Process of treating refractory organic effluent with free radical and electrically catalyzed reactor therewith

A technology for organic wastewater and free radicals, applied in chemical instruments and methods, oxidized water/sewage treatment, electrochemical water/sewage treatment, etc. Low efficiency and other problems, to achieve the effect of strong controllability of oxidation reaction, low equipment and operating costs, and large processing capacity

Inactive Publication Date: 2007-08-22

BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

View PDF7 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the existing advanced oxidation technologies (AOP) for treating difficult organic wastewater, the conditions for generating free radicals are too harsh, the cost of generating free radicals is too expensive, or the yield of free radicals is too low and the concentration is low , short stabilization time and many other problems, the ultimate treatment of organic wastewater cannot be realized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

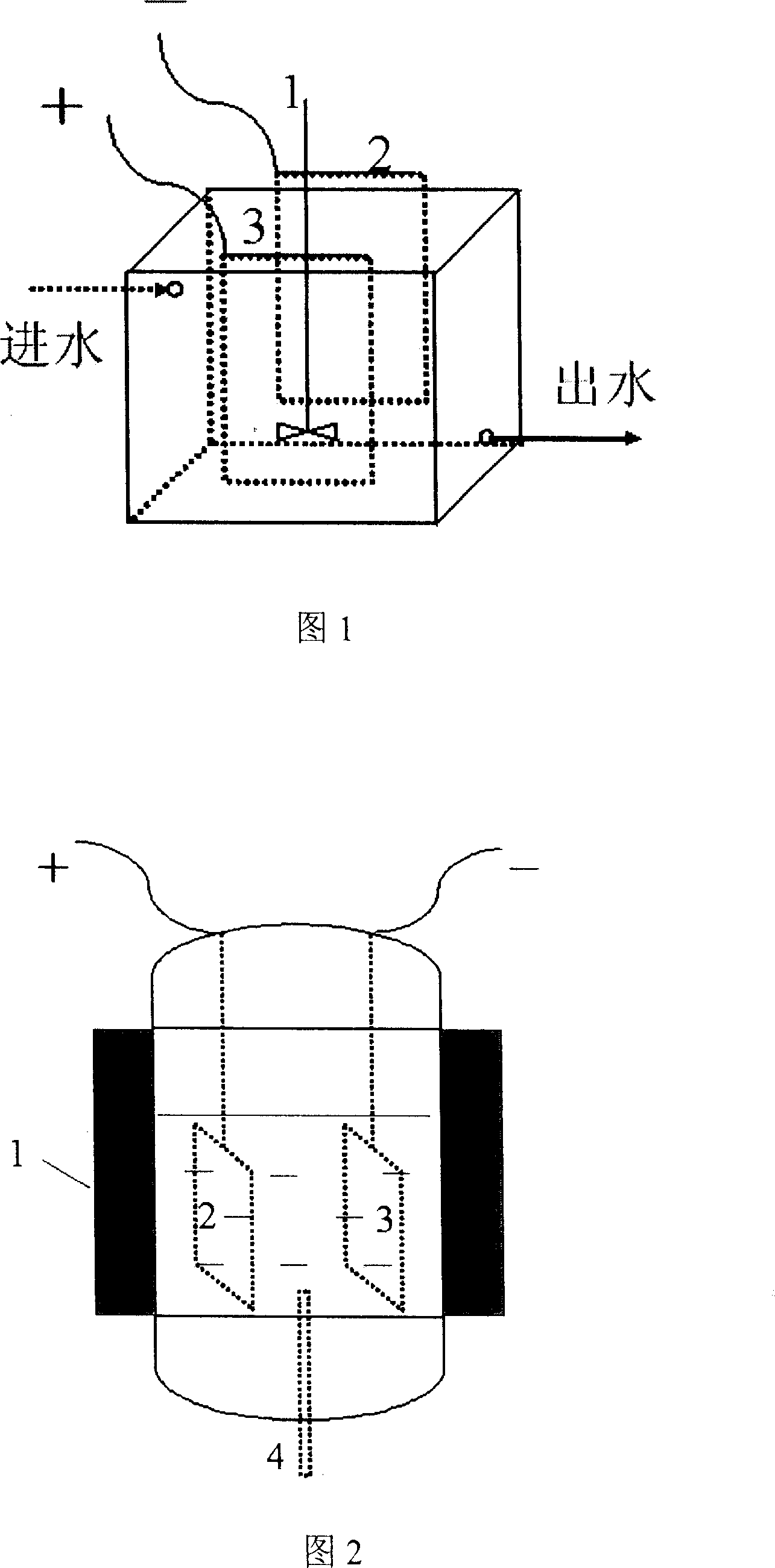

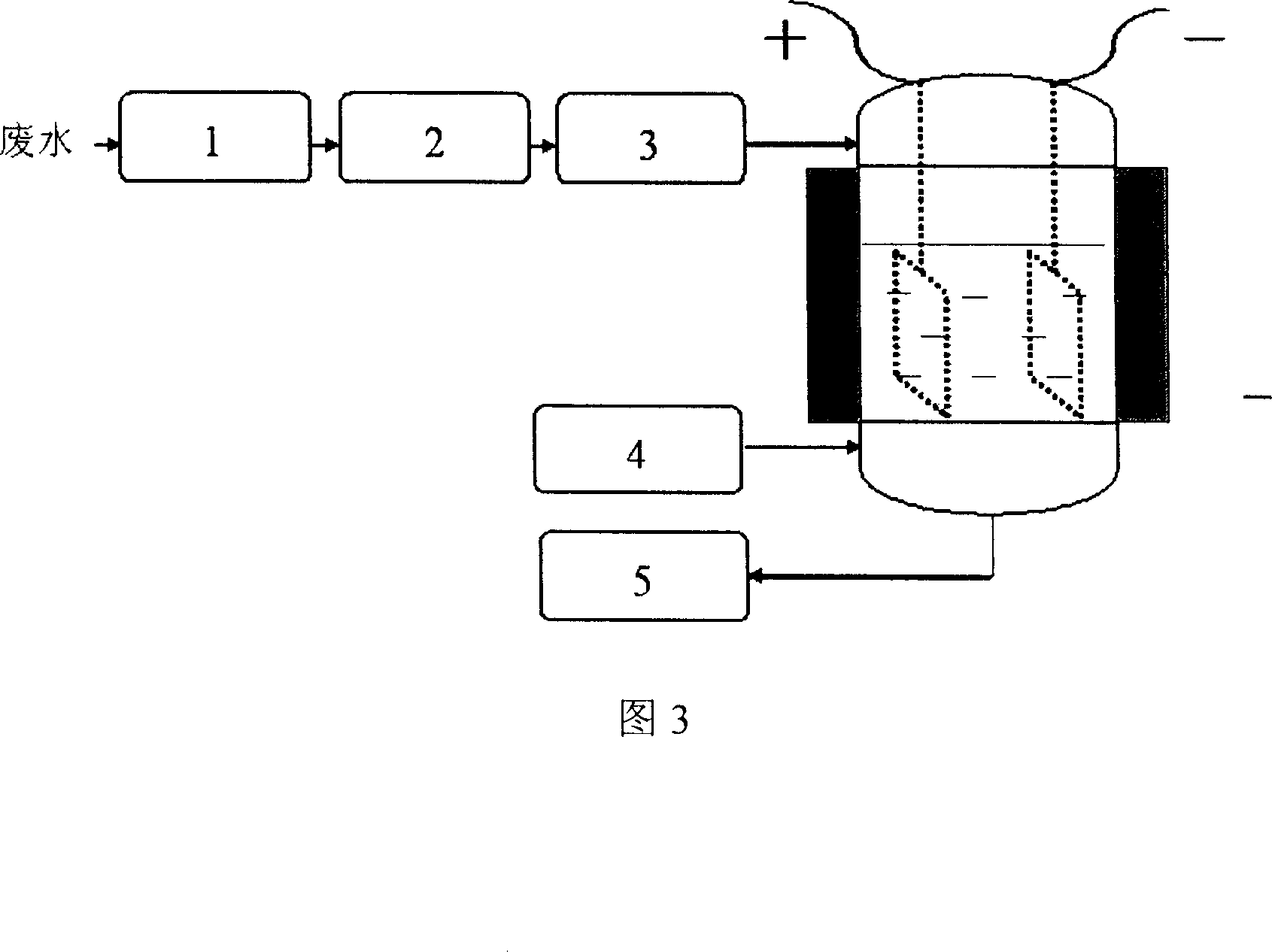

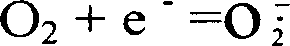

The present invention is process of treating refractory organic effluent with free radical and the electrically catalyzed reactor therewith. The present invention features that in an electrochemically hydrating proton reaction kettle and in the presence of initiator, free hydroxyl radical, superoxide anion free radical, free nitrogen radical, active free oxygen radical, etc are generated circularly and reacted in an electrically catalyzing high pressure reaction kettle with various kinds of refractory organic compounds for efficient decomposition. The present invention has high organic waste water degrading rate and low cost, and is suitable for high concentration organic waste water treatment in papermaking, petrochemical and other industry.

Description

technical field The invention relates to the technical field of high-concentration refractory sewage treatment, and relates to a method for treating highly difficult organic waste water using free radical technology and an electrocatalytic fast reaction device thereof. Background technique High-concentration refractory wastewater has the characteristics of high pollutant content, high toxicity, serious hazards, refractory biodegradation, complex treatment process, and high purification investment and operation costs. A series of problems caused by high-concentration refractory wastewater, such as water pollution, ecological environment deterioration, threats to human health, and hindering the development of related industries, have attracted more and more attention from all walks of life and environmental protection departments of governments at all levels. However, because conventional wastewater treatment methods are difficult to purify or cannot meet the technical and ec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/72C02F1/46C02F101/30

Inventor 梅秀泉苏岳峰赵保路

Owner BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com