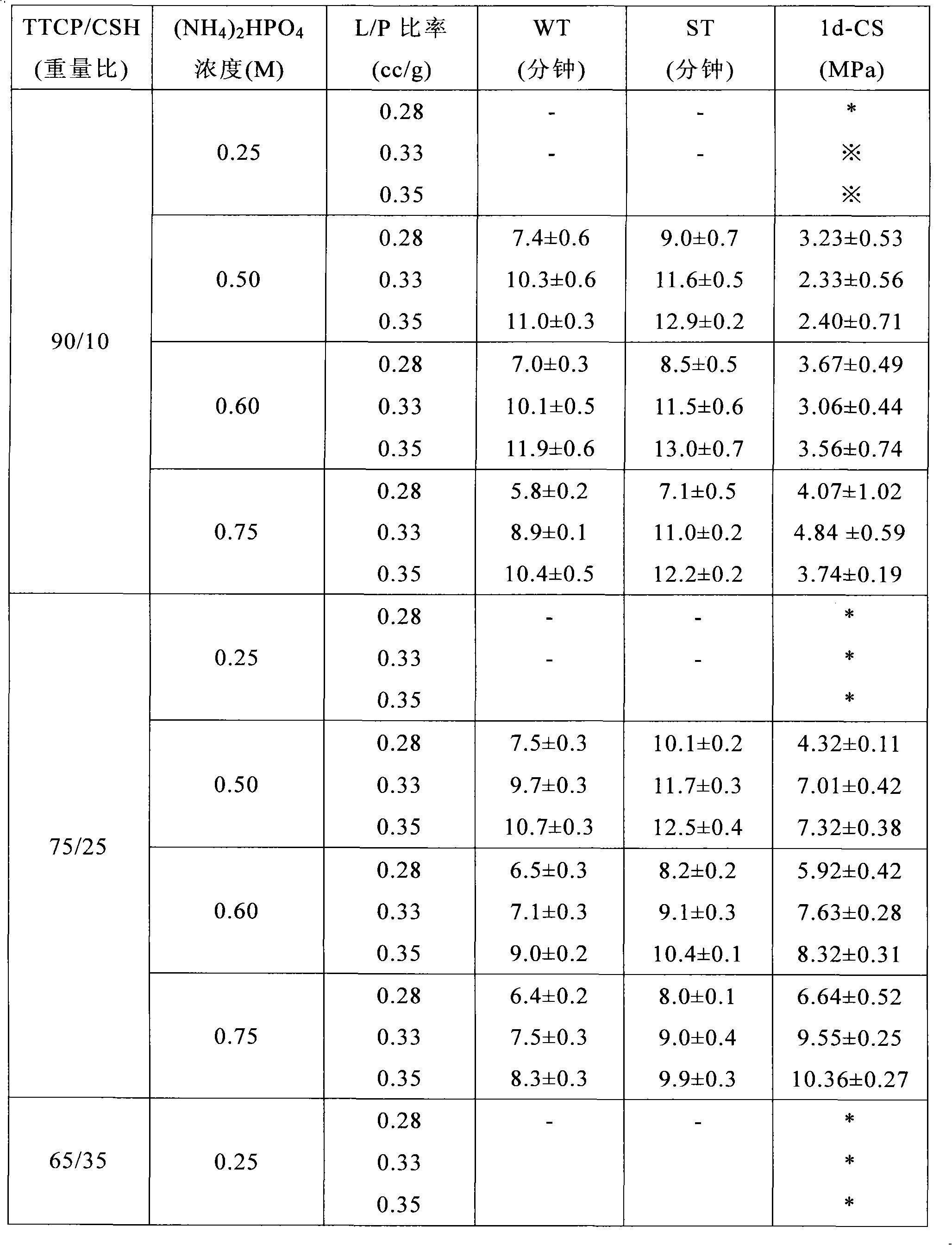

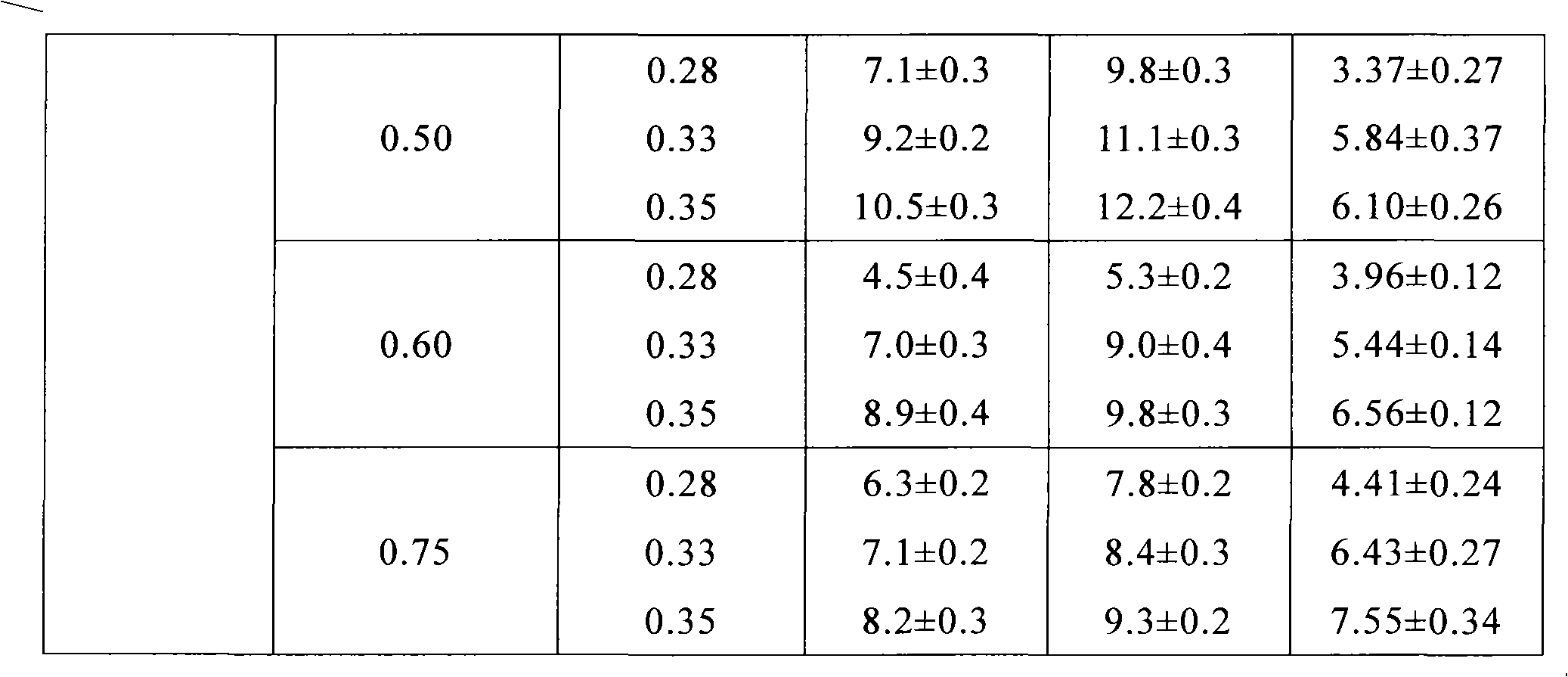

[0095] Embodiment 2: with 0.60M (NH 4 ) 2 HPO 4 Mixed TTCP / DCPA / CSH

[0096] Table 6: and 0.60M (NH 4 ) 2 HPO 4 Mixed TTCP / DCPA / CSH

[0097]

[0098]

[0099] In Table 6 (with 0.60M (NH 4 ) 2 HPO 4 Summary of results shown in Mixed TTCP / DCPA / CSH):

[0100] (1) When the CSH content in TTCP / DCPA / CSH cement powder is higher than about 65 wt%, its CS value becomes too low ( 30 MPa), the CSH content should be less than about 35% by weight.

[0101] (2) When 0.60M (NH 4 ) 2 HPO 4 When used as a sclerosing solution, all cytotoxicity values were acceptably greater than 80% for all CSH contents (from about 10% to about 90% by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com